Large storage tank vault beam welding assembly platform

A vault beam and platform technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of poor versatility, waste of construction auxiliary materials and human resources, occupation of construction sites, etc., to reduce demand, Labor cost saving and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

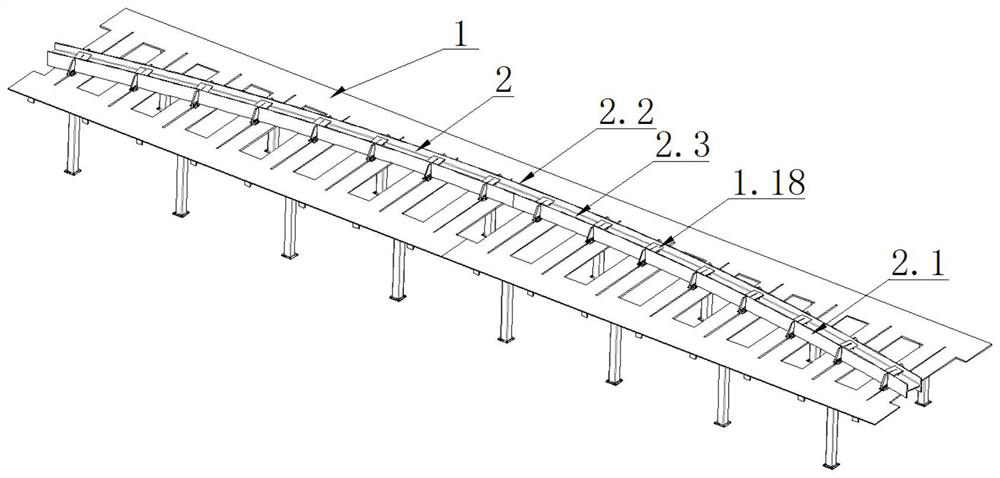

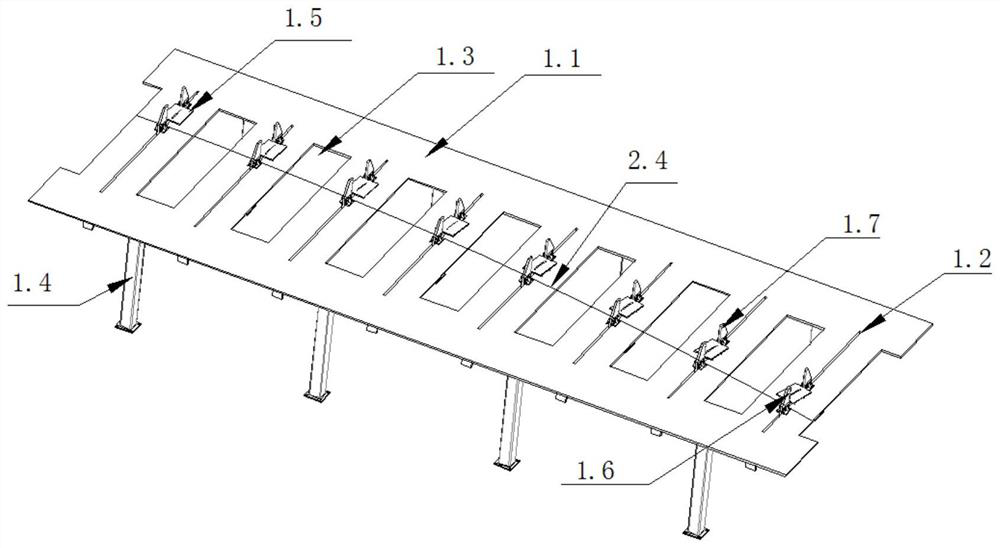

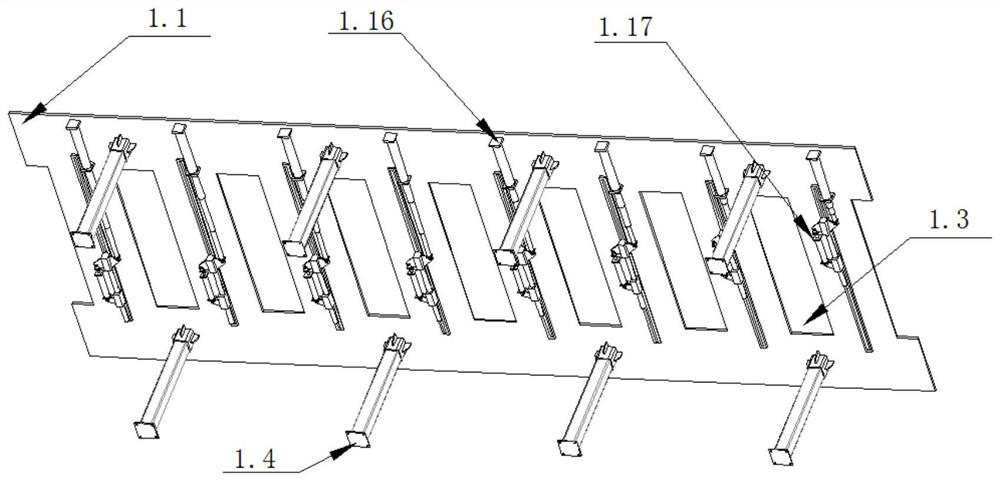

[0023] The vault beam 2 of the storage tank is mostly an "H" steel curved structure, which includes the web 2.3 and the inner and outer flange plates on both sides of the web 2.3; the web 2.3 and the two flange plates are cut by steel plates, and finally assembled and welded to form an arch Top beam 2. Such as figure 1 Shown is a large storage tank arch beam 2 welded pair platform 1, the pair platform 1 is spliced by several platform units in sequence, each platform unit includes a platform base 1.1 and a plurality of fixed arch beams 2. The clamping components of the inner and outer flange plates, each clamping component is arranged at intervals along the length direction of the platform base 1.1; each set of clamping components is equipped with a driving device, and the driving device dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com