Rock multi-unit non-uniform uniaxial loading creep experiment device and working method

An experimental device, multi-unit technology, applied in the direction of measuring device, using stable tension/pressure test material strength, instrument, etc., can solve the problem of not considering rock anisotropy, lack of rock mechanics experimental method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below with reference to the drawings and embodiments, but the protection scope of the present invention is not limited by the drawings and embodiments.

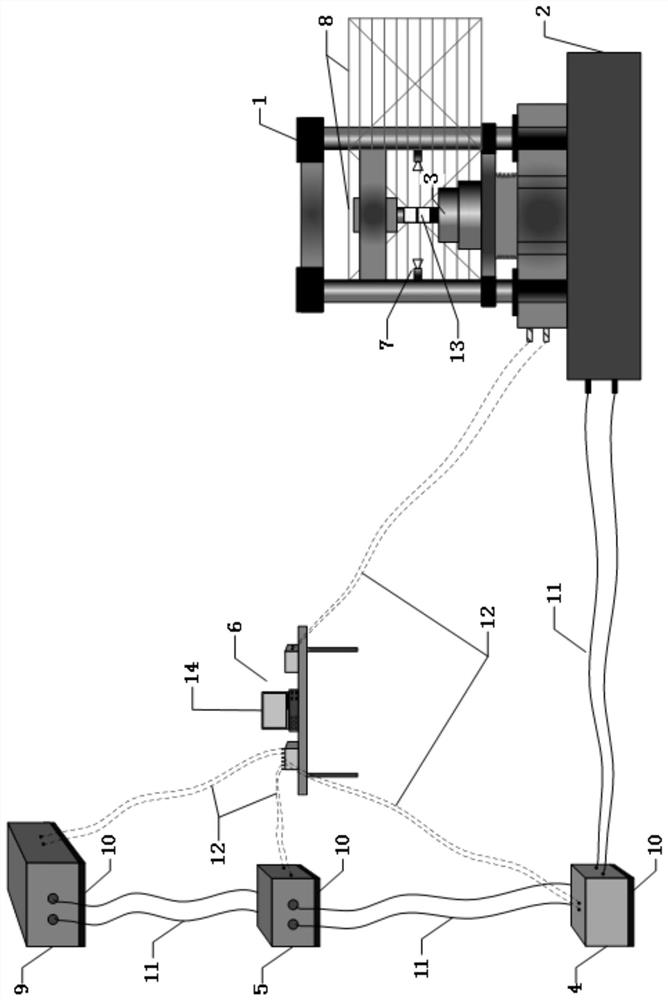

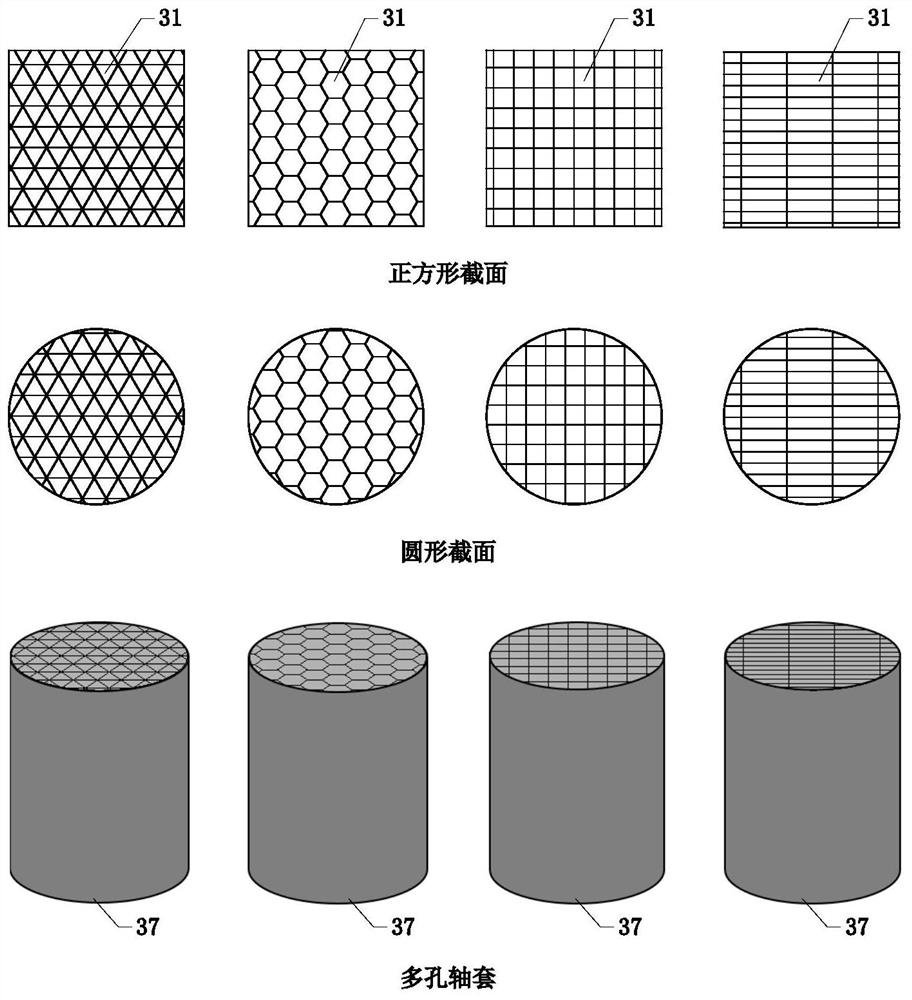

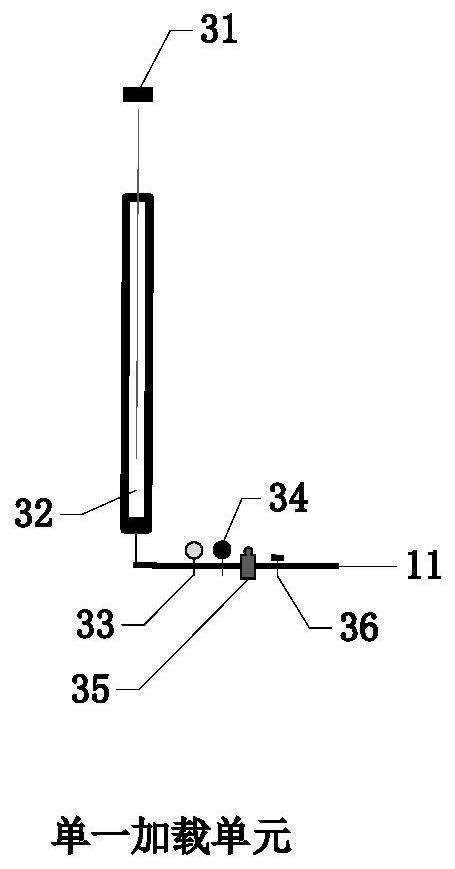

[0039] figure 1 It is a structural schematic diagram of the rock multi-unit non-uniform uniaxial loading creep experiment device of the present invention, figure 2 It is a schematic diagram of the structure of the multi-unit axial pressure loading module of the experimental device of the present invention. image 3 It is a schematic diagram of the single loading unit structure of the experimental device unit axial pressure loading module of the present invention, Figure 4 Be the stressed schematic diagram of specimen in the embodiment (when uniaxial loading creep experiment), Figure 5 It is a schematic diagram of Weibull distribution under different parameter conditions in the embodiment (during uniaxial loading creep experiment). as the picture shows:

[0040] A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Stiffness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com