A precision lifting type green and environmental protection building formwork

A kind of green environmental protection, building formwork technology, applied in the direction of building, building structure, formwork/formwork components, etc., can solve the problems of single limited angle of formwork support, unadjustable height, environmental pollution and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

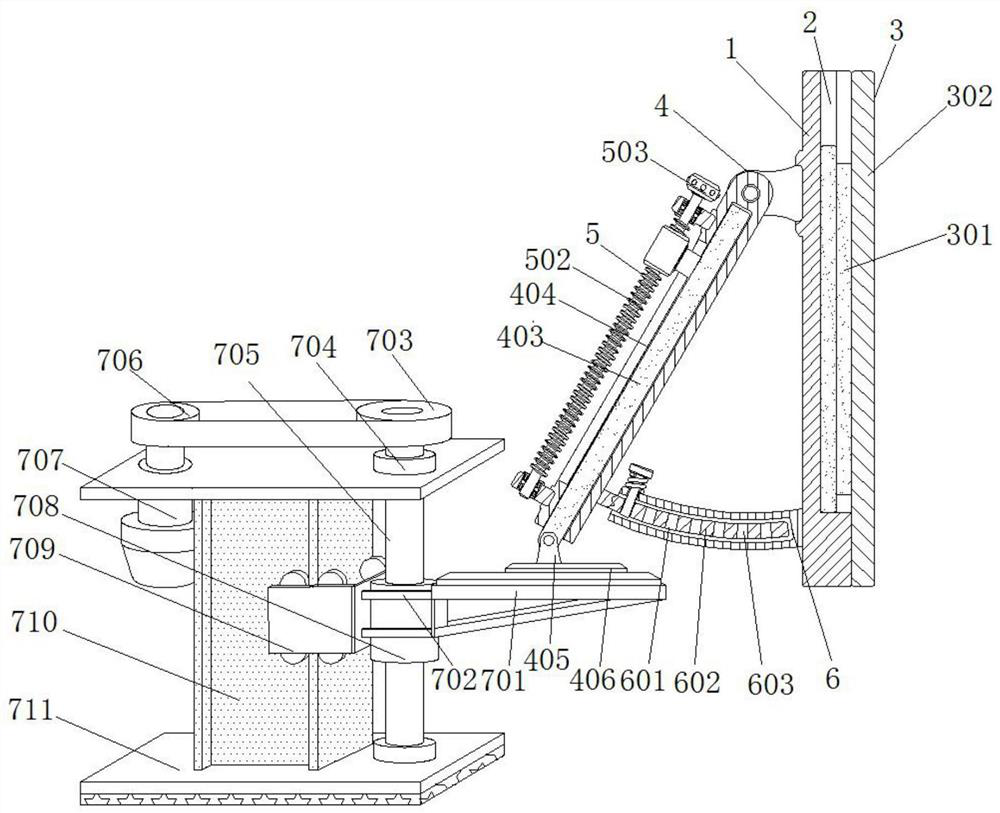

[0051] A precision lifting type green and environment-friendly building formwork, including a board body 1 and a lifting mechanism 7, and the lifting mechanism 7 includes a triangle connecting frame 701, a connecting rod 702, a large gear 703, a bearing 704, a screw rod 705, a pinion gear 706, and a motor 707 , axle sleeve 708, roller group 709, I-shaped plate 710 and backing plate 711; End rolling connection, the right side of roller group 709 is provided with triangular connecting frame 701, and connecting rod 702 is fixedly connected between the front and rear end of triangular connecting frame 701 left vertical plate and the front and rear ends of roller group 709 right vertical plate, There are four groups of connecting rods 702, and are evenly distributed on the upper and lower ends of the vertical plate on the left side of the triangular connection frame 701 and the upper and lower ends of the vertical plate on the right side of the roller group 709; A shaft sleeve 708 ...

