High-speed switch

A high-speed switch and static contact technology, applied in the direction of electric switches, high-voltage/high-current switches, high-voltage air circuit breakers, etc., can solve the problem of slow response speed of opening and achieve the effect of fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

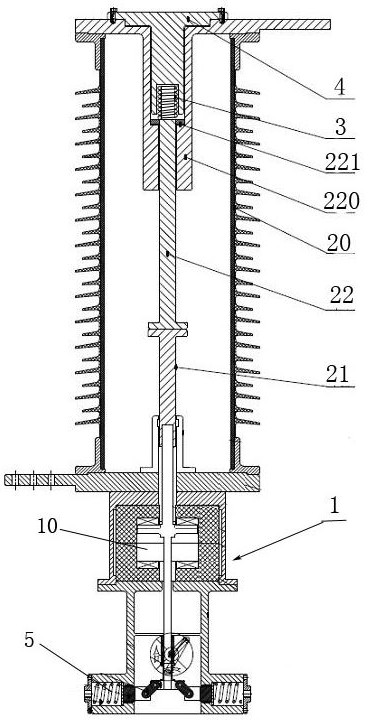

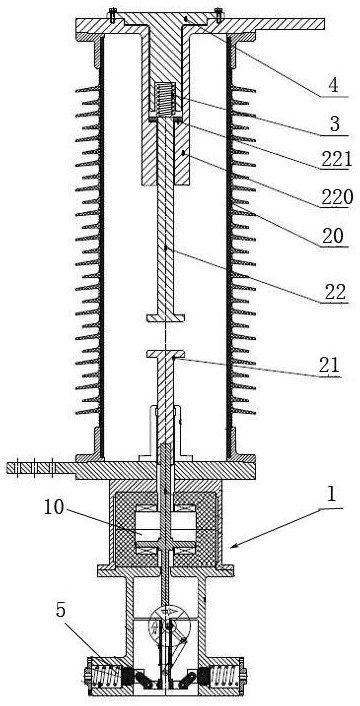

[0031] The high-speed switch of the present invention such as Figure 1-2As shown, it includes the operating unit 1 and the fracture structure. For ease of description, the following description will only be made in the directions shown in the figure, without limiting the actual directions of the components of the high-speed switch during use. Wherein, the fracture structure includes an insulating sleeve 20, and the upper and lower ends of the insulating sleeve 20 are respectively sealed with terminal blocks. A moving contact assembly and a static contact assembly are relatively installed in the insulating sleeve 20. The moving contact assembly includes a moving contact seat fixedly installed on the lower wiring seat and a moving contact 21 guided and slidably installed in the moving contact seat. The head 21 realizes the conduction with the lower wire seat through conductive contact with the movable contact seat. The static contact assembly includes a static contact seat 22...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap