Patents

Literature

31results about How to "Eliminate static friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

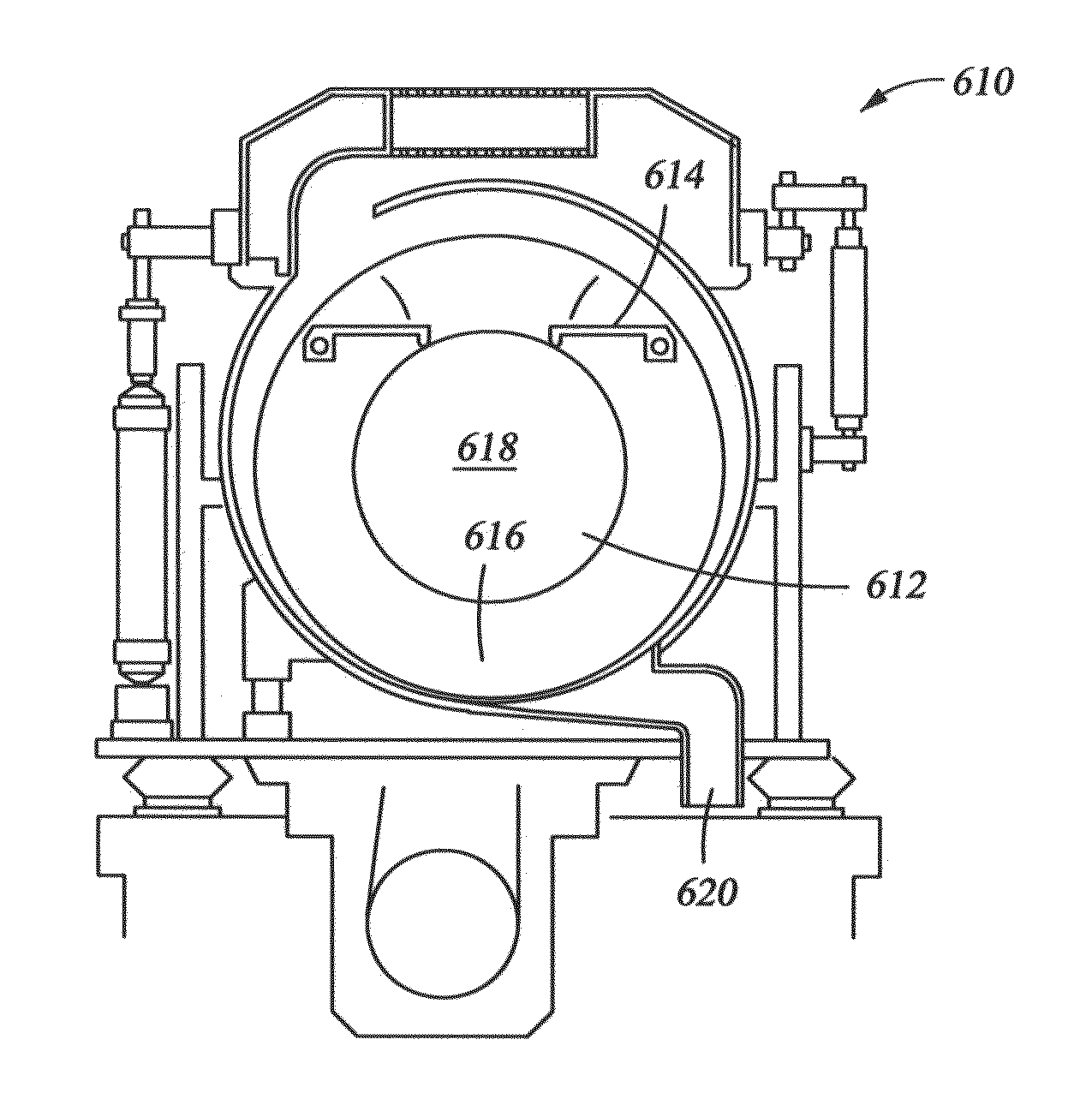

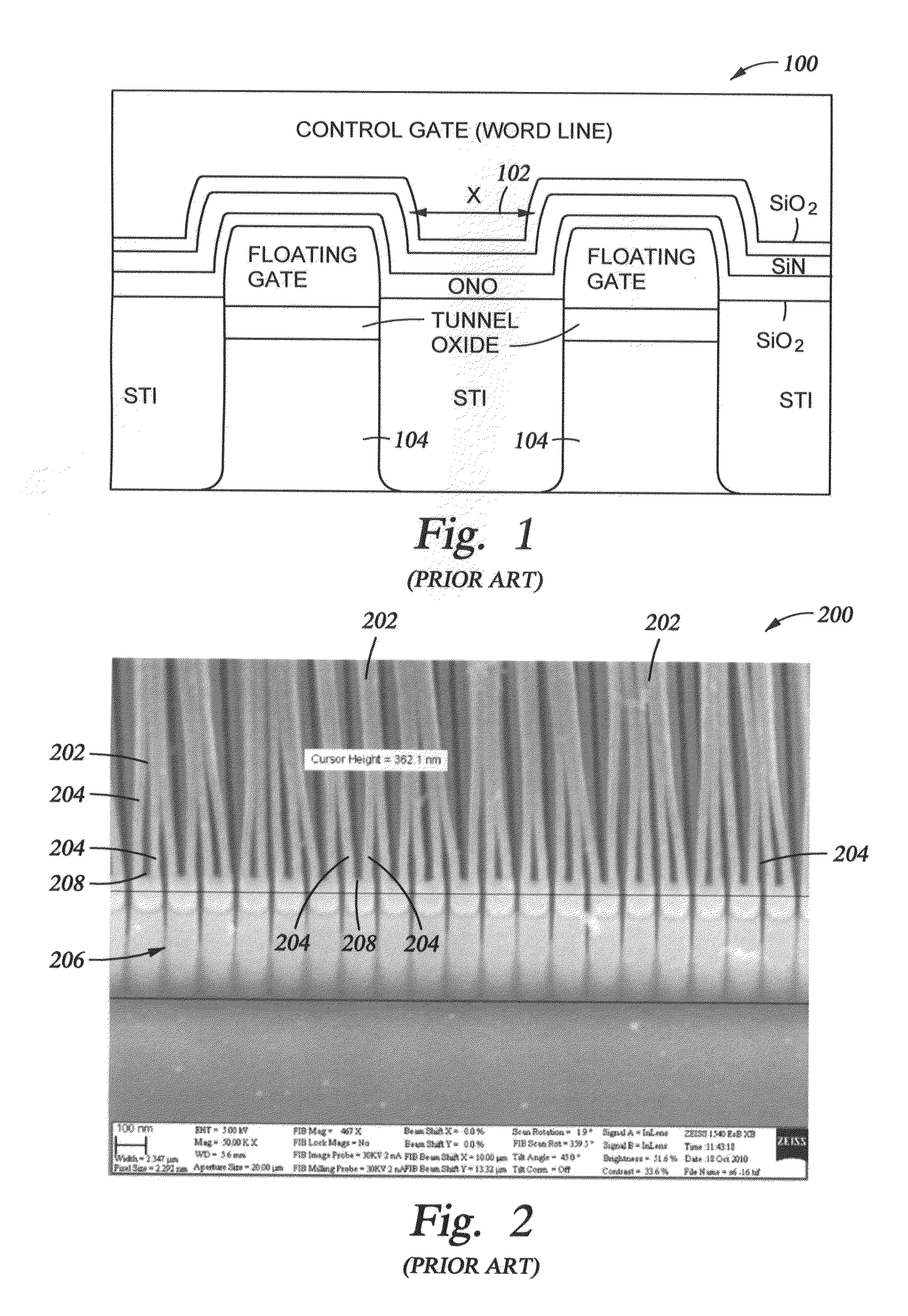

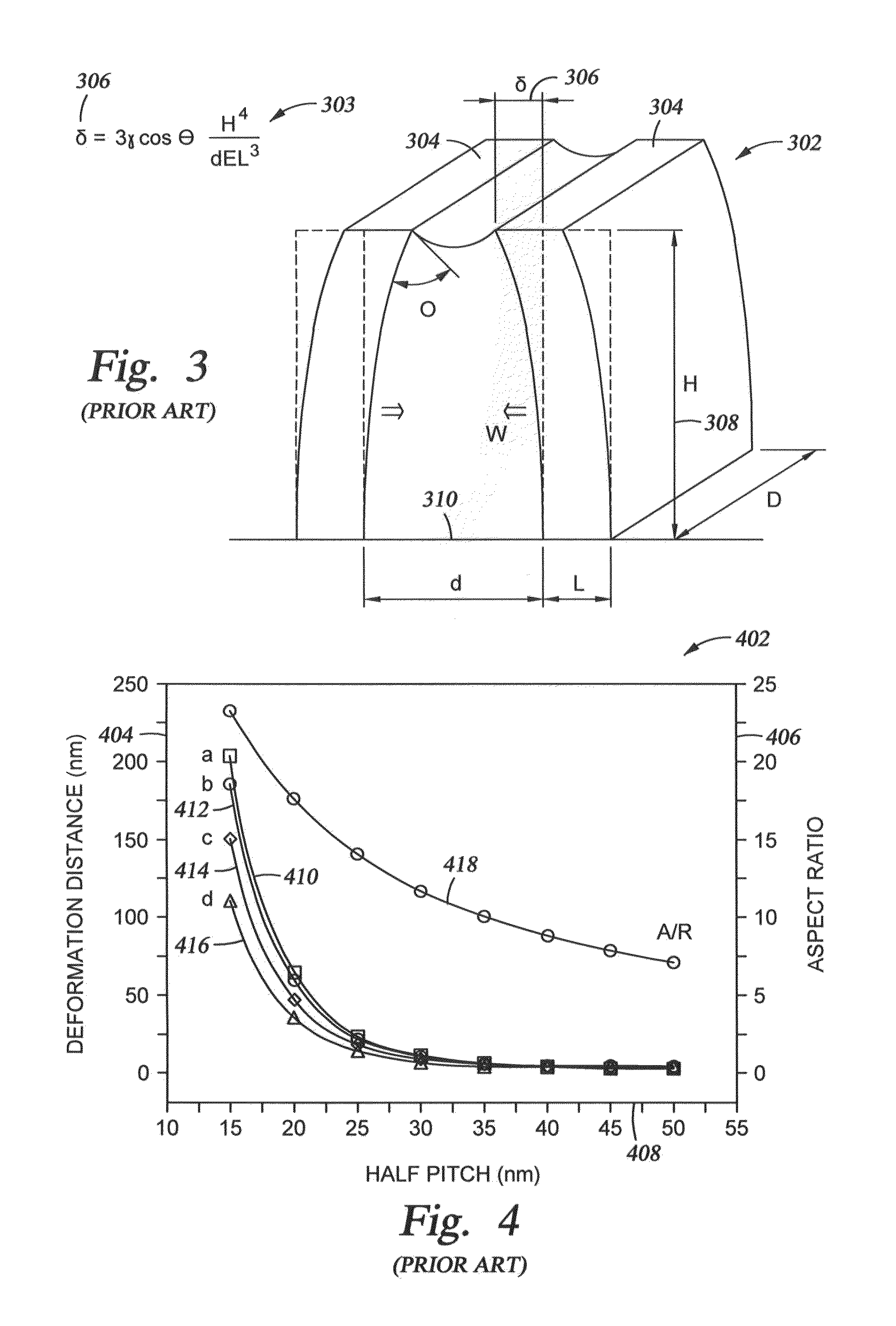

Stiction-free drying of high aspect ratio devices

InactiveUS20130081301A1Shorten the time periodNot to damageDrying solid materials with heatSolid-state devicesAspect ratioSurface tension

A method of removing a water-comprising rinse / cleaning material from the surface of a device which includes high aspect ratio features (an aspect ratio of 5 or greater) where sidewalls of the feature are separated by 50 nm or less without causing stiction between the feature sidewall surfaces. The method relies on the use of a low surface tension drying liquid which also exhibits a high evaporation rate. The method also relies on a technique by which the drying liquid is applied. Increasing the evaporation rate of the drying liquid and application of the drying liquid in the form of a vapor helps to eliminate stiction.