Embodiment 2

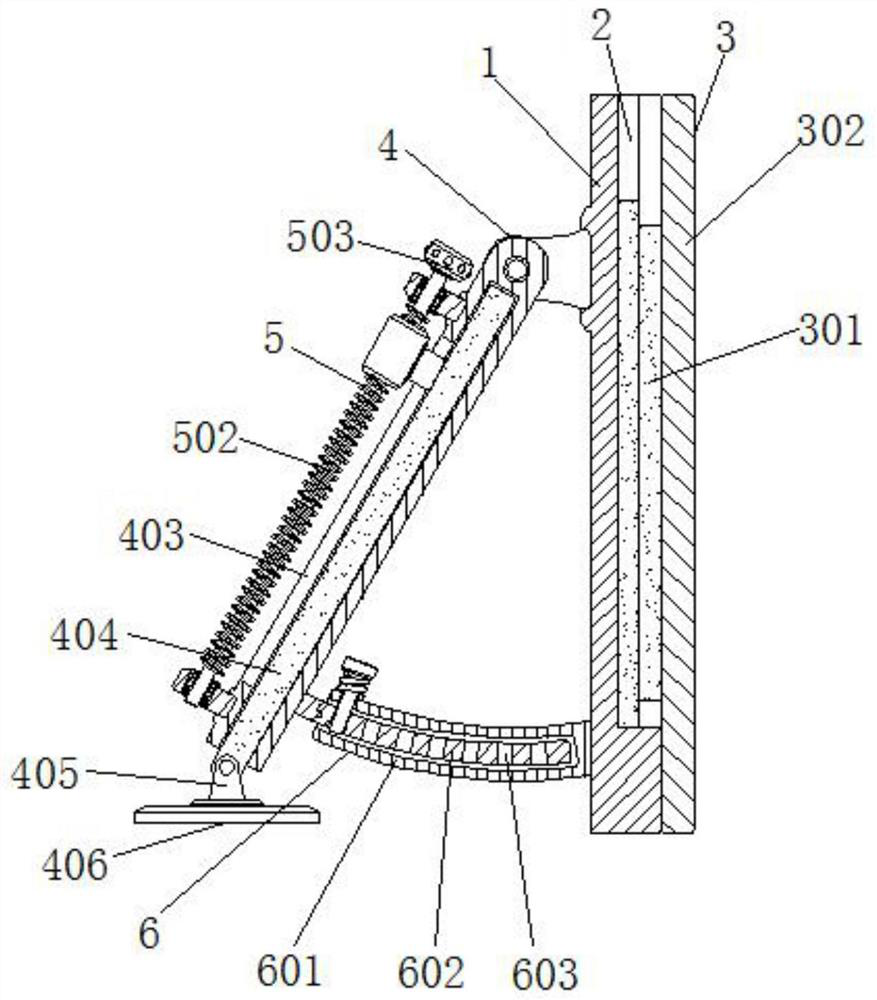

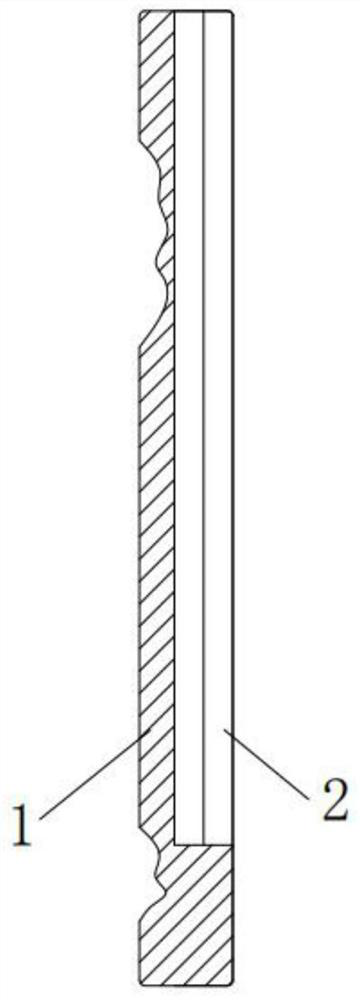

[0053] As an option, see figure 1 , 2 And 6, precision lifting type green and environmentally friendly building formwork, the right side of the board body 1 is processed with a T-shaped groove 2, and the right side of the board body 1 is provided with a contact mechanism 3, and the contact mechanism 3 includes formaldehyde-free zero-carbon waterproof and fire-resistant environmental protection board 301 And the T-shaped block 302, the aldehyde-free zero-carbon waterproof, fire-proof and environmentally friendly plate 301 is attached to the right side of the board body 1, and the aldehyde-free and zero-carbon waterproof, fire-proof and environmentally friendly plate 301 has anti-deformation, anti-expansion, anti-mildew, anti-corrosion, acid and alkali resistance, Anti-bending, anti-warping, anti-cracking and environmental protection, formaldehyde-free, odorless, renewable and recyclable resources, formaldehyde-free, zero-carbon, waterproof, fire-proof and environmentally friend...

Embodiment 3

[0056] As an option, see figure 1 , 2 , 6 and 7, precision lift-type green building formwork, the left side of the plate body 1 is provided with a support mechanism 4, the support mechanism 4 includes a first connecting shaft 401, a first rod body 402, a through groove 403, a second rod body 404, The second connecting shaft 405 and the horizontal plate 406, the first rod body 402 is connected to the left side of the plate body 1 through the first connecting shaft 401, the left side of the inner wall of the first rod body 402 is processed with a through groove 403, the inner wall of the first rod body 402 The second rod body 404 is fitted with clearance, so that the second rod body 404 can carry out lifting movement on the inner wall of the first rod body 402, and the bottom of the second rod body 404 is connected with the horizontal plate 406 through the second connecting shaft 405, and the bottom of the horizontal plate 406 is connected with the horizontal plate 406. The tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com