A collection device suitable for the production of melt-blown cloth

A collection device and technology of melt-blown cloth, applied in cleaning methods using tools, non-woven fabrics, plastic recycling, etc., can solve problems such as stagnation, low collection effect, equipment congestion, etc., to improve cleaning effect and expand contact The effect of large area and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

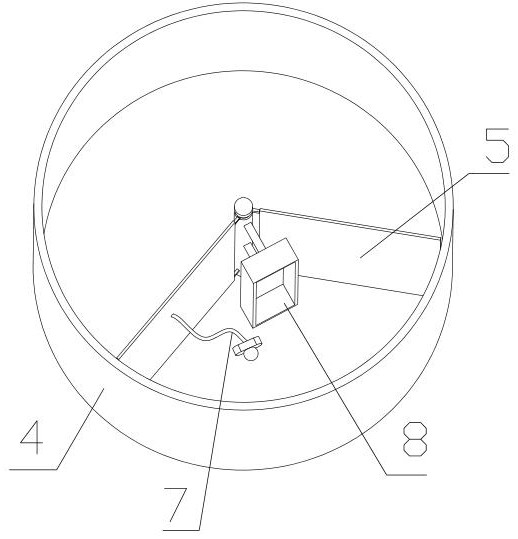

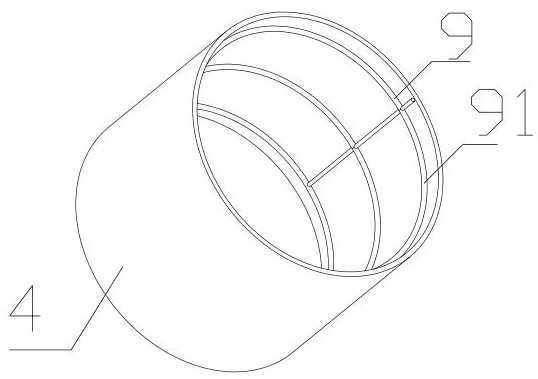

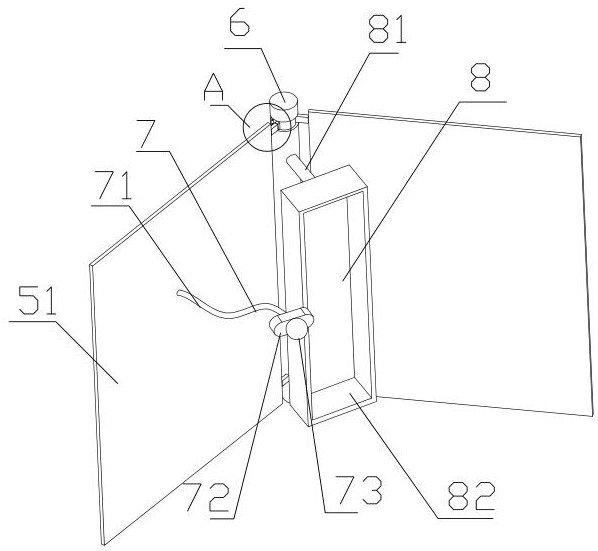

[0039] Example one, as figure 1 As shown, a collection device suitable for the production of meltblown cloth, its main collection component is not the plate-shaped collection panel in the traditional technology, but adopts the collection cylinder 4, and the collection cylinder 4 is continuously under the action of the driving device. The driving device can use the rotating drum in the prior art, and the rotating drum collides with the surface of the collecting drum 4 to transmit power.

[0040] Several extruders (not shown in the figure) can be arranged at the outer position of the collecting cylinder 4, and the extruder is provided with a melt-blown head, and the melt-blown head uses high-speed hot air to draw the thin stream of molten polymer, thereby forming The microfibers are aggregated on the outer surface of the collecting drum 4 and form a cloth by self-bonding.

[0041] The collection drum 4 is constantly rotating, which is equivalent to the collection panel of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com