Actuator for hydraulic valve and hydraulic valve

A technology for actuators and hydraulic valves, applied in the field of hydraulic valves and actuators, can solve problems such as leakage of lateral force, improvement, and adverse effects on adjustment quality, and achieve the effect of simple cost and saving coating consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

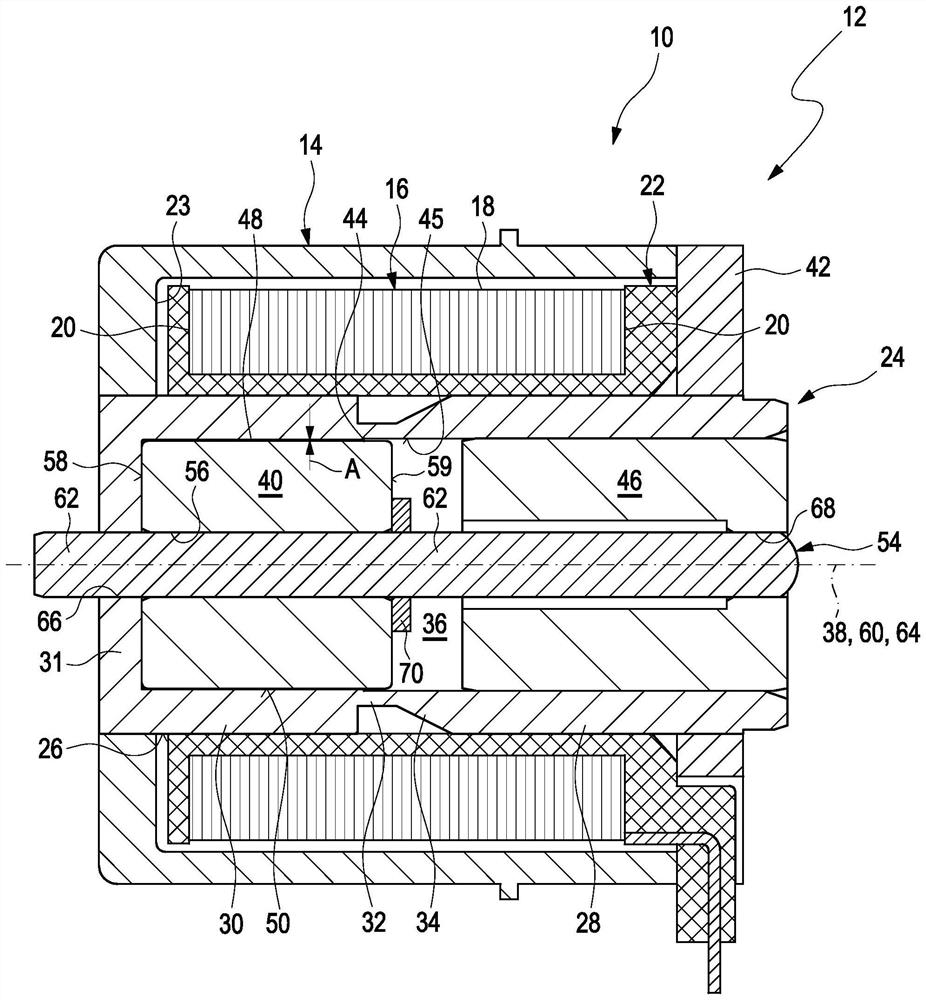

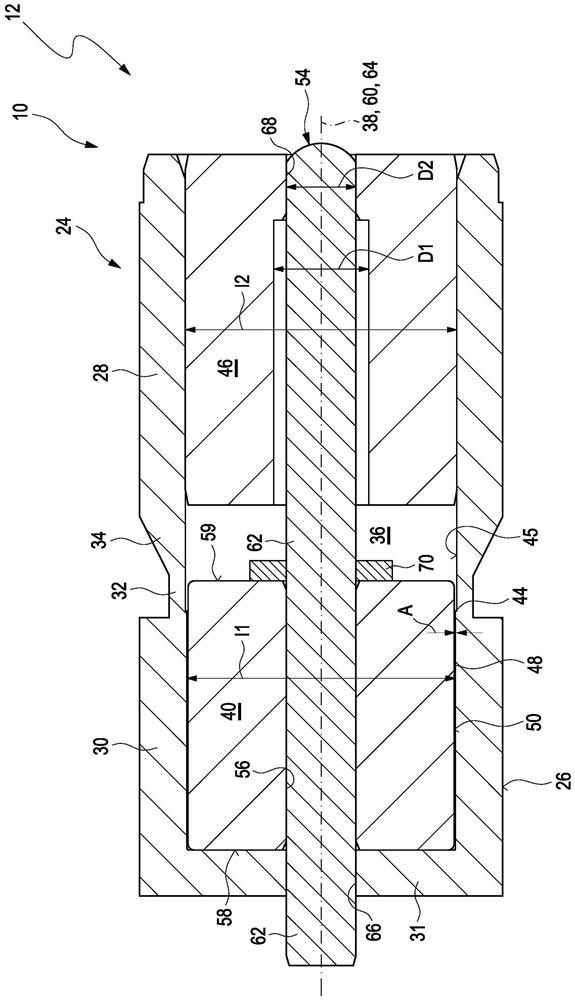

[0028] In the figures, the same or the same type of parts are denoted by the same reference numerals. The drawings show examples only and are not to be construed as limiting.

[0029] exist figure 1 The actuator 10 according to the invention of the hydraulic valve 12 according to the invention is shown in longitudinal section. Starting from the actuator 10, the hydraulic valve 12, which is not shown in detail among the components configured for hydraulic functions, also includes a control valve with a housing with hydraulic connections, the housing has An axially movable hydraulically permeable piston is accommodated axially displaceably in order to release and close a throughflow opening formed in the housing. The piston is positioned axially by means of the actuator 10 .

[0030]The actuator 10 comprises a magnetizable actuator housing 14 which surrounds the magnetic coil 16 on its outer circumference 18 and on at least one end face 20 of the magnetic coil. For reasons o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com