Device for filtering solids from liquids

A liquid and material technology, applied in the field of devices for filtering out substances, can solve the problems of growth and premature decline of filtration efficiency, and achieve the effect of uniform filter residue growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

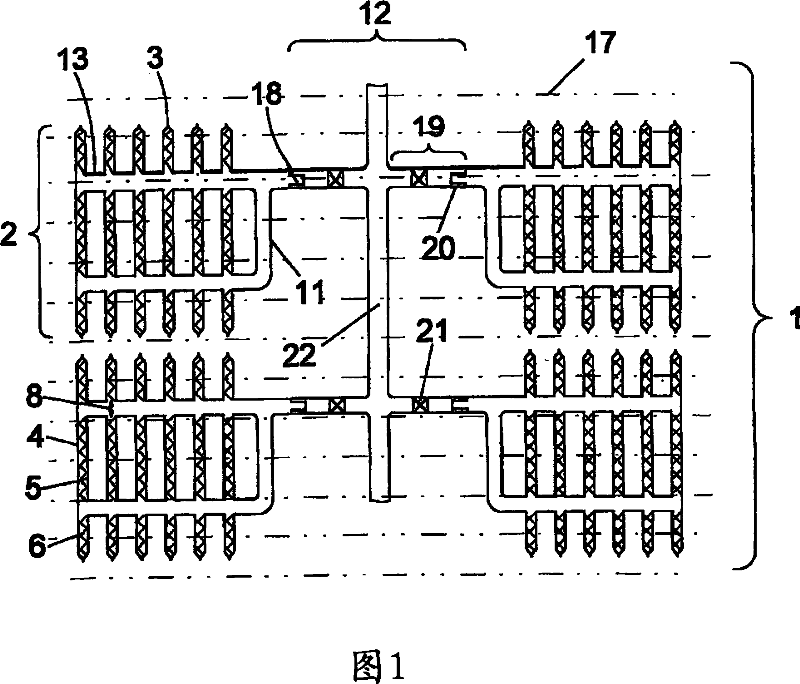

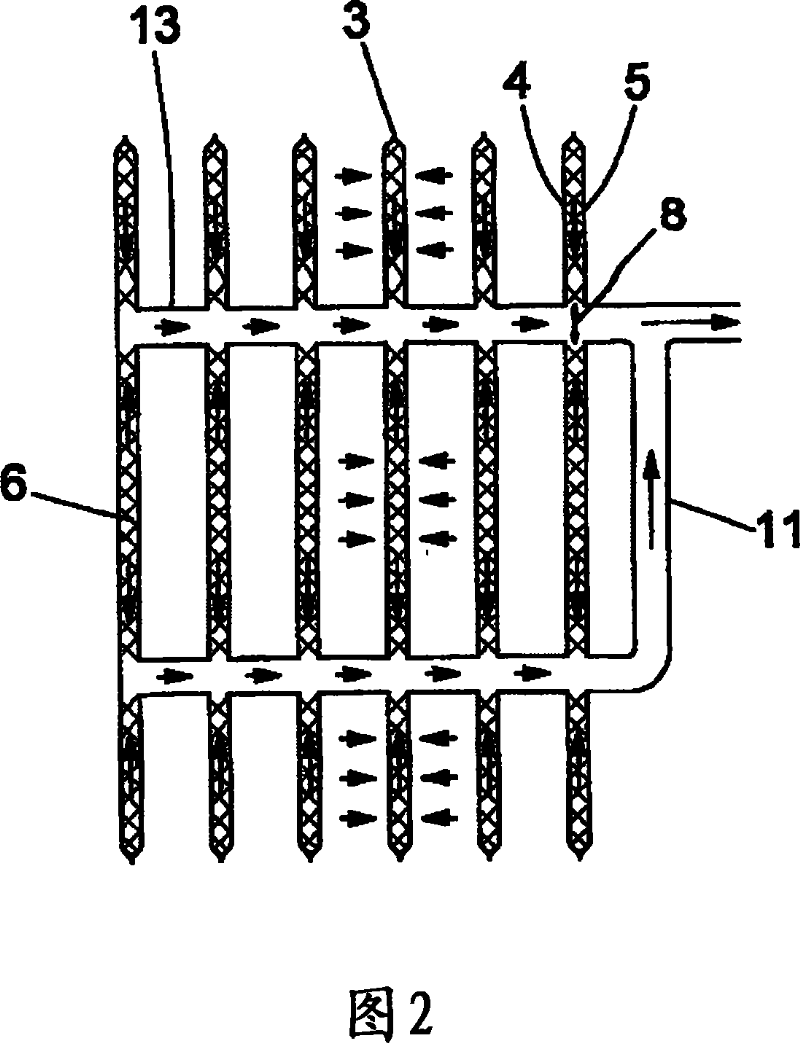

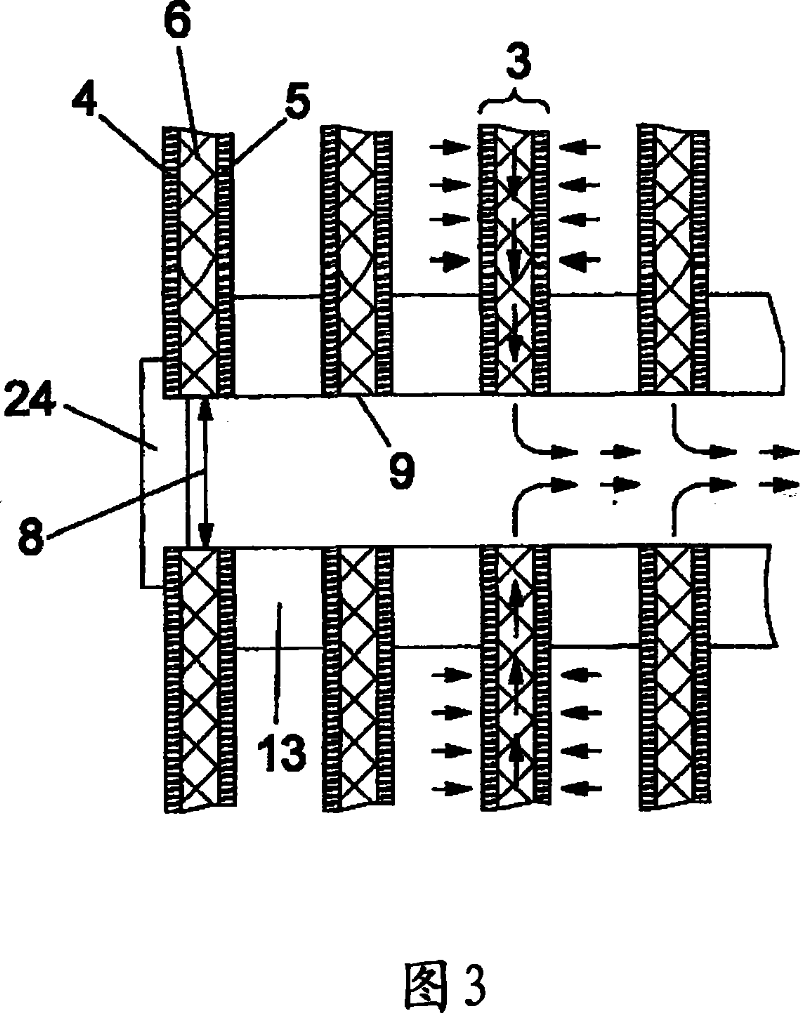

[0033]As can be seen from FIG. 1 , the device 1 consists of a plurality of filter modules 2 with filter elements 3 which are designed as flat film bags and which are surrounded or flow around by the liquid to be filtered. The filter elements 3 are arranged in parallel and at a certain distance from each other, and are pressure-tightly connected to each other by connecting elements 13, wherein the connecting elements 13 are connected to the output holes 8 on the filter elements 3, and the permeate outlets 11 of each filter module 2 are connected by means of a The connector 18 is connected to the permeate collector 12 . The permeate collector 12 includes a main conduit 22 from which a connection pipe 19 branches off. The connecting pipe 19 is equipped with a connector seat 20 and a valve 21 . In the connected state, the connector 18 and the connector seat 20 form a pressure-tight connection between the permeate outlet 11 and the permeate collector 12 .

[0034] The flow of per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com