Owner:APPLIED MATERIALS INC

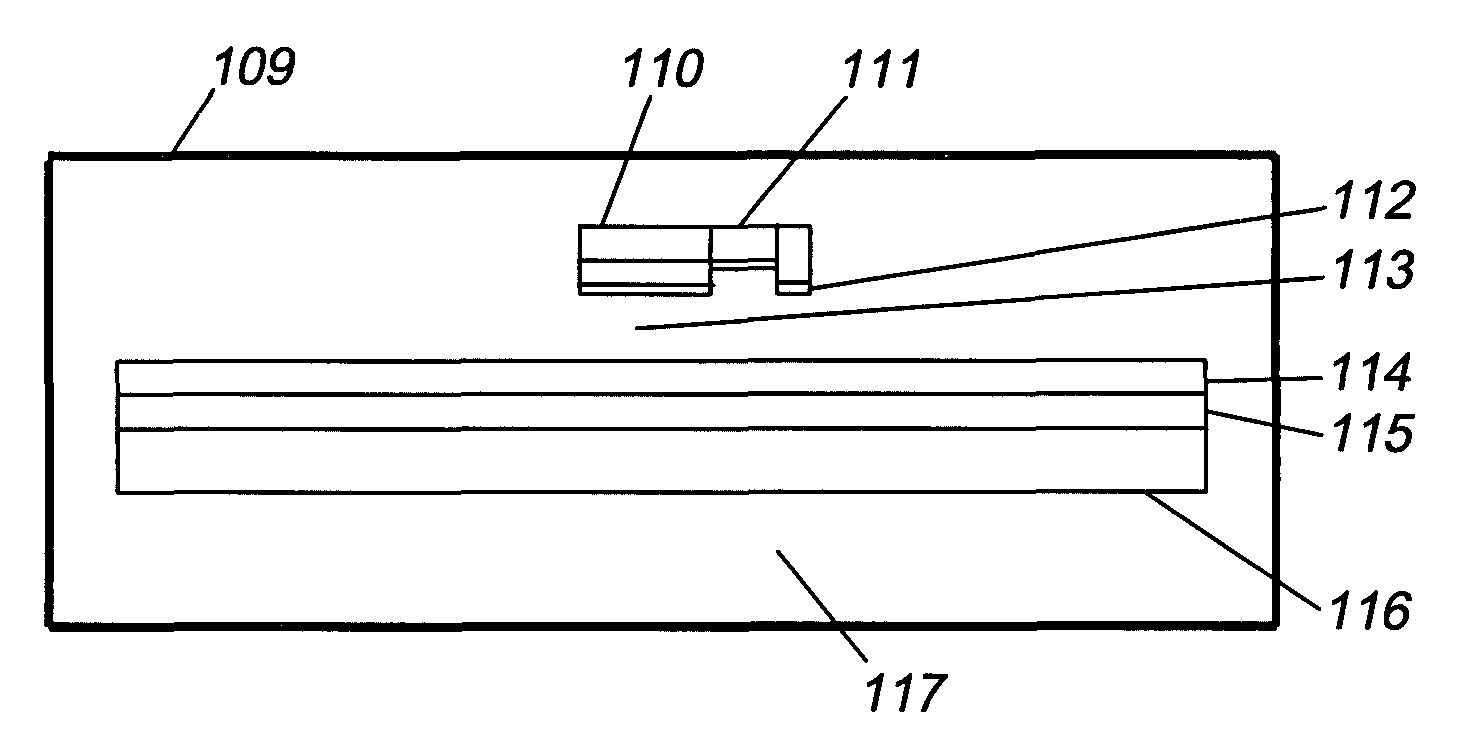

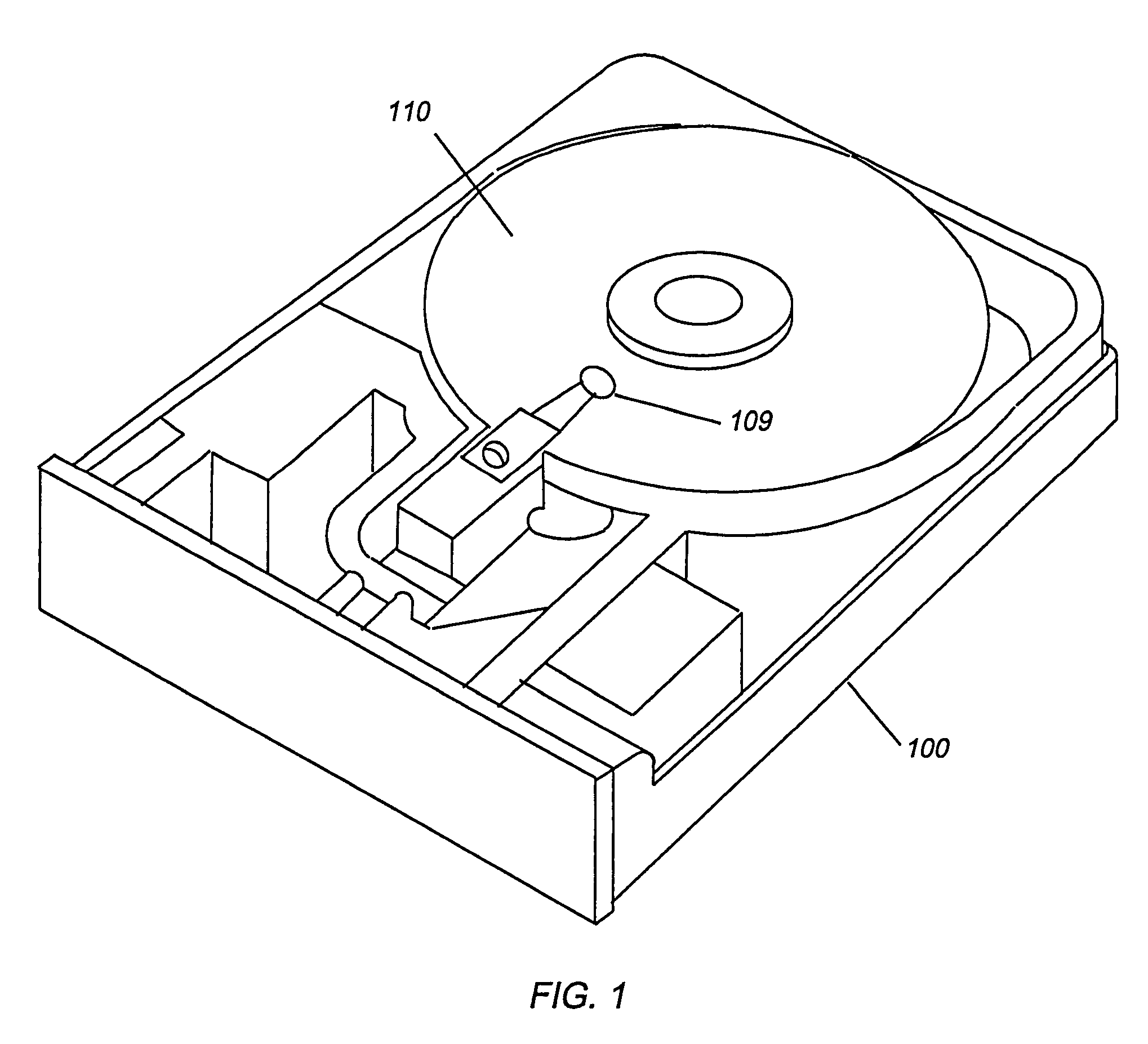

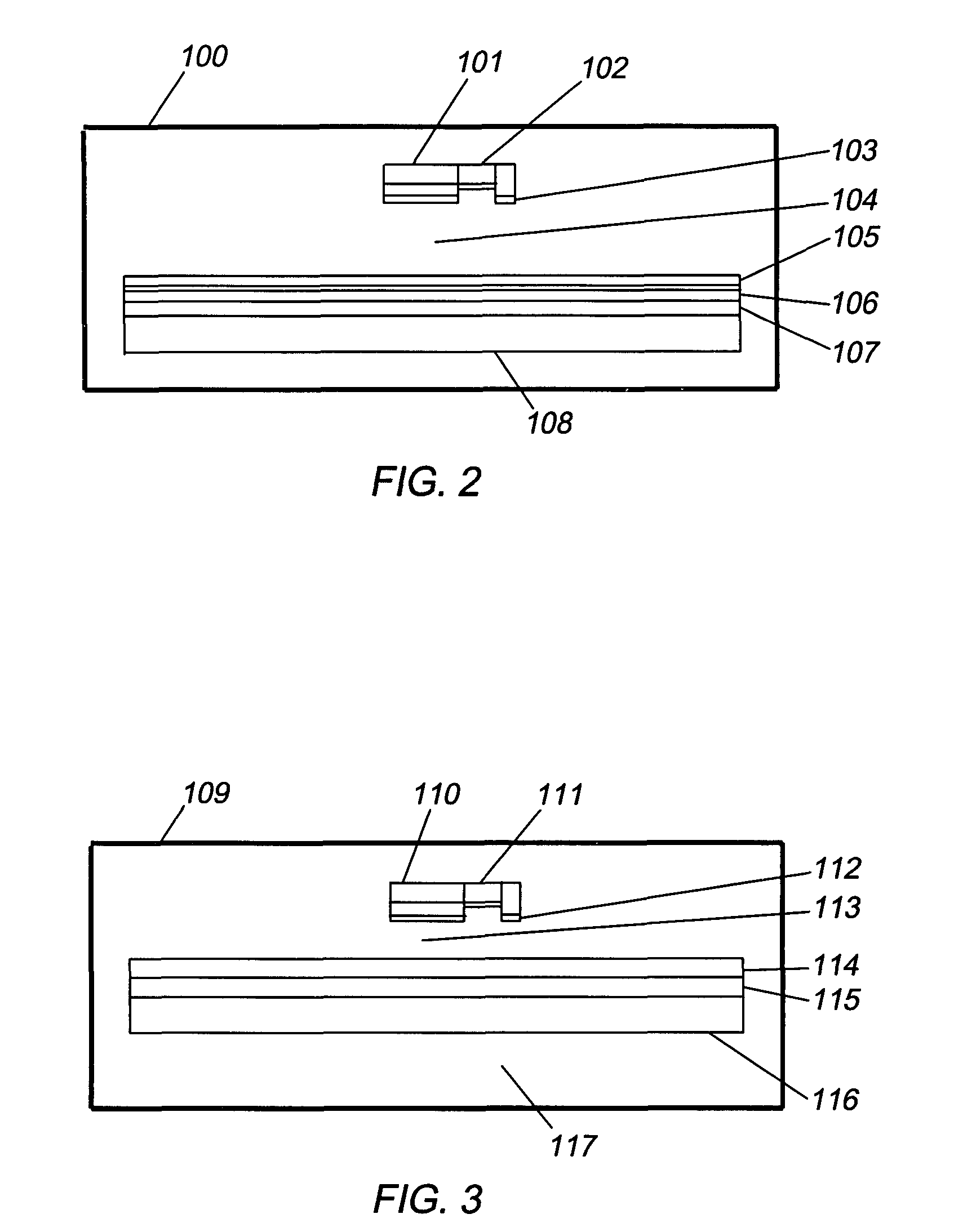

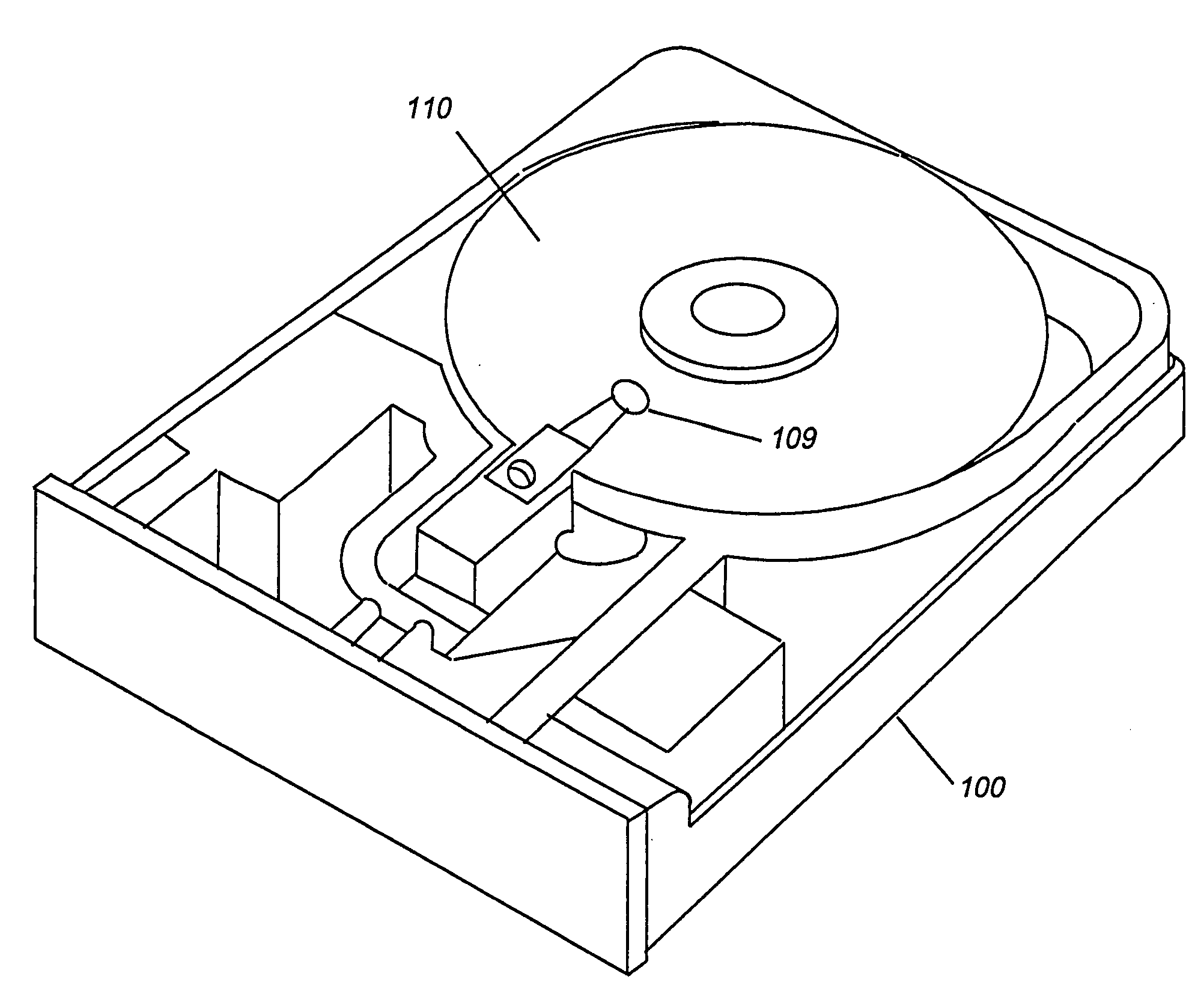

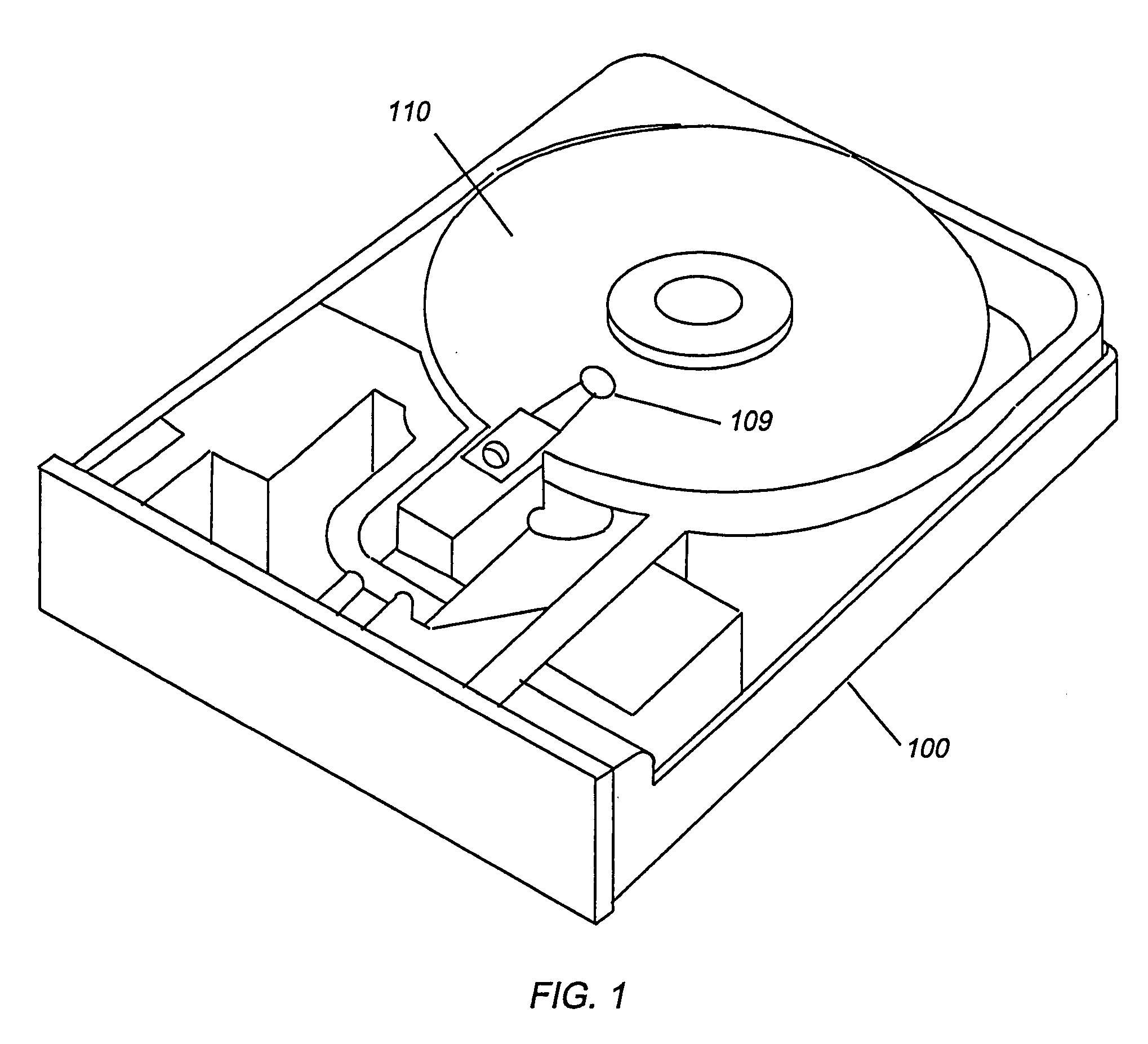

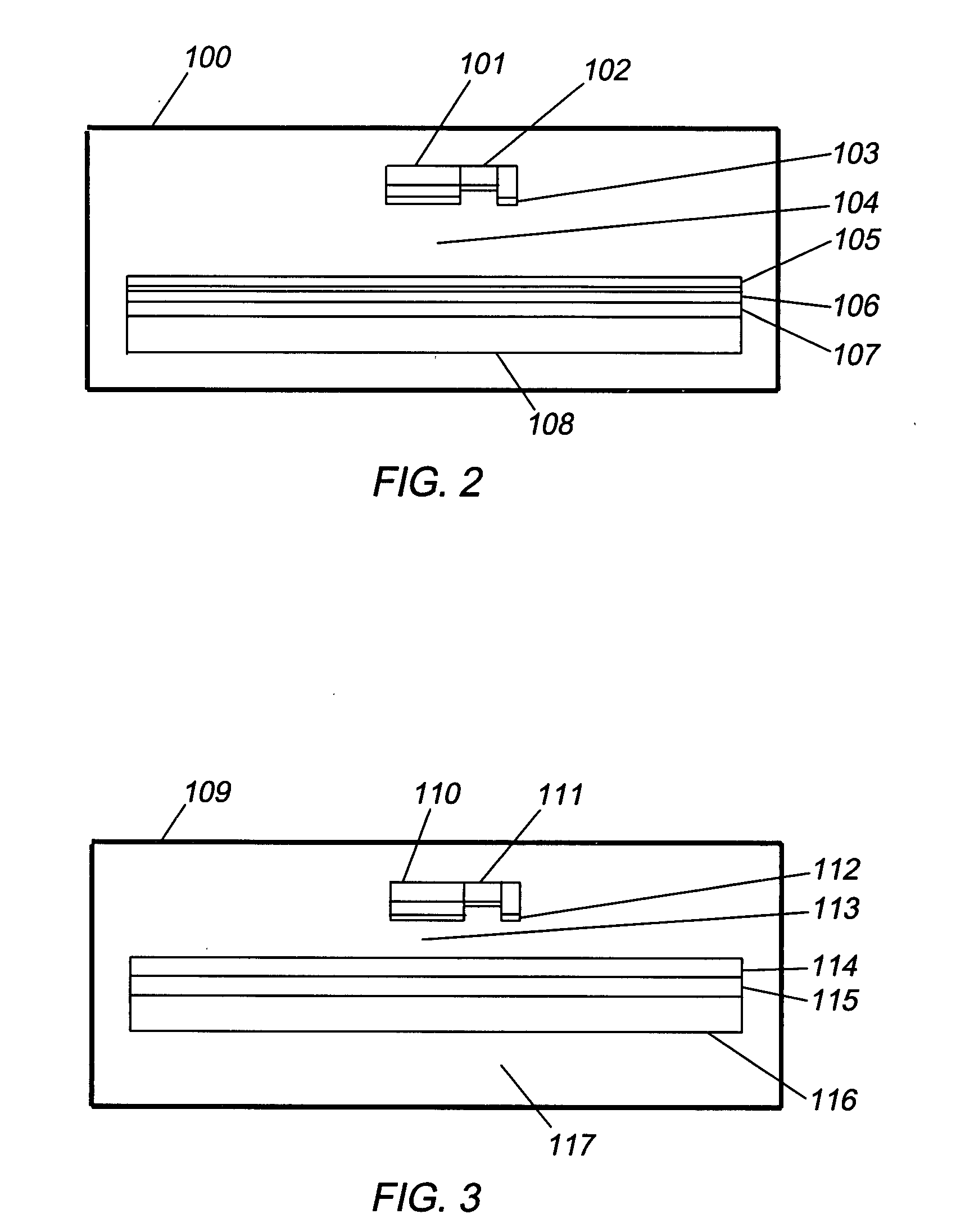

High performance computer hard disk drive with a carbon overcoat and method of improving hard disk performance

InactiveUS7961427B2Reduce seek timeIncrease areal densityManufacture head surfaceProtective coatings for layersHard disc driveHydrogen

