Heat regenerative type afterheat steam boiler

A waste heat steam and boiler technology, used in steam boilers, steam boiler accessories, steam boiler components, etc., can solve the problems of extremely poor heat exchange effect, difficult to achieve effective heat recovery, etc., to prevent scaling and facilitate mechanical cleaning. , to enhance the effect of heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

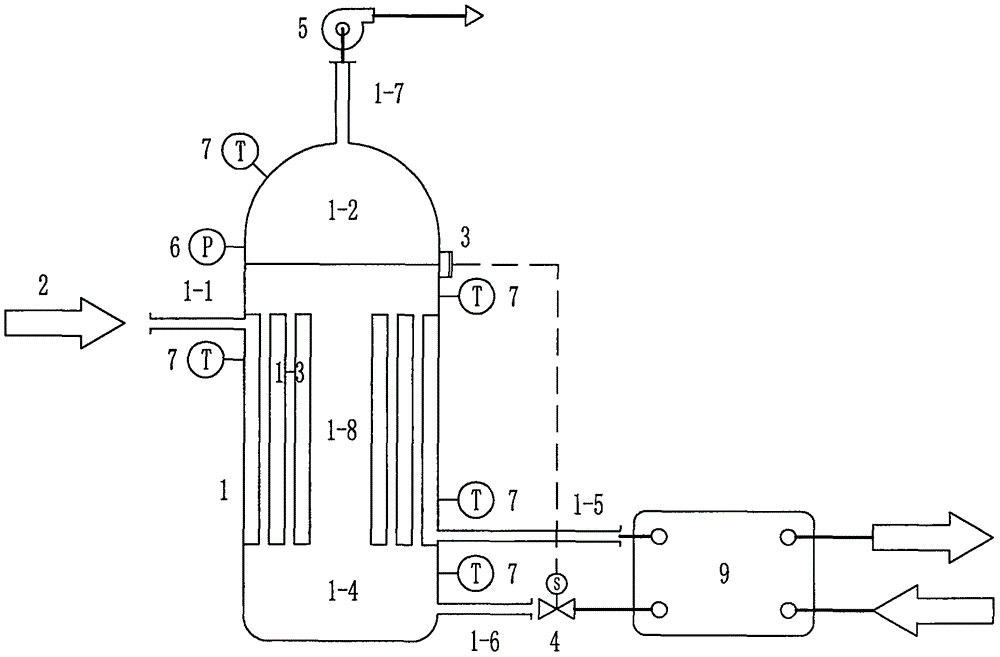

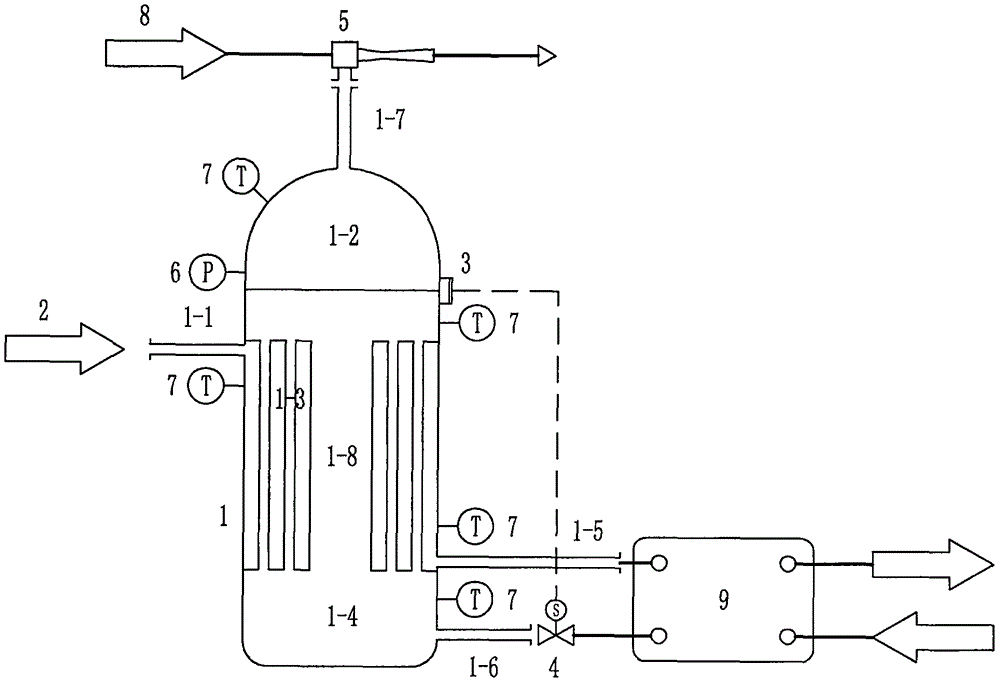

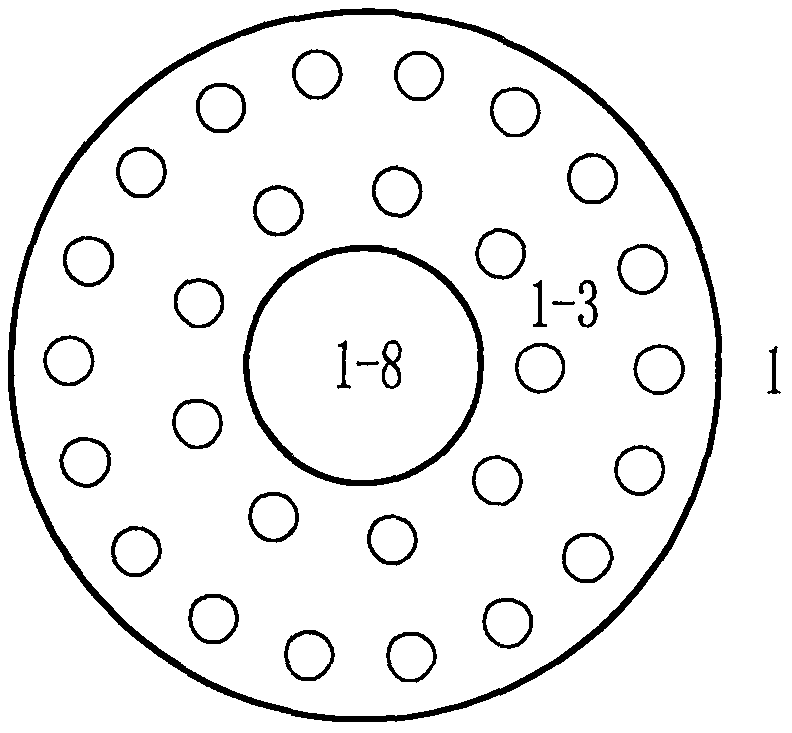

[0042] The embodiment of the heat recovery type waste heat steam boiler proposed by the present invention is attached figure 2 As shown, the description is as follows: It consists of a rising film evaporator 1 with a waste heat recovery capacity of 208kW, vertical installation, and carbon steel pipe siphon circulation countercurrent heating; a stainless steel pipe waste heat medium inlet 1-1 with a diameter of 200mm / wall thickness of 2.5mm; a diameter of 700mm / Hemispherical separation chamber 1-2 with a height of 500mm; inner ring diameter 400mm / height 1500mm / pipe diameter 19mm distributed vertical siphon heating tube clusters 1-3; diameter 700mm / height 250mm hemispherical shunt chamber 1-4; Stainless steel pipe with a diameter of 200mm / wall thickness 2.5mm outlet 1-5 for waste heat medium; stainless steel pipe with a diameter of 20mm / wall thickness 1.5mm / length 200mm for softening water inlet 1-6; stainless steel pipe with a diameter of 200mm / wall thickness 2.5mm for water v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com