An anti-loose connection pipeline fastener

A technology for connecting pipes and fasteners, which is applied in the direction of pipes/pipe joints/fittings, pipe elements, sleeves/sockets, etc., which can solve the problems of inability to effectively resist external water spray, poor sealing effect, and pipeline detachment and other problems, to achieve good fixing effect, reduce loosening problems, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

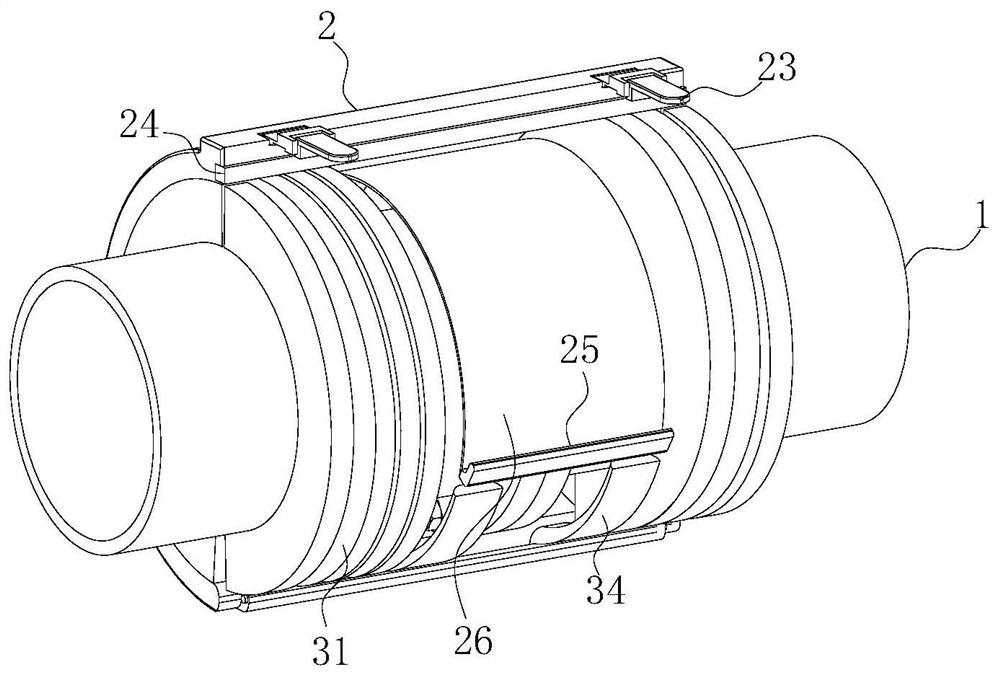

[0033] As an embodiment of the present invention, the inner arc surfaces of the fixed lock housing 21 and the rotating lock housing 2 are provided with card slots below the axis of the pipeline 1; Block 25; the same sealing film 26 is fixedly connected between the two blocks 25. When the fastener is fixed on the surface of the pipeline 1, the sealing film 26 is stretched to a position close to the sealing strip 24, and the sealing film 26 is located at the leaking position. Location;

[0034] During work, by setting the clamping block 25 and the sealing film 26, the two clamping blocks 25 are engaged with the fixed lock housing 21 and the rotating lock housing 2 respectively, and at the same time, the sealing film 26 is fixed between the two clamping blocks 25, when When the fixed lock housing 21 and the rotating lock housing 2 are engaged, the sealing film 26 can be directly located in the leakage area of the pipeline 1, and because the sealing film 26 has an elastic effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com