Owner:GALLEON INT CORP +1

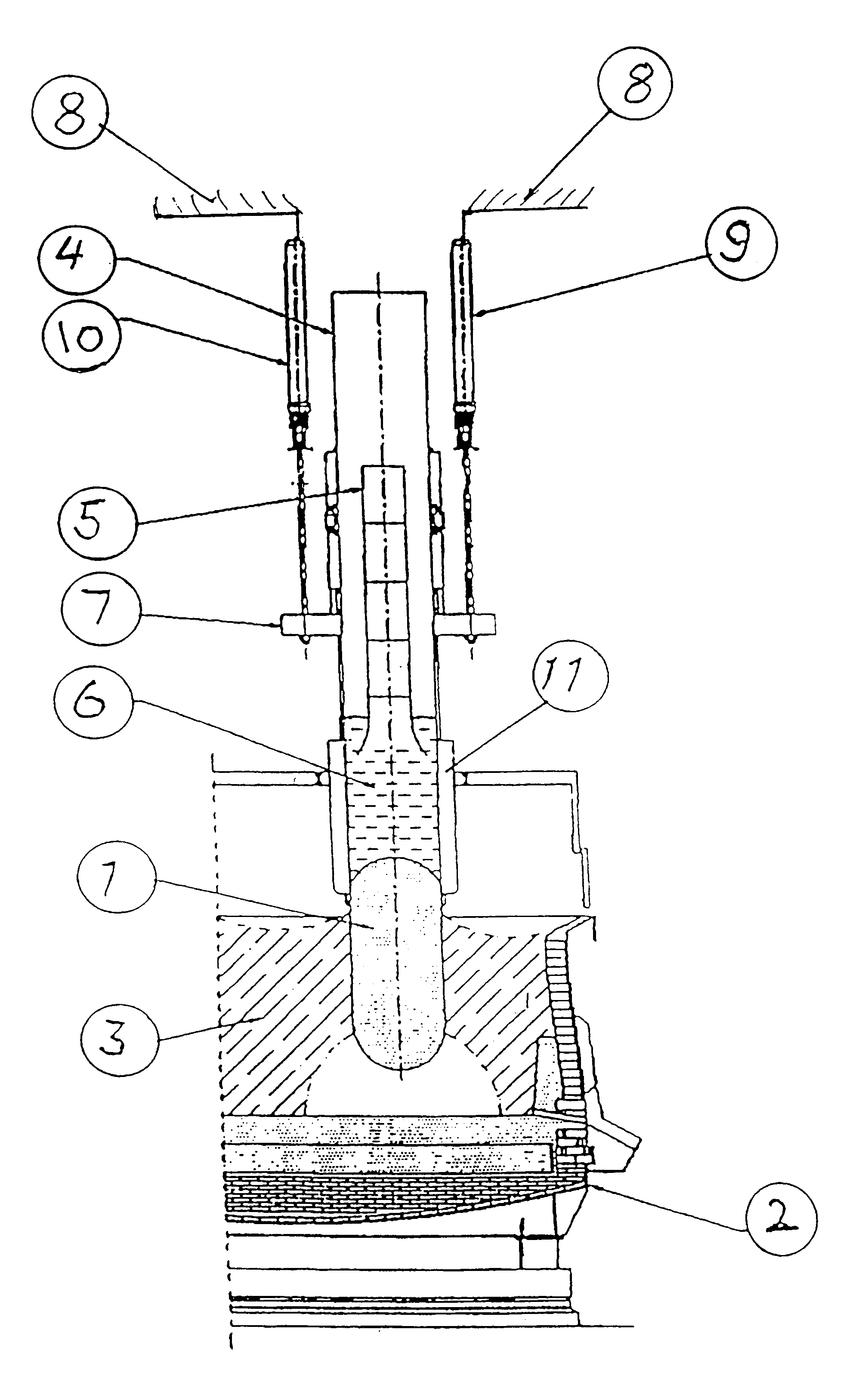

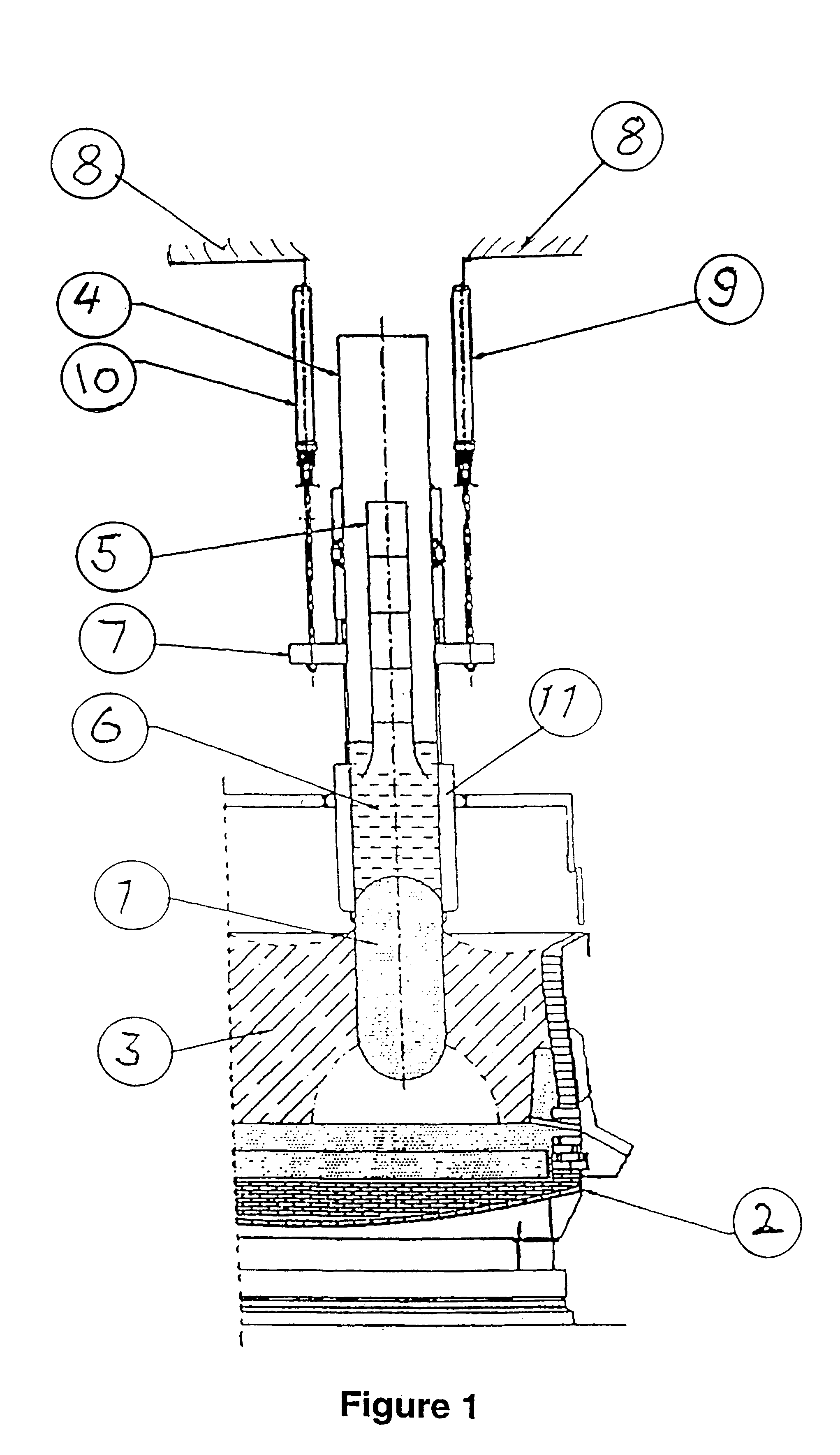

Method for weighing electrodes in electric smelting furnaces

InactiveUS6330270B1Eliminate frictionExclude influenceElectric discharge heatingSpecial purpose weighing apparatusOptoelectronicsElectrode

The present invention relates to a method for weighing an electrode submerged in the charge of an electric smelting furnace. The electrode is moved in vertical direction at least once, whereafter the electrode is lifted and the weight of the electrode is registered shortly after the electrode has been lifted.

