Auxiliary structure of wind generating set tower

A technology for wind turbines and auxiliary structures, which is applied in the monitoring of wind turbines, wind turbines, installation/support configuration of wind turbines, etc. It can solve the problems of unfavorable refrigerant equipment heat dissipation, large volume, high temperature, etc., to reduce sunlight radiation and The impact of waves on the tower, the effect of enhancing wind load resistance and reducing maintenance times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It should be noted that the orientation words "up, down, horizontal, vertical" in this article refer to figure 1 The up, down, horizontal and vertical directions in the middle. The location words appearing in this article are all established on the basis of the habitual usage of those skilled in the art and the drawings in the specification, and their appearance should not affect the protection scope of the present invention.

[0026] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

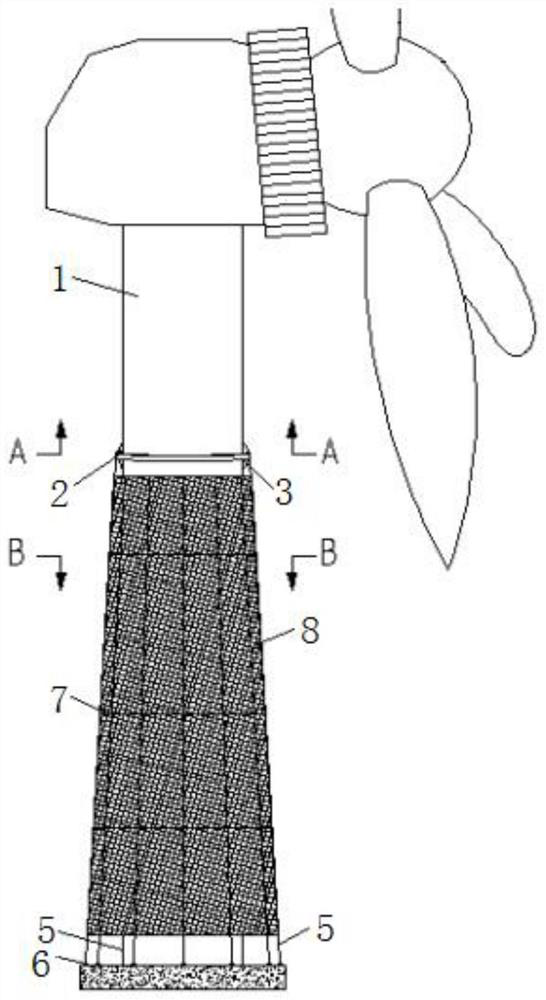

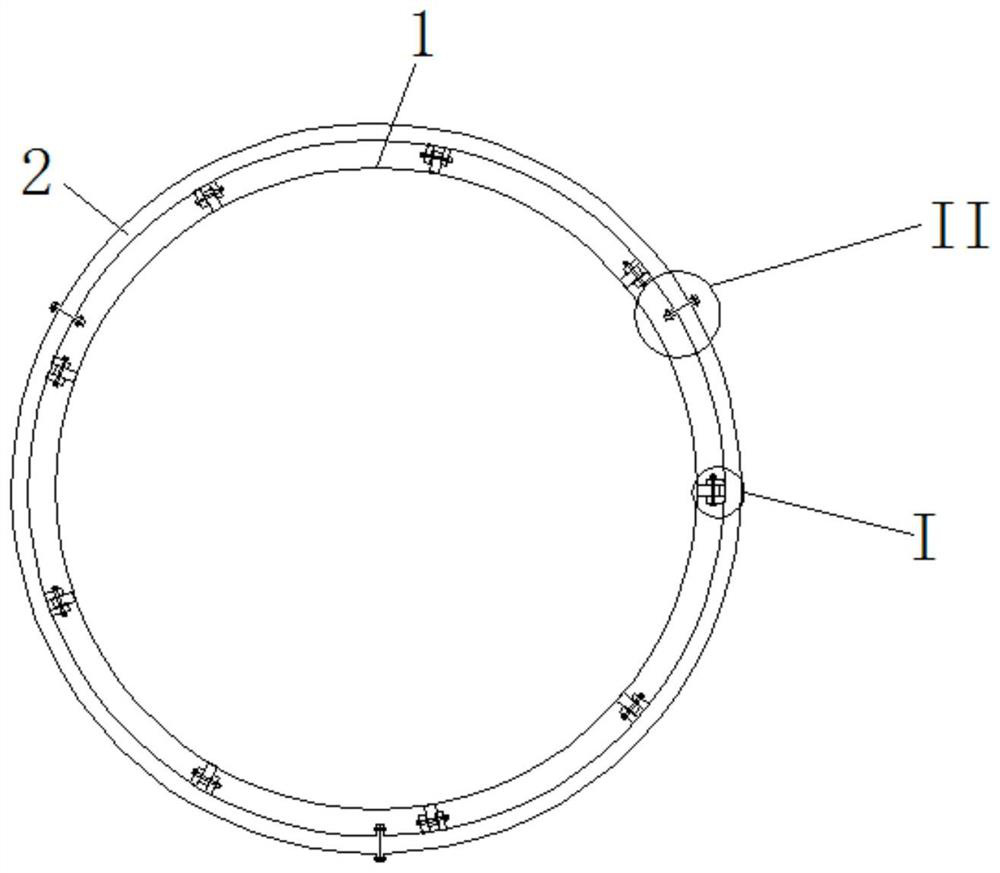

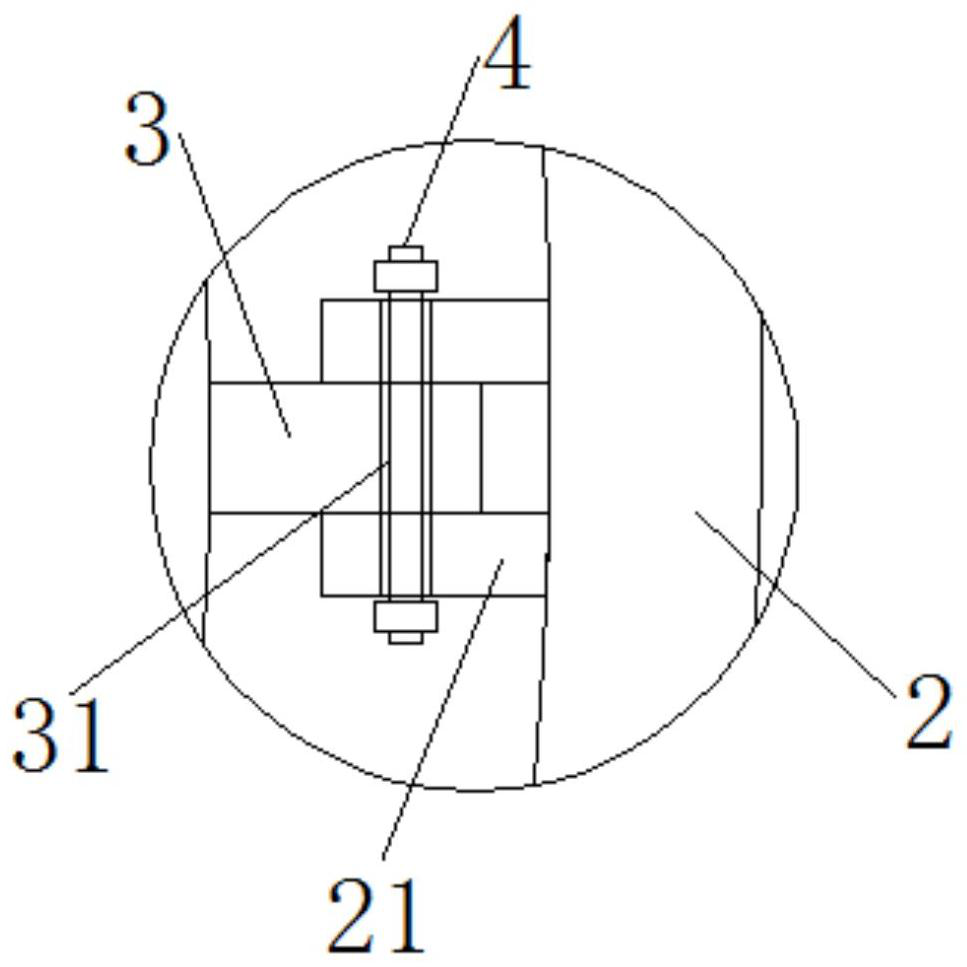

[0027] Please refer to Figure 1 to Figure 9 , figure 1 It is a schematic diagram of the auxiliary structure of the wind turbine tower provided by the present invention; figure 2 for figure 1 Sectional view of A-A; image 3 for figure 2 Enlarged view of middle I; Figure 4 for figure 2 Enlarged view of mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com