Metering calibration device

A technology of calibration device and calibration block, which is applied in the direction of measurement device, force/torque/work measuring instrument calibration/test, instrument, etc. , Simple structure, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

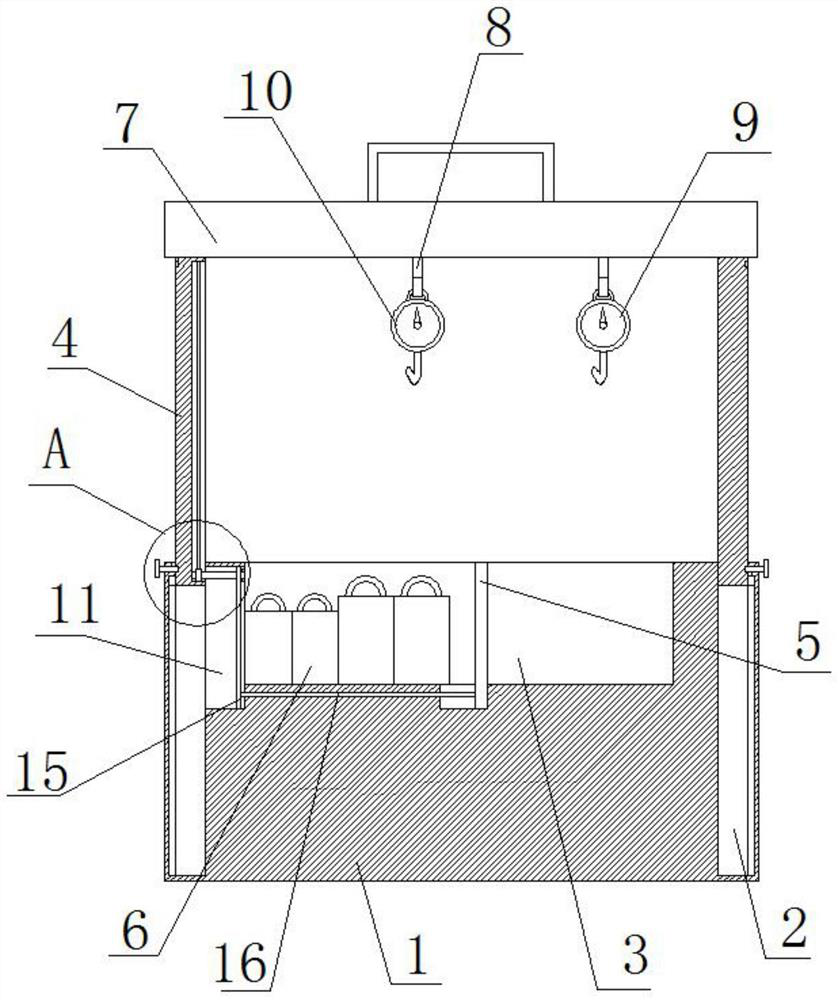

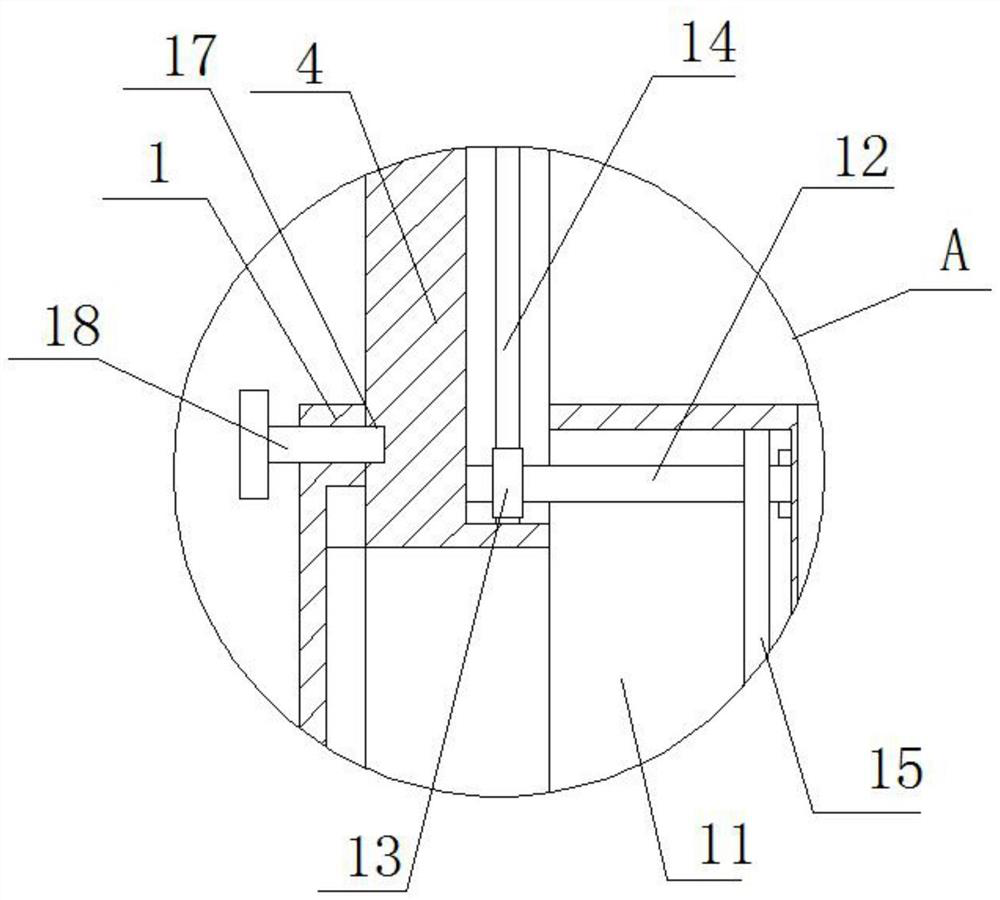

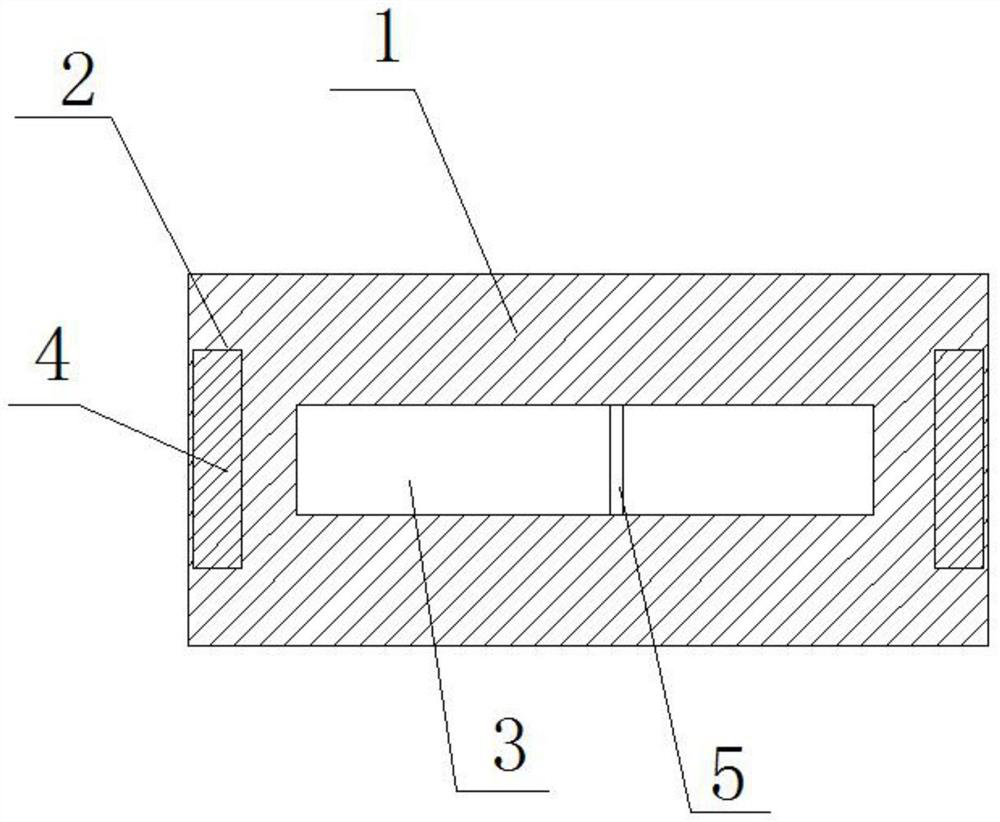

[0020] refer to Figure 1-3 , a measurement and calibration device, including a mounting base 1, the top of the mounting base 1 is provided with two slide grooves 2 and a placement groove 3, two sets of calibration blocks 6 are placed in the placement groove 3, and the top of the calibration block 6 is fixedly connected with Hanging ring, the lifting plate 4 is slidingly installed in the two chute 2, the same cover plate 7 is fixedly installed on the top of the two lifting plates 4, the top of the cover plate 7 is fixedly installed with a handle, and the bottom of the cover plate 7 is fixedly installed There are two fixed hooks 8, on which the dynamometer 9 to be calibrated and the standard dynamometer 10 are hung respectively, and two thread grooves 17 are provided on the sides of the two lifting plates 4 that are far away from each other, and the mounting base 1 Bolts 18 are threadedly installed on both sides of the body, and two bolts 18 are threadedly connected with corres...

Embodiment 2

[0026] refer to Figure 1-3 , a measurement and calibration device, including a mounting base 1, the top of the mounting base 1 is provided with two slide grooves 2 and a placement groove 3, two sets of calibration blocks 6 are placed in the placement groove 3, and the top of the calibration block 6 is fixedly connected with Hanging ring, the lifting plate 4 is slidably installed in the two chute 2, the top of the two lifting plates 4 is fixedly installed with the same cover plate 7 by welding, the top of the cover plate 7 is fixedly installed with a handle by welding, the cover plate 7 Two fixed hooks 8 are fixedly installed on the bottom by welding, and the dynamometer 9 to be calibrated and the standard dynamometer 10 are respectively hung on the two fixed hooks 8, and two screw threads are provided on the sides of the two lifting plates 4 that are far away from each other. Bolts 18 are threadedly installed on both sides of the mounting base 1 , and two bolts 18 are threade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com