Owner:ELKEM

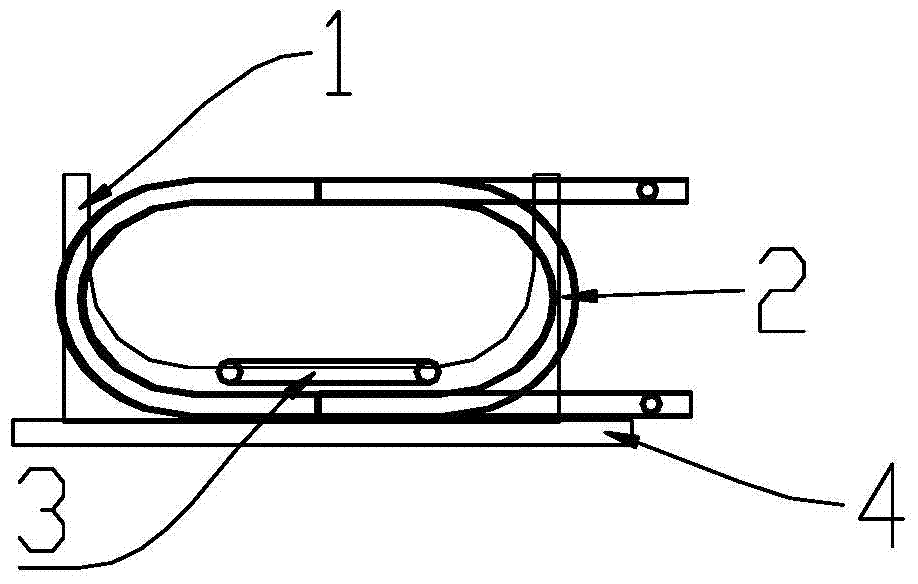

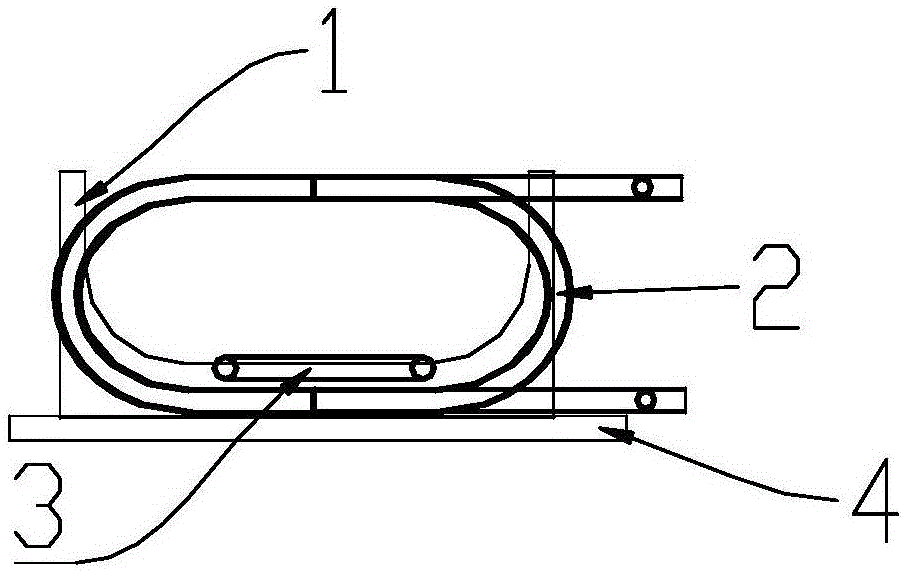

Device and a method for feeding packaging blanks

Owner:TETRA LAVAL HLDG & FINANCE SA

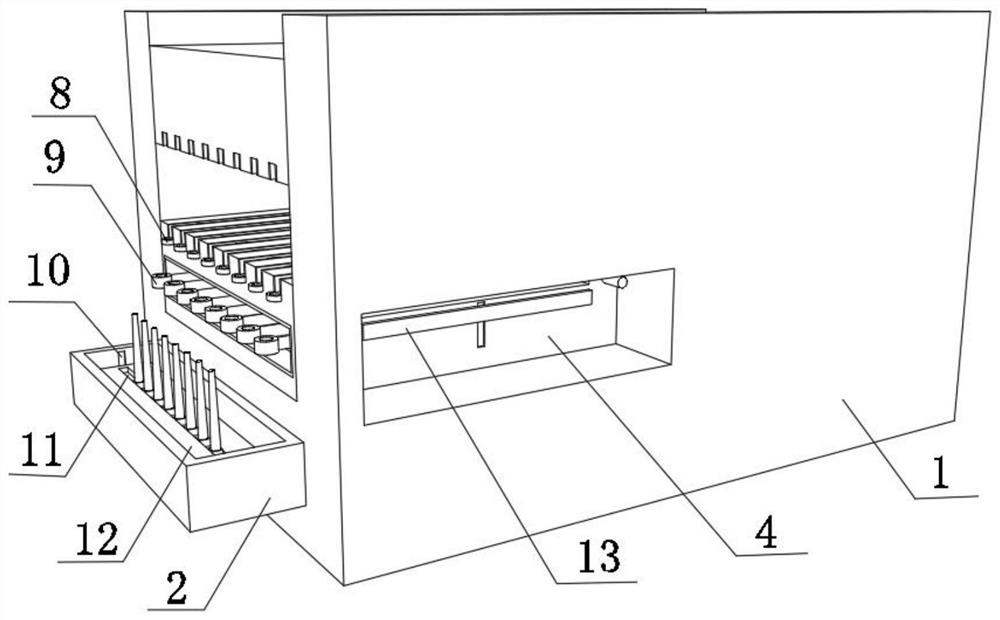

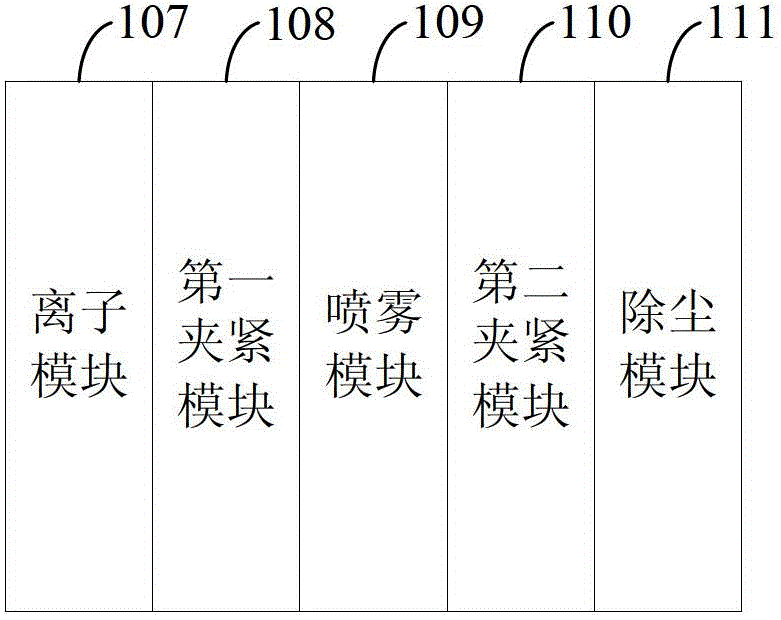

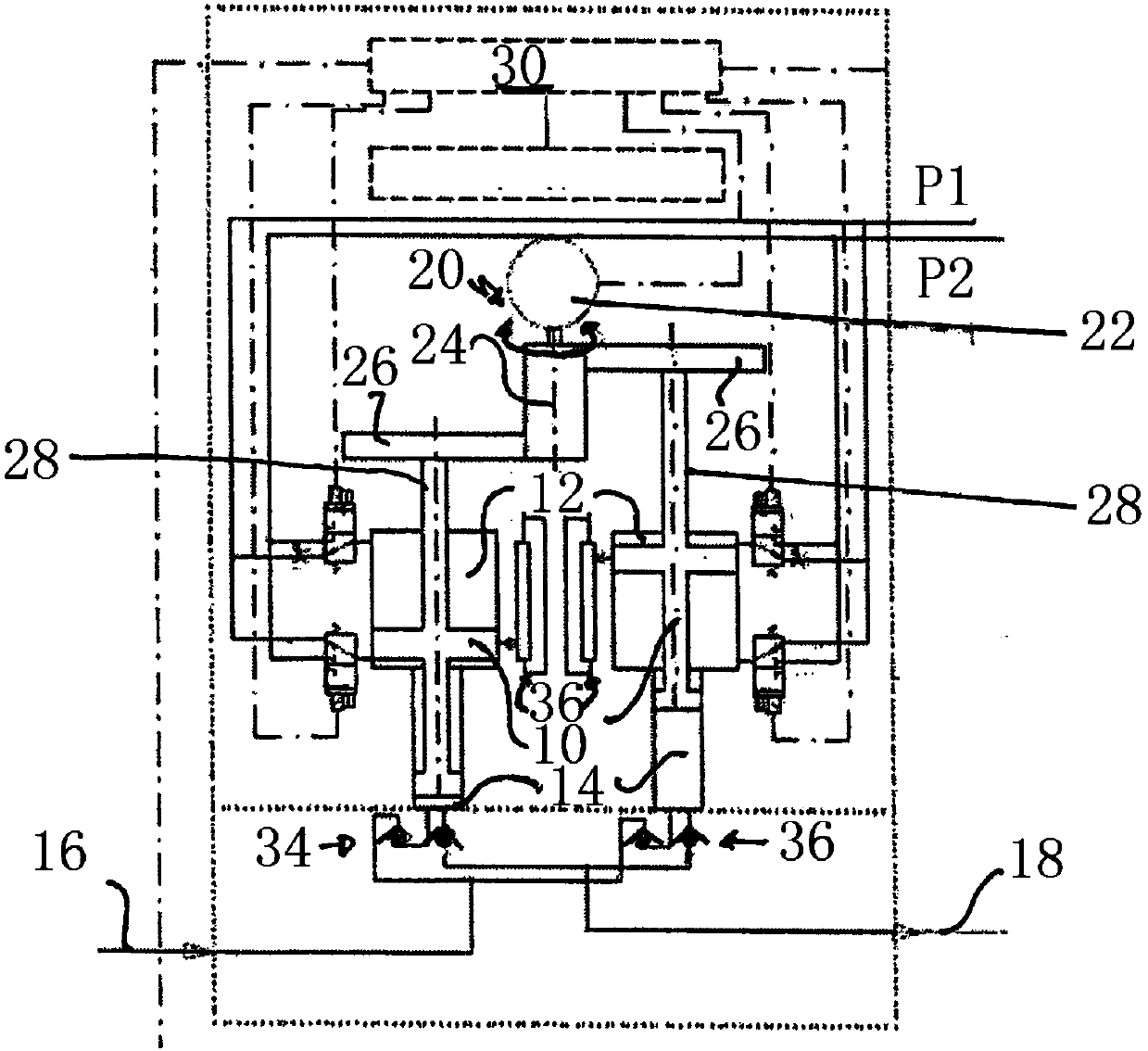

Component, system and method for cleaning lens

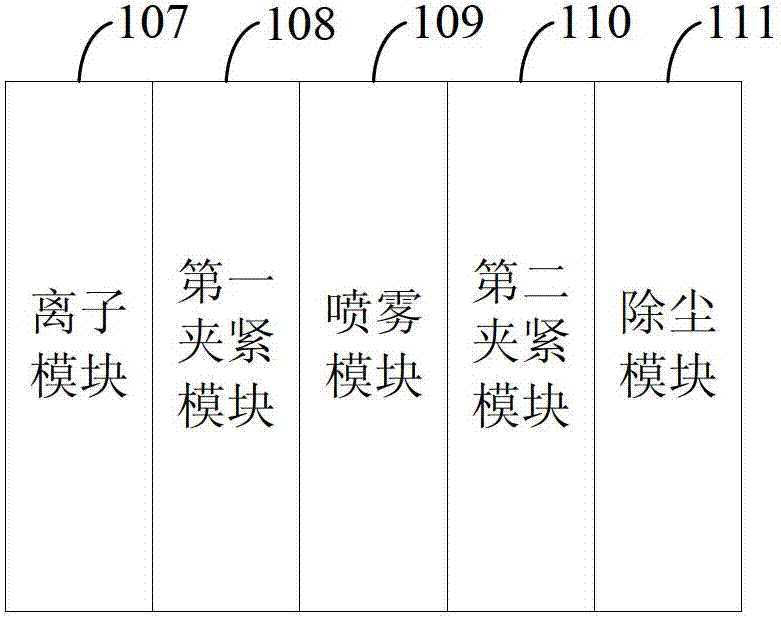

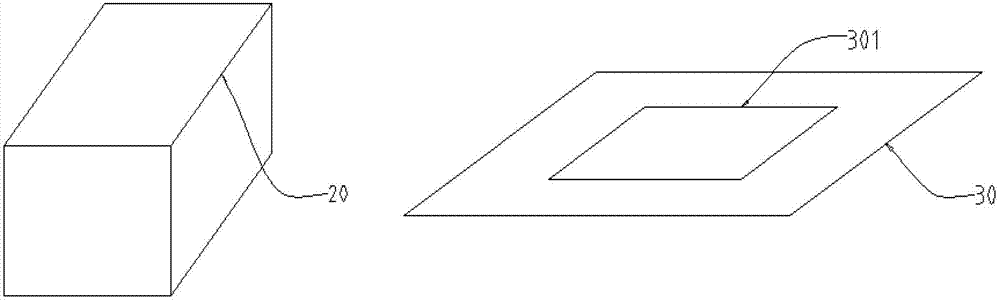

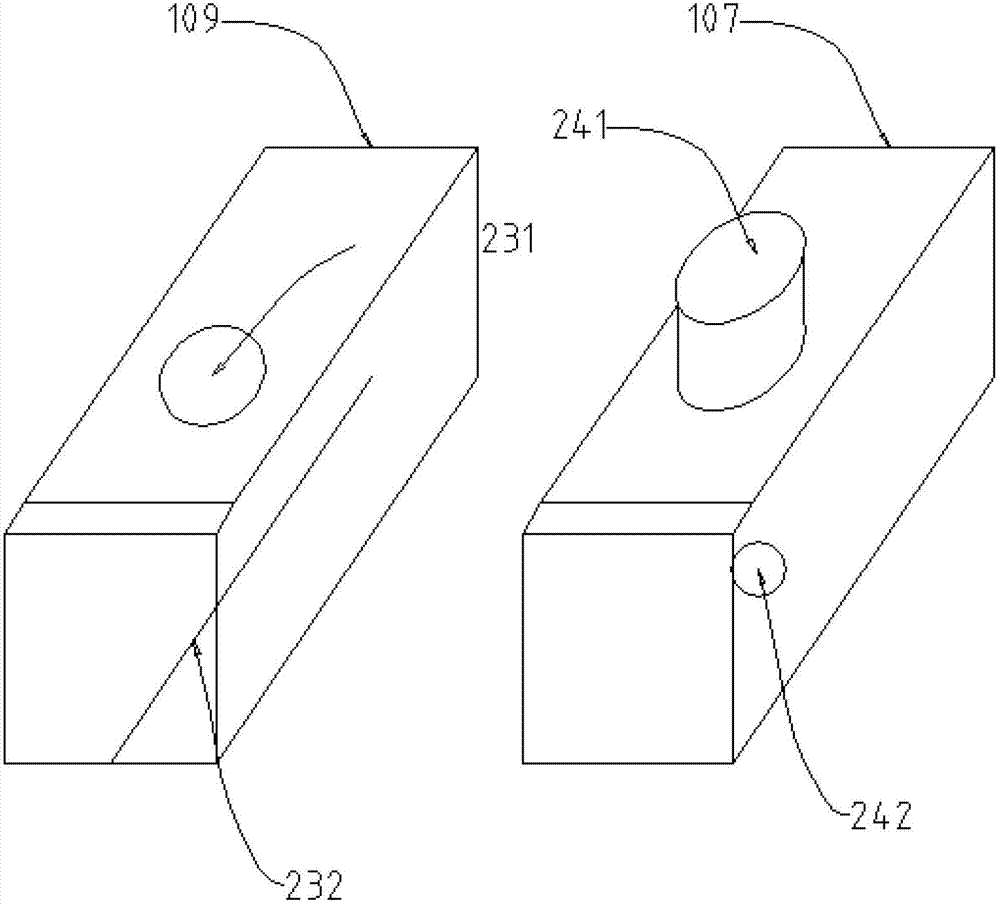

InactiveCN102728586AEliminate static frictionWon't stayFlexible article cleaningEngineeringLens plate

The invention belongs to the field of lens cleaning and discloses a component, a system and a method for cleaning lens. The component for cleaning lens provided by the invention comprises an ion module, a first clamping module, a spraying module and a second clamping module. The spraying module performs spray wash on the surface of the lens by atomized alcohol, and a cleaning material is clamped by the first clamping module and the second clamping module to remove the impurity on the surface of the lens after spray wash. The surface of the lens is dried by the ion module and the frictional static on the surface of the lens is eliminated. The cleaning efficiency is high and the lens can be cleaned more cleanly without scratch on the surface of the lens. In addition, the cleaning method is simple and the operation is easy.

Owner:HUAZHONG UNIV OF SCI & TECH

High performance computer hard disk drive and method

InactiveUS20080291570A1Low costReduce storageManufacture head surfaceProtective coatings for layersHard disc driveHydrogen

A high performance hard disk drive is disclosed in which a flying read / write head runs in contact or in near contact with a rotating platter. In this design there is no wear of the hard disk platter or flying head due to both head and platter being coated with an amorphous carbon that has an exceptionally low coefficient of friction in a sealed, inert gas environment. The overcoat contains carbon in the range between about 52 and 80 atomic percent and hydrogen in the range between about 20 to 48 atomic percent. There is no lubricant required in this design, which eliminates a significant cause of hard drive failure from oxidation of the lubricant, stiction and rippling of the lubricant. This contact method achieves a high areal density with no wear, within a robust, hermetically sealed environment.

