A smart water supply system

A technology of water supply system and water affairs, applied in water supply installations, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of consuming manpower, accelerating the rate of corrosion of the water storage tank, and reducing the service life of the water storage tank. , to achieve the effect of improving the degree of cleaning, reducing the corrosion rate and optimizing the use process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

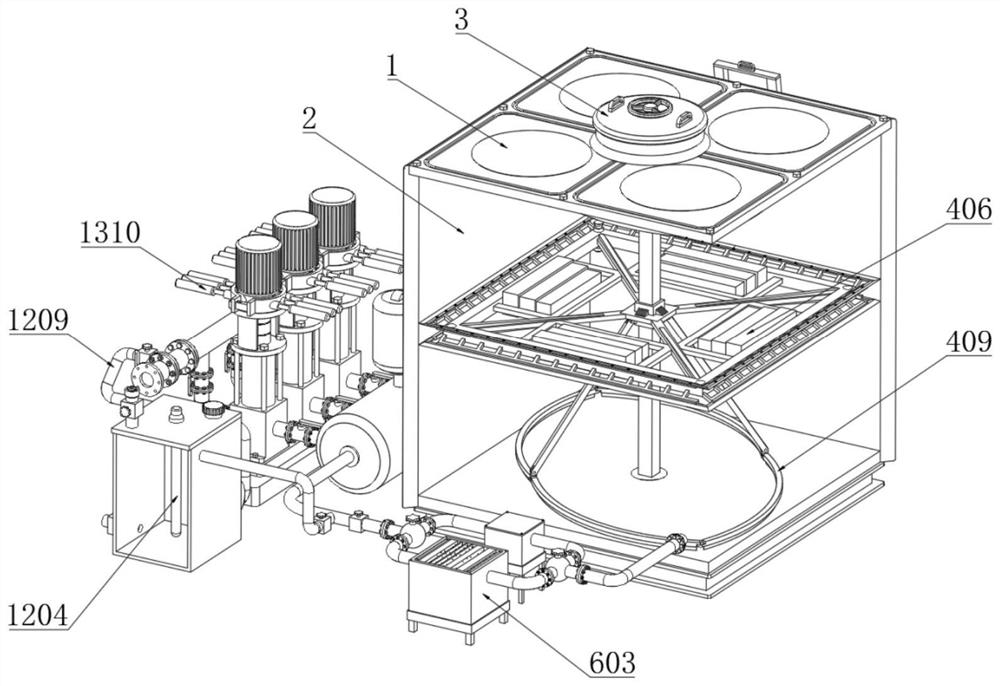

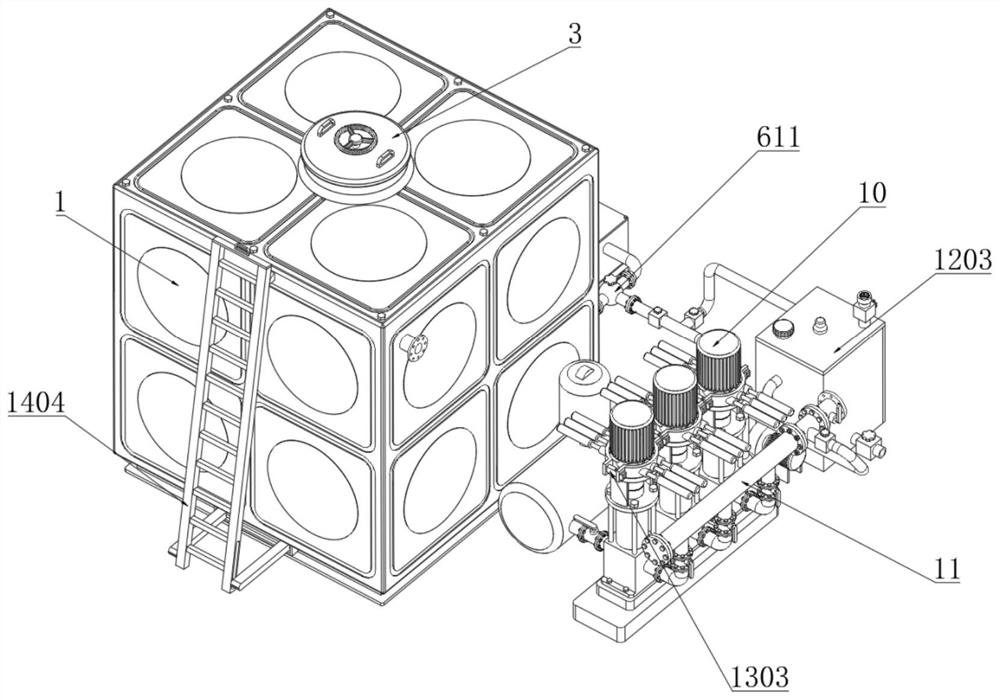

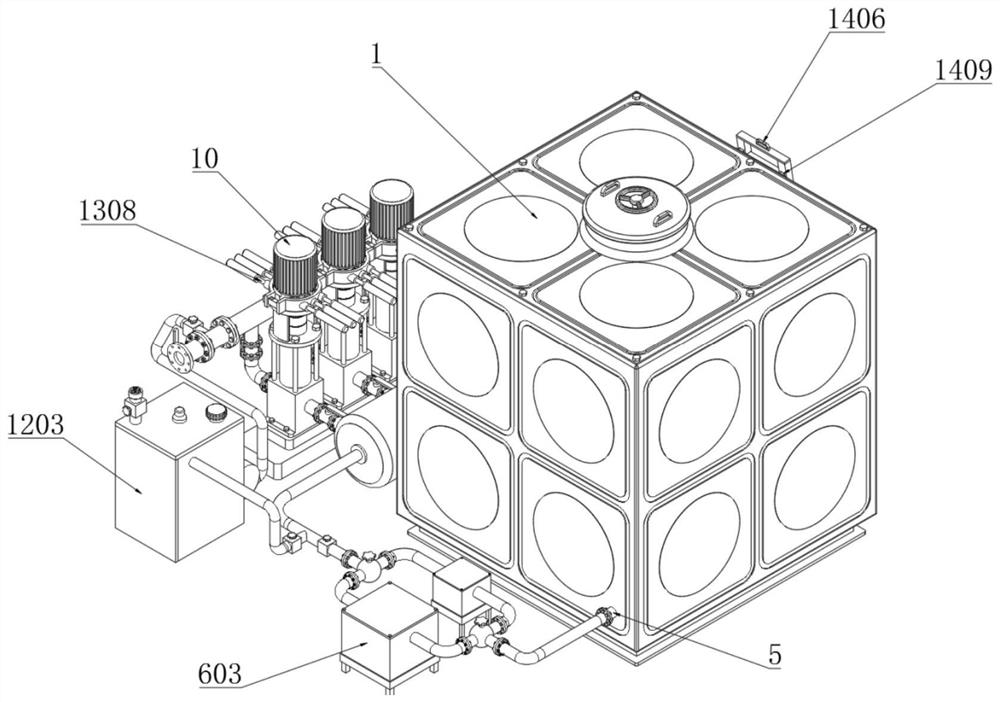

[0039] Example: as Image 6 , 7 , 10-12, including the water tank shell 1, the water tank inner wall cleaning mechanism 4, the continuous disinfection and filtering mechanism 6, the circulating cleaning structure 12, the shock absorption buffer mechanism 13 and the protective storage mechanism, the top wall of the transfer box 1203 of the circulating cleaning structure 12 is fixed. There are two pneumatic lifting cylinders 1211 that act synchronously. The output shaft 1225 of the pneumatic lifting cylinder is fixedly connected with the installation ring plate 1212 inside the transfer box 1203. The upper end of the installation ring plate 1212 is provided with a placement groove 1213, and a bottom is placed in the placement groove 1213. Ring 1214, the inner wall of the bottom ring 1214 is fixed with a brush wire 1215, and the bottom ring 1214 is fixed with a plurality of transmission cylinders 1216, and the two adjacent transmission cylinders 1216 are fixedly connected by at le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com