Channel external type distributor anode integrated structure for low-power hall thruster

A Hall thruster, external technology, applied in the direction of thrust reverser, plasma utilization, machine/engine, etc., can solve the problems of thruster outer contour size, weight increase, high cost, etc., to achieve simple structure, good market prospect, Good scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Such as Figure 2-8 Shown, the present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

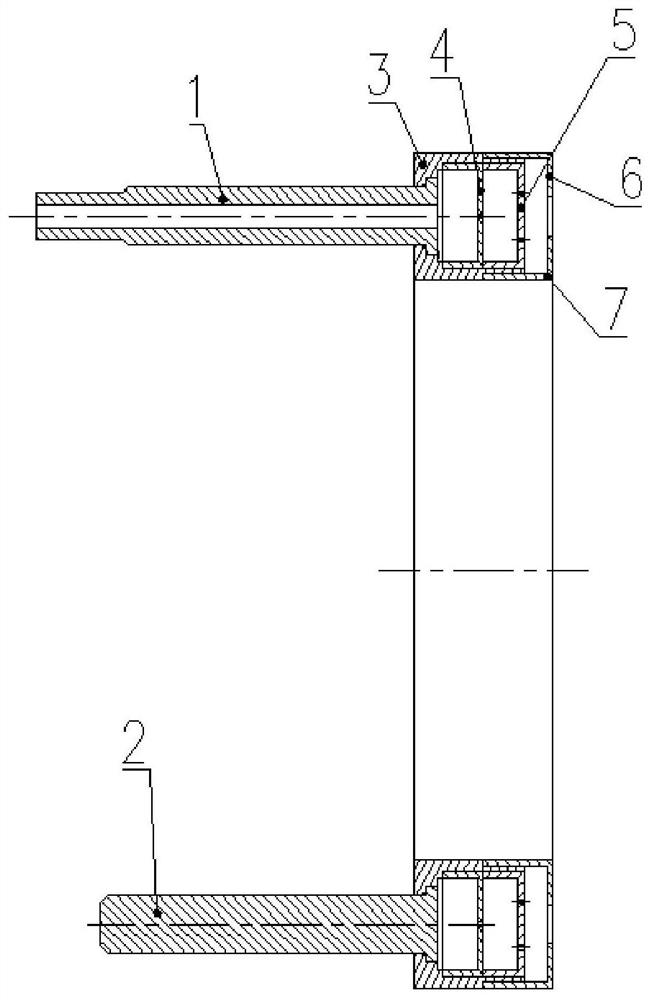

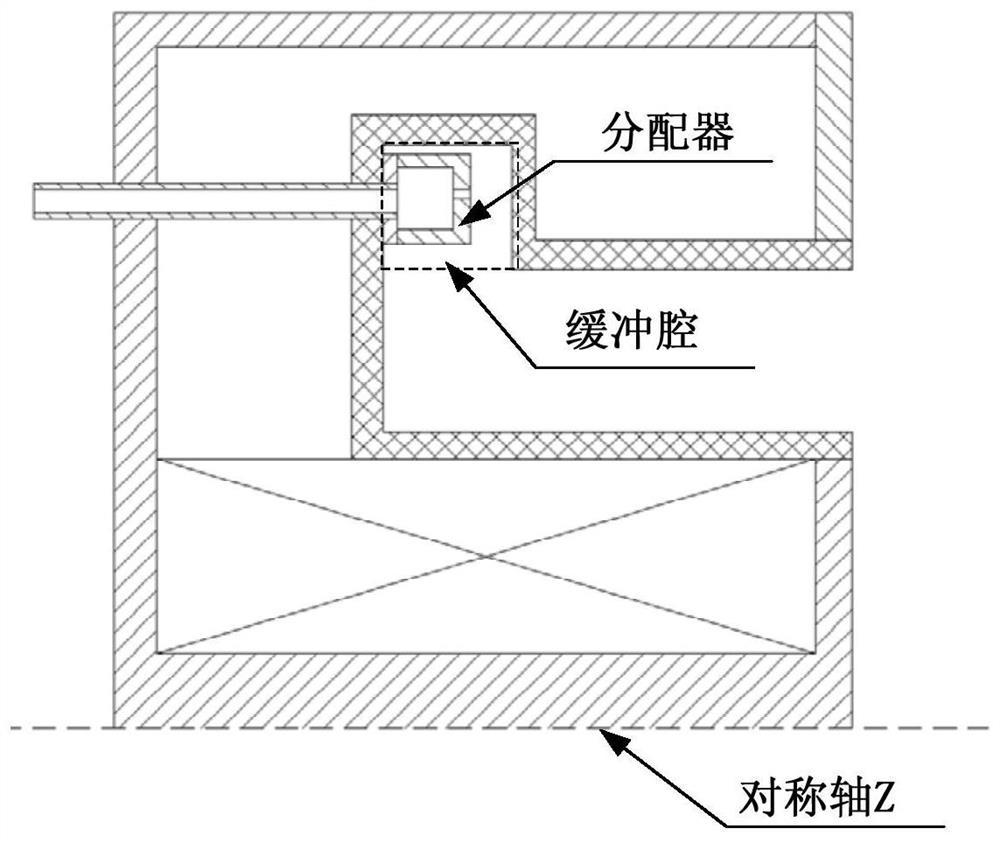

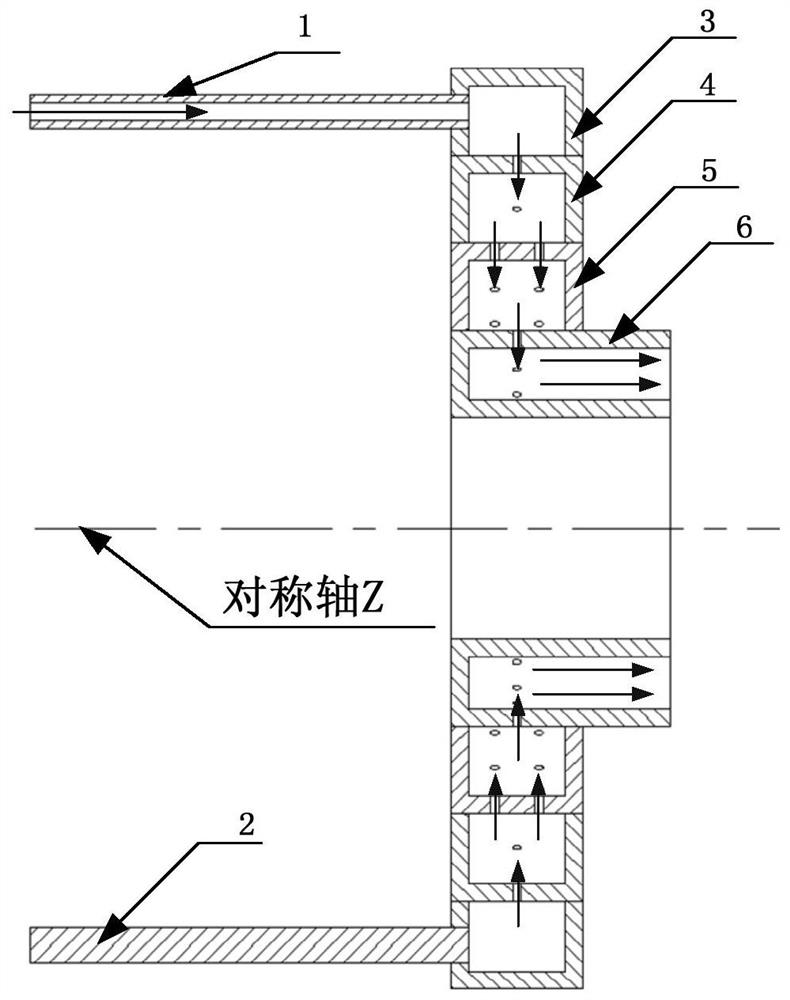

[0029] An integrated anode structure of an external distributor for a Hall thruster, such as image 3 As shown, it includes an air guide column 1, a fixed column 2, an air intake chamber 3, a single row of hole chamber 4, a double row of hole chamber 5, and a channel chamber 6; the air guide column 1 inserted into the air intake chamber 3 Through holes, the gas guide column 1 is stably connected to the air intake chamber 3 by electron beam welding; the fixed column 2 is inserted into the through hole in the air intake chamber 3, and the fixed column 2 is connected to the air intake chamber by electron beam welding. The chamber 3 is stably connected; the single-row hole chamber 4 is inserted into the air intake chamber 3, and the air inlet chamber 3 and the single-row hole chamber 4 are stably connected by elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com