Owner:GALLEON INT CORP +1

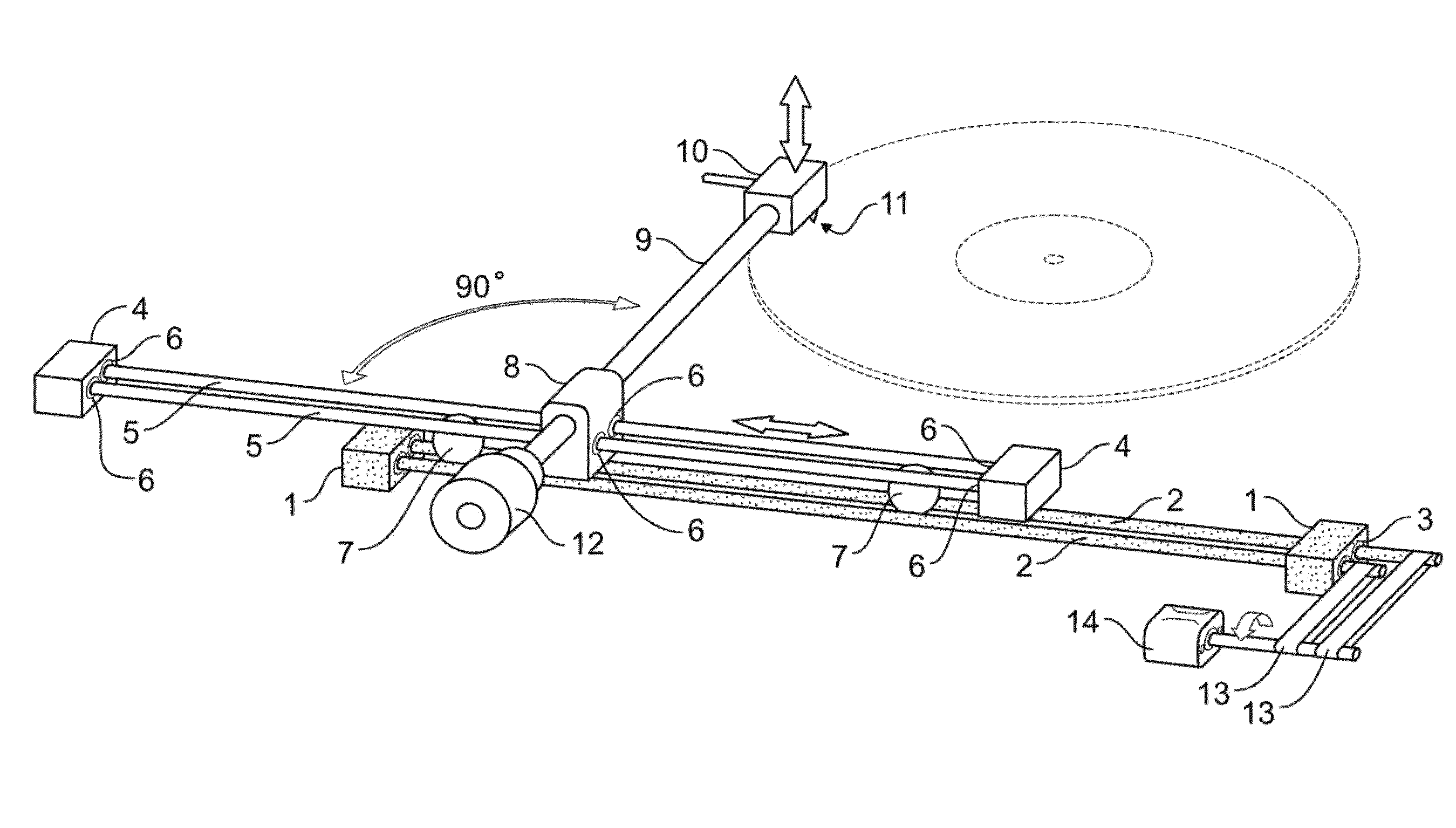

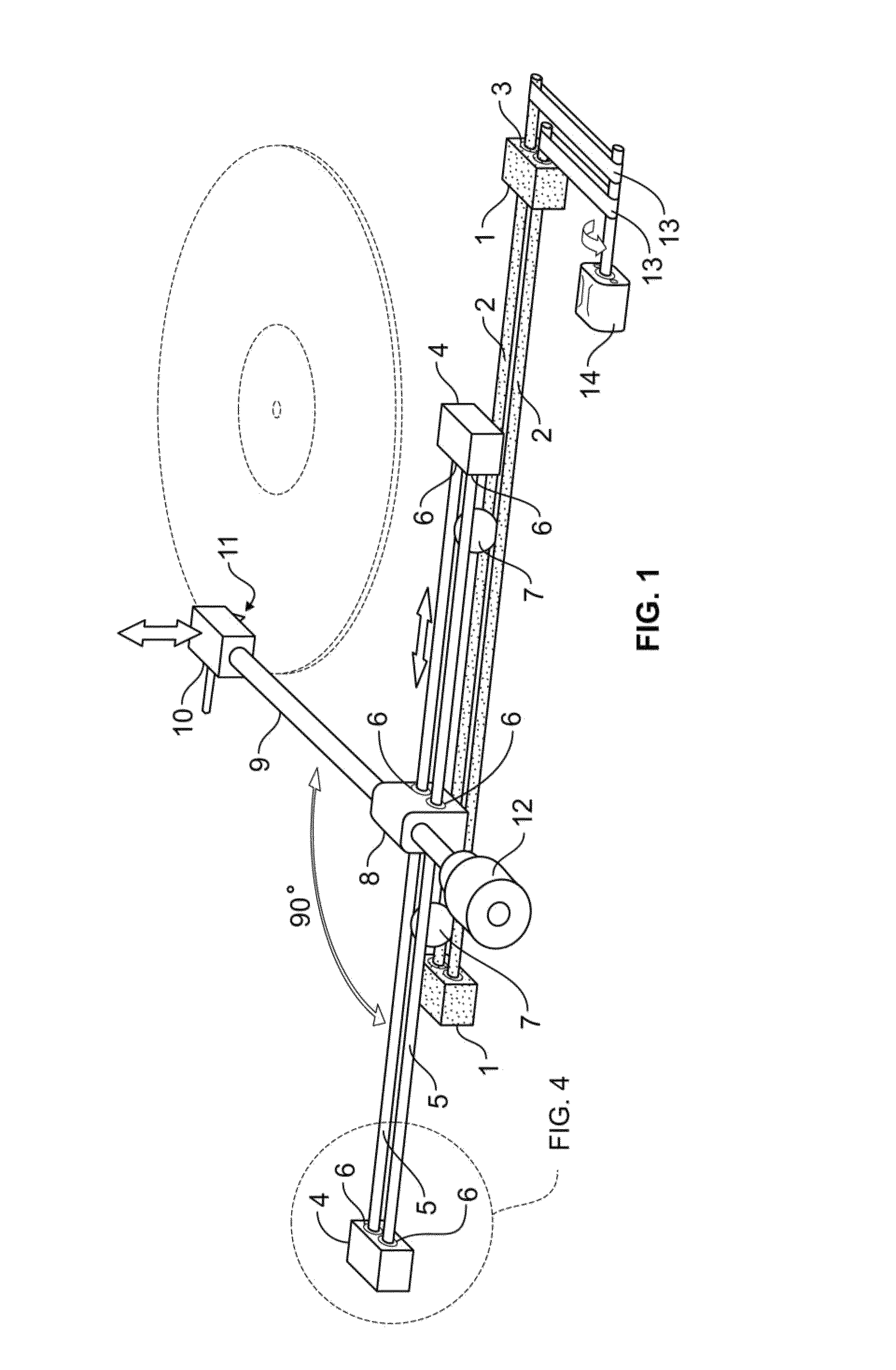

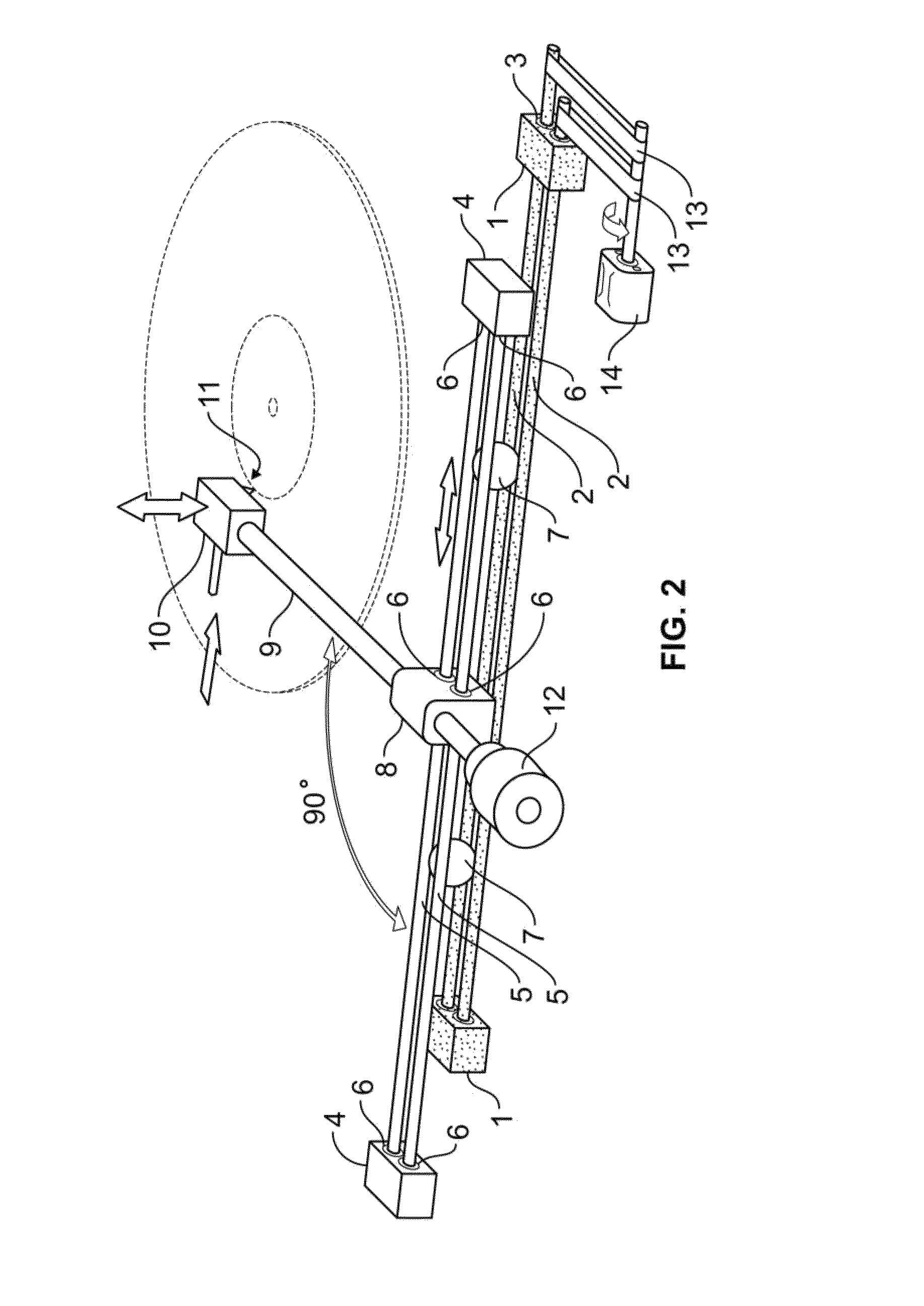

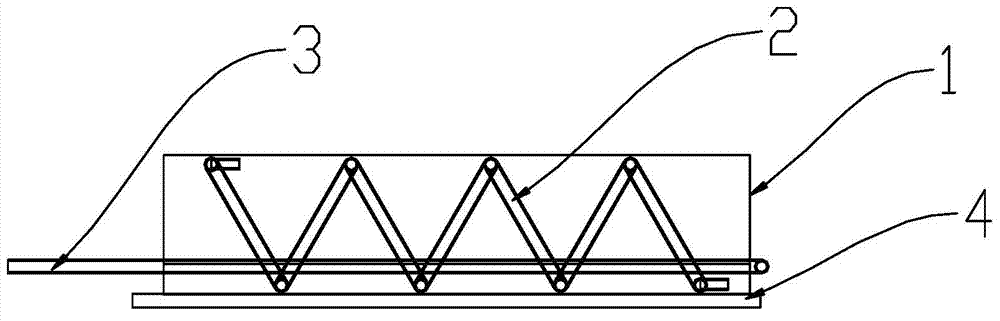

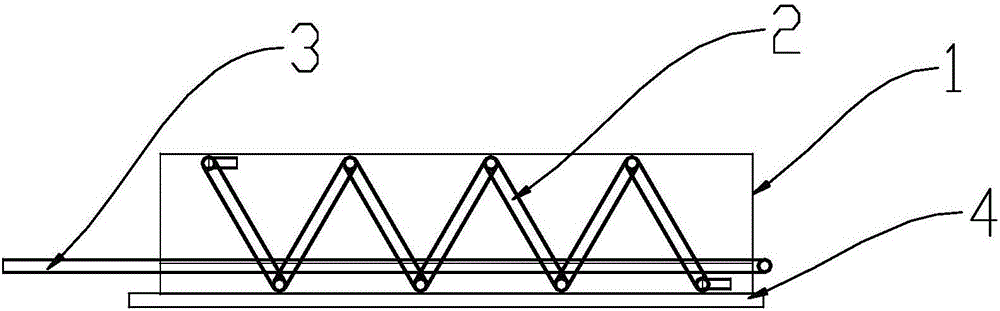

Low friction linear tracking tone arm

InactiveUS9019806B1Reduce weightReduce lateral frictionTrack finding/aligningRecord information storageRolling resistanceLow distortion

This invention is provides a means of playing LP records with minimal distortion. Low distortion is achieved by eliminating tracking error normally associated with pickup cartridges mounted to pivoting tone arms. This invention discloses a tone arm that constrains the motion of the stylus to straight radial path, mimicking the cutting path of the record lathe, supported on parallel rails by free rolling spherical bearings. Unlike many previous linear tracking tone arms, this invention does not rely on air pressure or servo motor mechanisms. The use of free rolling bearings or axles between parallel tracks fashioned from rails, rods or tubes, eliminates all sources of lateral friction other than pure static and rolling friction of the balls on the rails, rods or tubes. In the preferred embodiment, the fixed rods or tubes are driven synchronously, thereby eliminating static friction of the supporting rolling balls. Friction is further reduced using magnetic or buoyant support of the tone arm to reduce bearing load to that amount minimally sufficient to maintain full contact between the rolling balls and the upper and lower rods.

