Collecting device suitable for melt-blown cloth production

A technology of collecting device and melt-blown cloth, which is applied to cleaning methods using tools, non-woven fabrics, plastic recycling, etc., can solve the problems of stagnation, low collection effect, equipment congestion, etc., to expand the touch area and improve cleaning. Effects, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

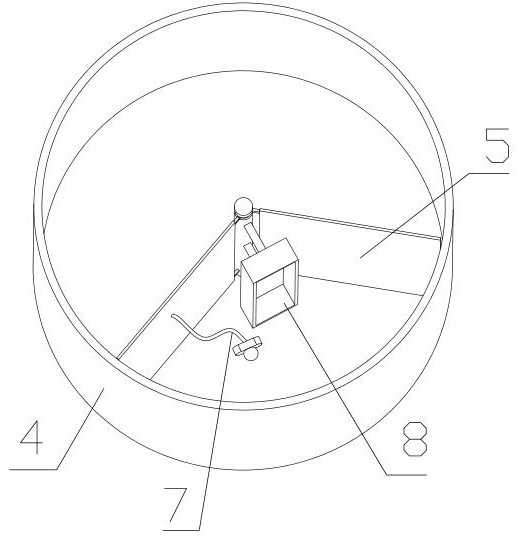

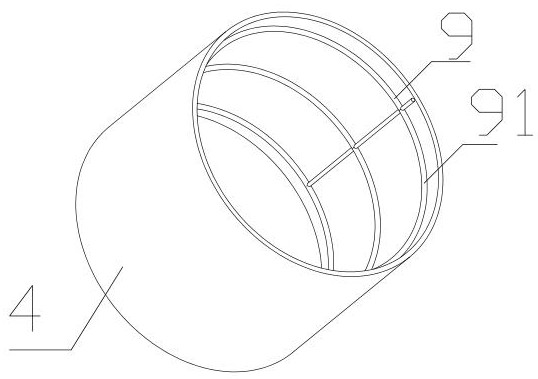

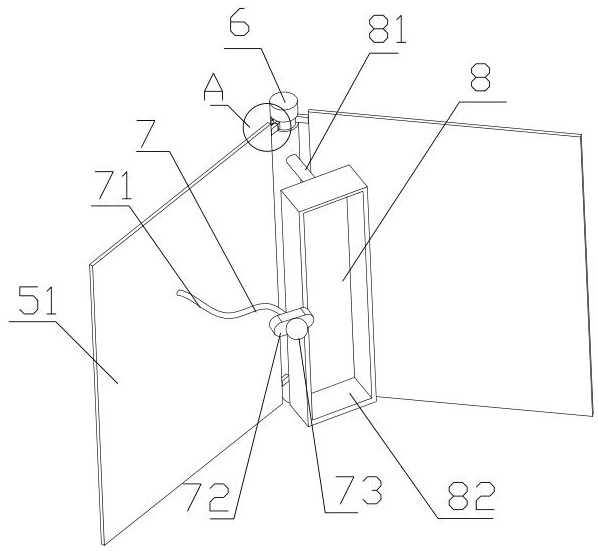

[0039] Embodiment one, such as figure 1 As shown, a collection device suitable for the production of melt-blown cloth, its main collection part is not a plate-shaped collection panel in the traditional technology, but a collection tube 4 is used, and the collection tube 4 is constantly under the action of the driving device. The rotating drum of the prior art can be used as the driving device, and the rotating drum conflicts with the surface of the collecting drum 4 to transmit power.

[0040] Several extruders (not shown in the figure) can be arranged on the outer side of the collecting tube 4, and the extruder is provided with a melt blown head, which uses high-speed hot air to draw the molten polymer stream, thus forming The superfine fibers are also condensed on the outer surface of the collecting tube 4, and form cloth by self-bonding.

[0041] The collecting cylinder 4 is constantly rotating, and compared to the collecting panel in the prior art, the temperature uniform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com