Method for measuring number of holes of polyurethane sponge

A technology of polyurethane sponge and measurement method, which is applied in the field of polyurethane filter materials for automobile carbon canisters, can solve the problems of no industry unified standards, primitive means, vague concepts, etc., improve detection efficiency and accuracy, and facilitate promotion and communication , the effect of a clear concept

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

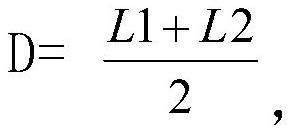

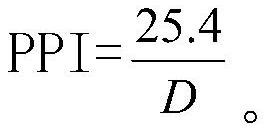

[0031] For the polyurethane sponge model HD-CF3320B-80, the diameter L1 of the transverse cell is 621.8mm and the diameter of the longitudinal cell is 594.2mm when the complete hole is measured by a microscope. The calculation formula for the diameter of a single cell diameter is 608mm. Finally, the PPI is 41.78PCS / IN through the calculation formula of the number of polyurethane sponge cells.

Embodiment 2

[0033] For the polyurethane sponge model HD-CF336.6W-80, the diameter L1 of the transverse cell is 591.0mm and the diameter of the longitudinal cell is 560.3mm measured by a microscope for the complete hole. The calculation formula for the diameter of a single pore diameter is D as 575.65mm. Finally, the PPI is 44.12PCS / IN through the calculation formula of the number of polyurethane sponge cells.

Embodiment 3

[0035] For the polyurethane sponge model HD-CF3312Y-80, the diameter L1 of the transverse cell is 603.8mm and the diameter of the longitudinal cell is 572.6mm when the complete hole is measured by a microscope. The calculation formula for the diameter of a single cell diameter is 588.2mm. , Finally, the PPI is 43.18PCS / IN through the calculation formula of the number of polyurethane sponge cells.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com