Owner:BOWDEN SR THOMAS LLOYD

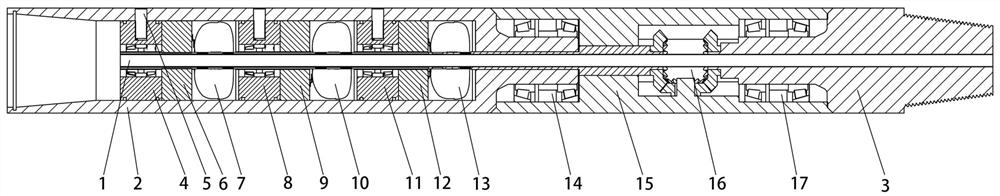

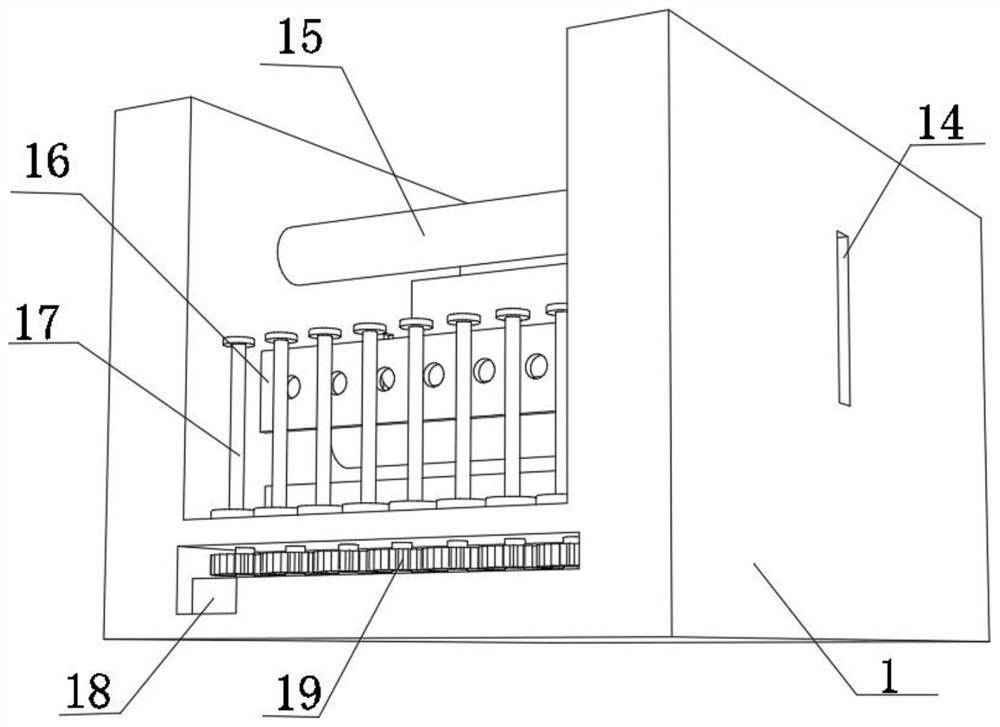

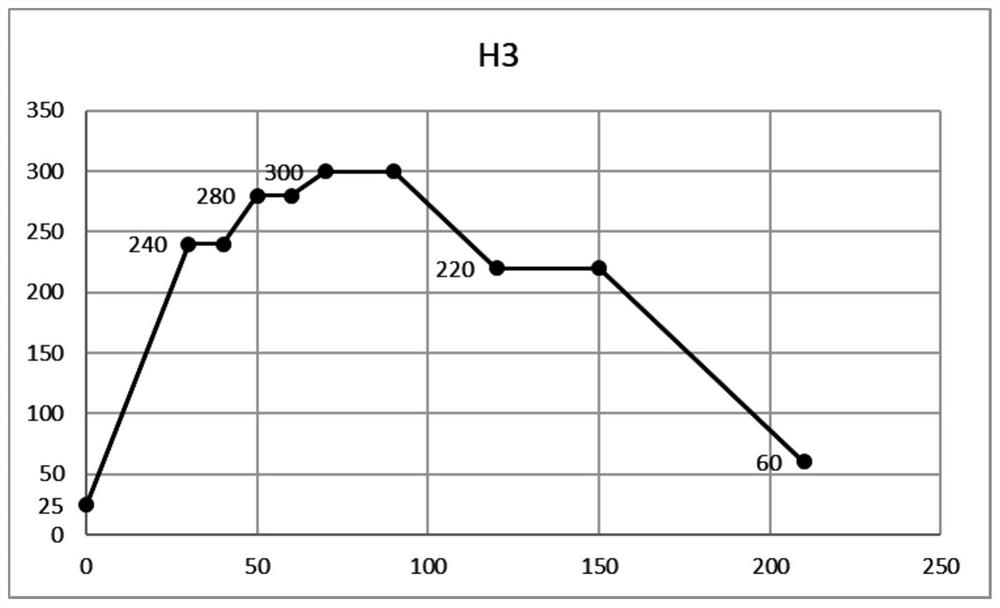

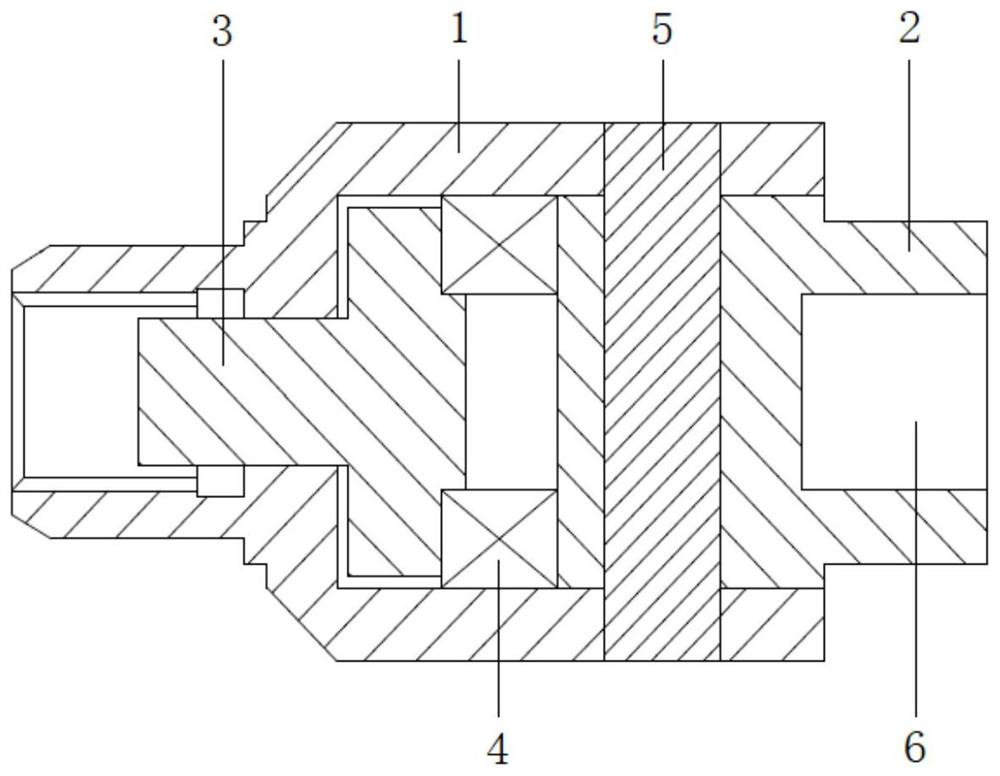

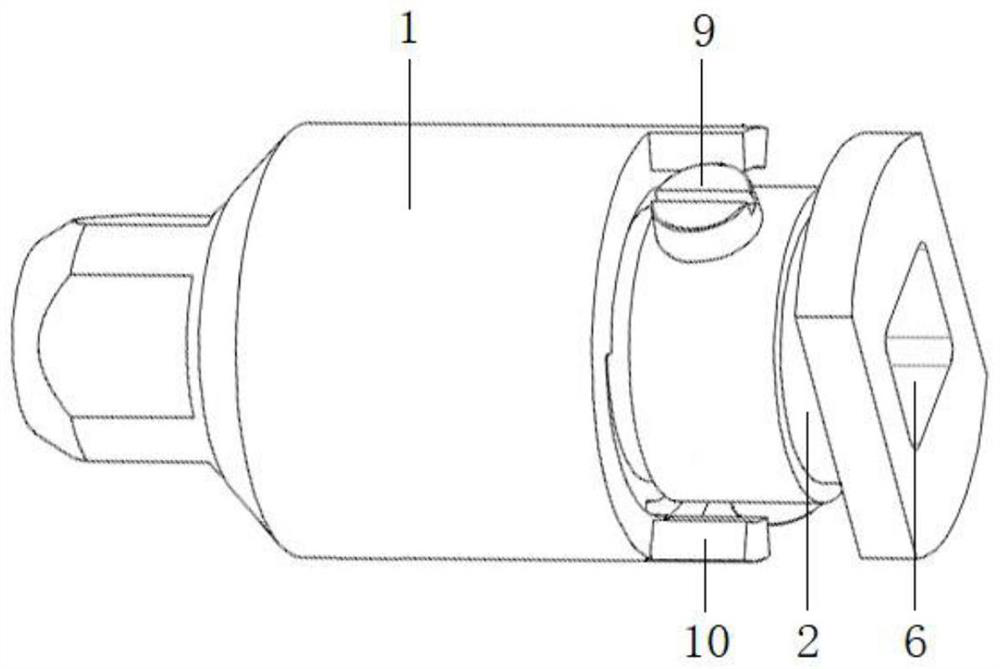

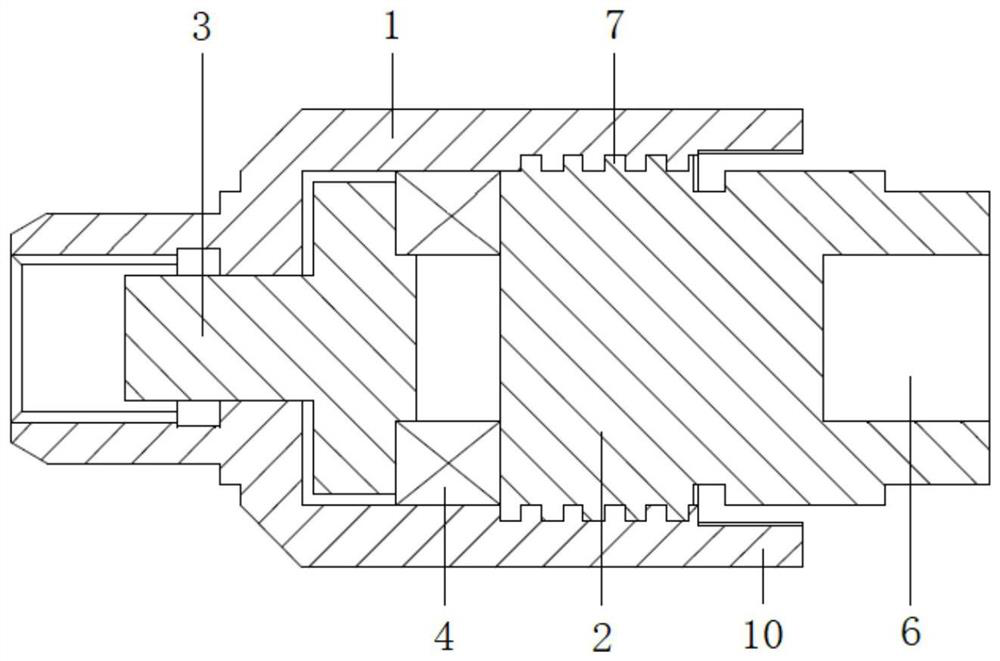

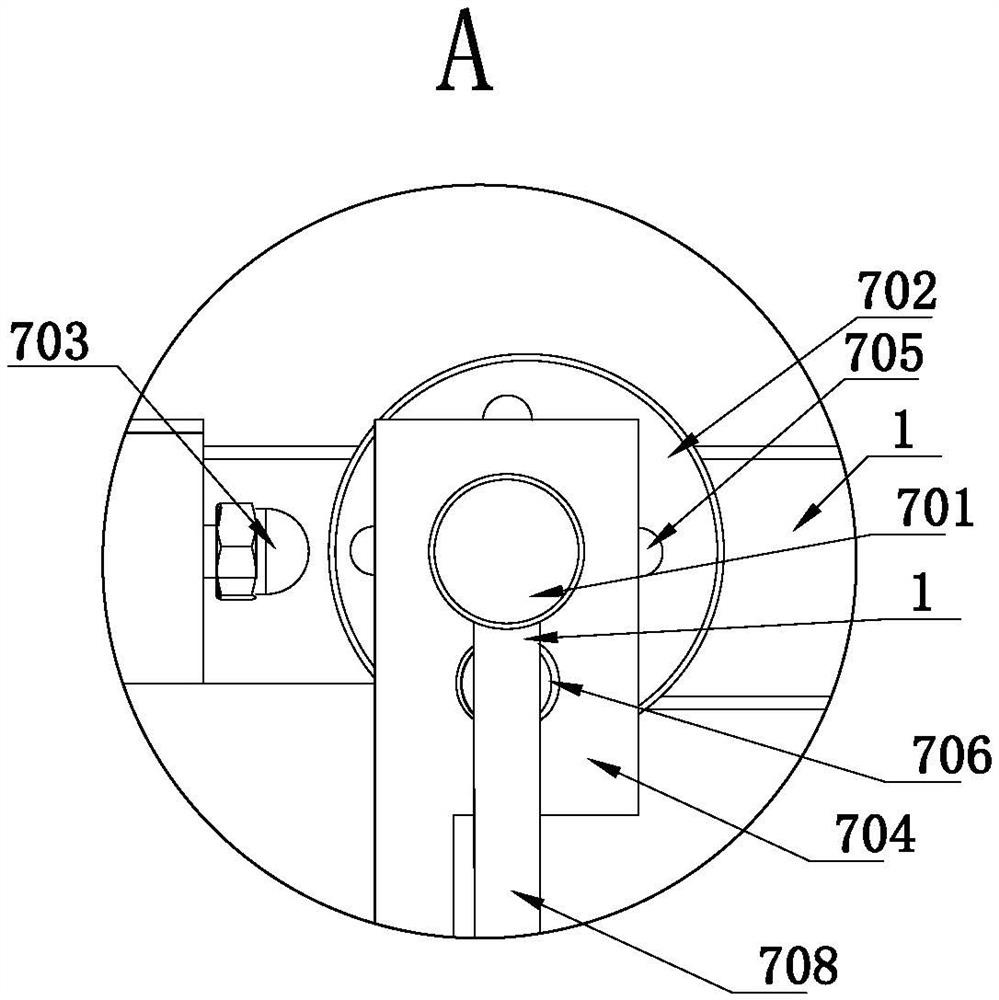

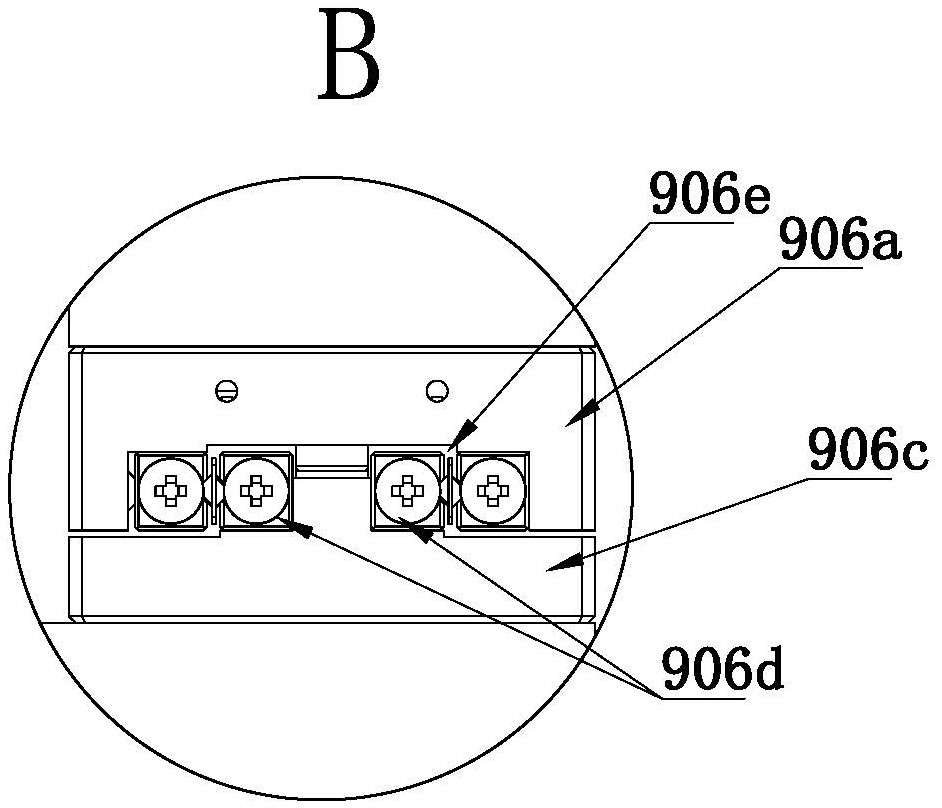

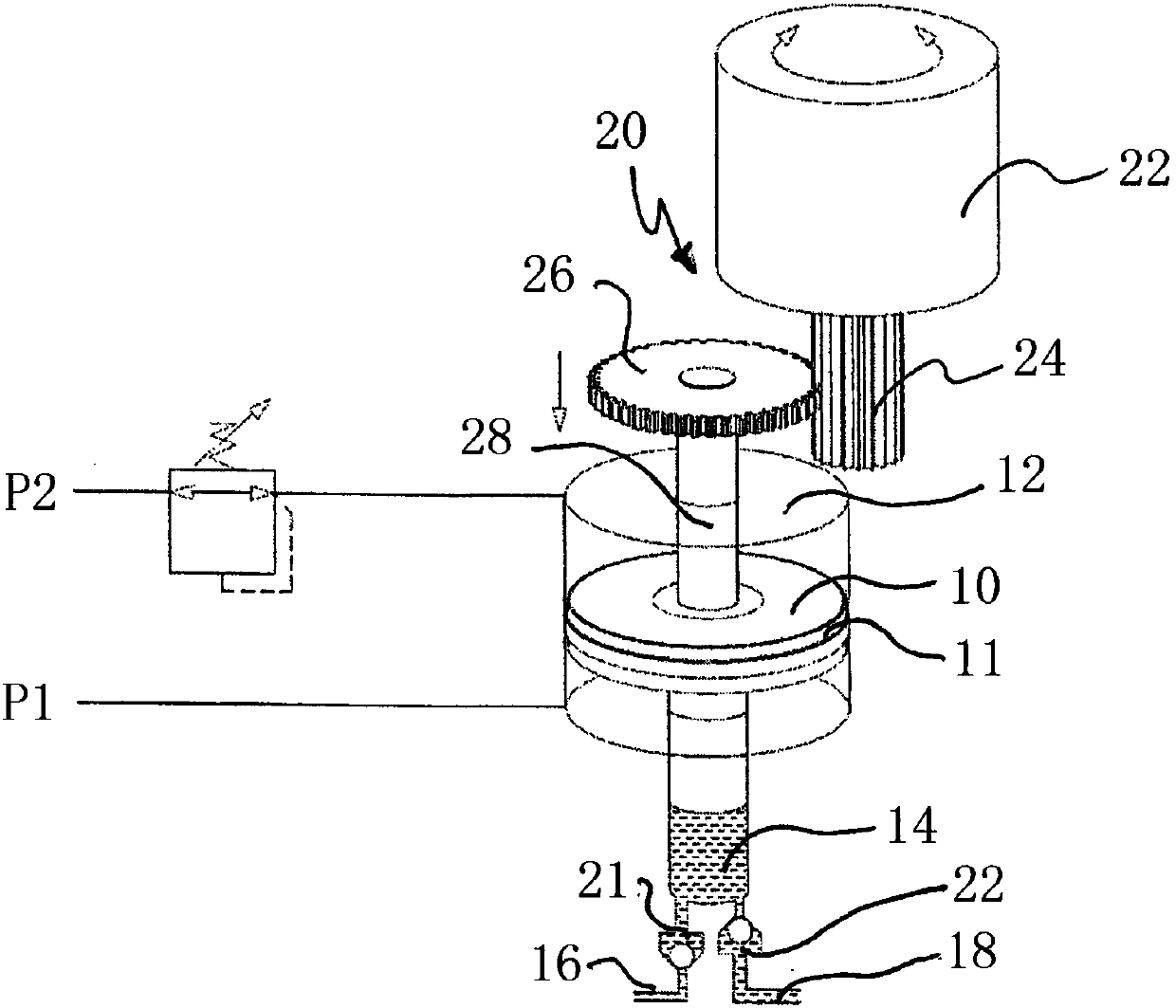

