Arrangement for the sealing of channel sections in a hot or cold runner

A technology of distributors and cold runners, which is applied in the system field of the runner section enclosed in hot runner distributors or cold runner distributors, can solve problems such as occupying a lot of structural space, achieve easy mechanical cleaning, avoid The effect of dead ends, simple placement and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

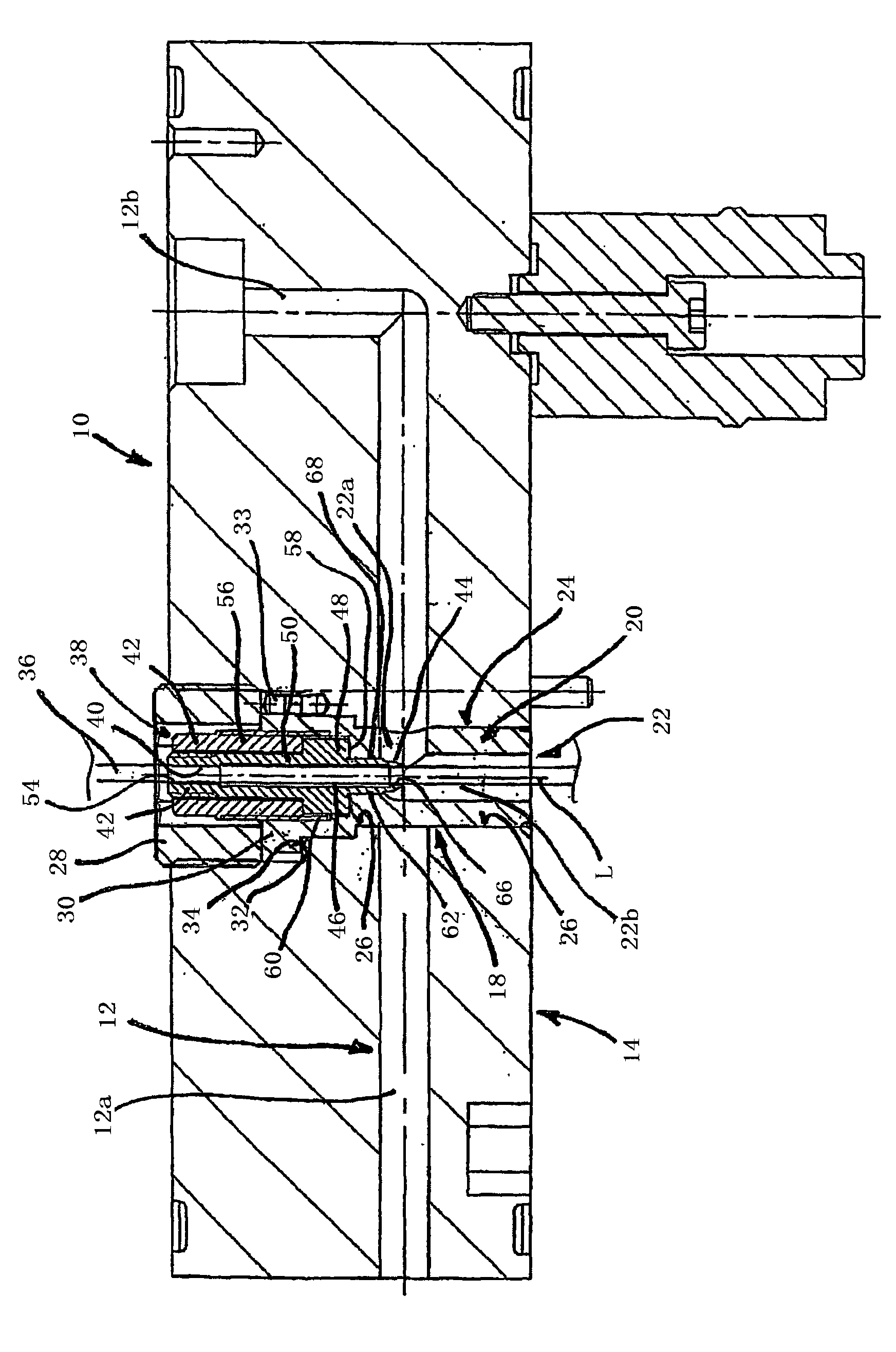

[0027] figure 1The hot runner distributor, generally designated by the reference numeral 10 , is part of an injection molding plant for producing molded parts from a flowable mass, for example a plastic melt. In the hot runner distributor 10, the fluid channel 12 is composed of a main fluid channel 12a and a secondary fluid channel 12b turning from the main fluid channel 12a. The fluid main channel 12 a and the fluid secondary channel 12 b are formed, for example, as bores in the hot runner distributor 10 . In order to divert the melt entering into the secondary fluid channel 12b and flowing through the main channel 12a in the downward direction, a plug 18 is inserted into a gap intersecting the secondary fluid channel 12a, which is formed as a through hole and is substantially vertical It extends in the extending direction of the main fluid channel 12a. The plug 18 now comprises a rotationally symmetrical sleeve 20, in which a channel 22 extending radially inwards from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com