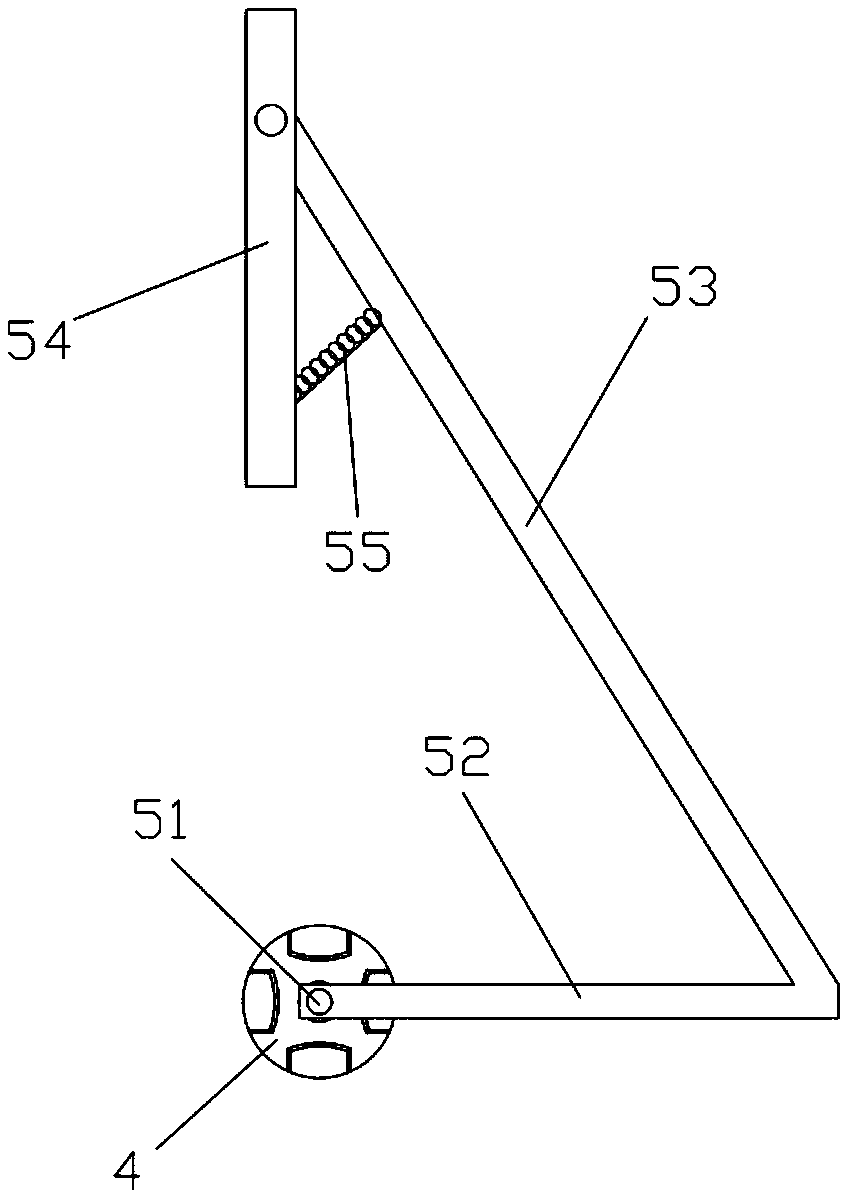

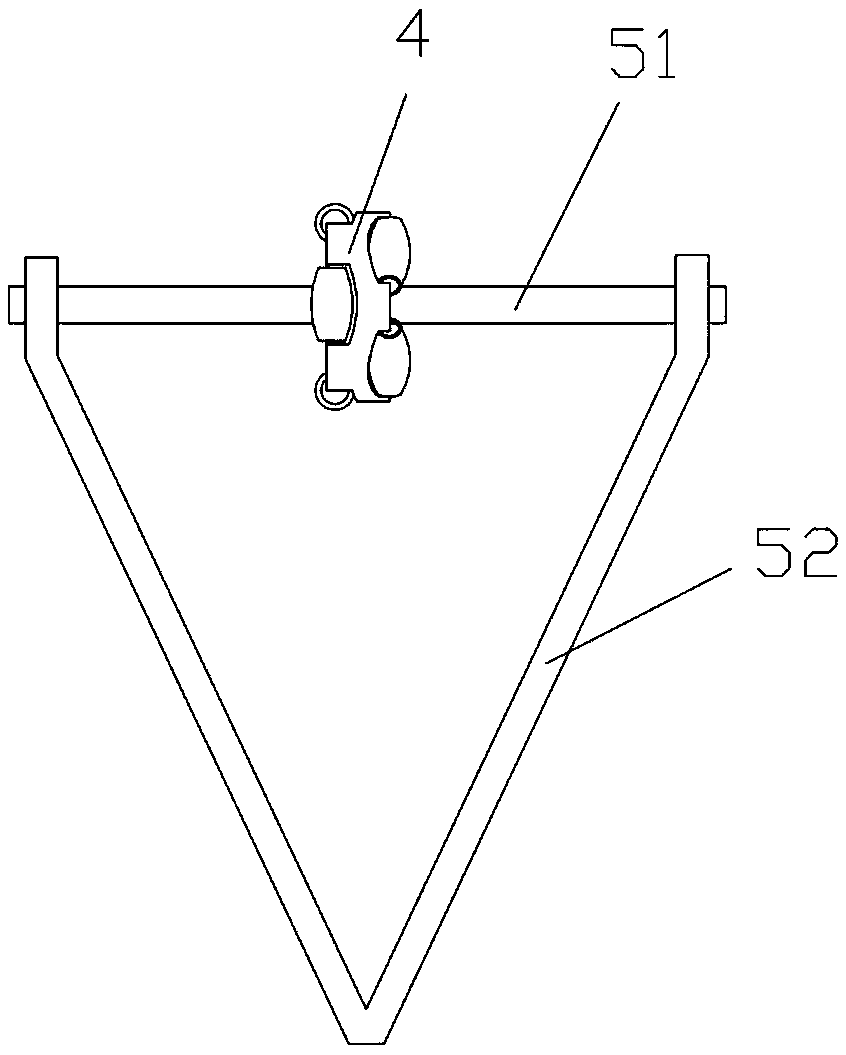

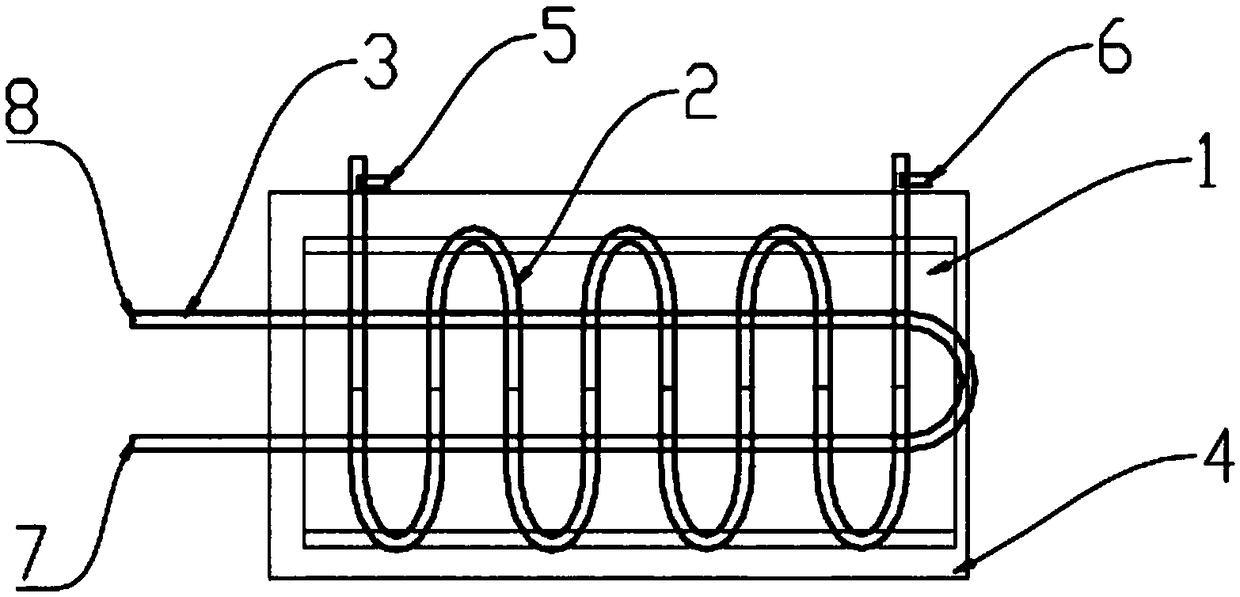

Downhole friction reduction and resistance reduction tool and method based on mechanical decoupling

ActiveCN114293913ALow costEliminate static frictionSurveyDrilling rodsFriction reductionThermodynamics

The invention relates to an underground friction and resistance reducing tool and method based on mechanical decoupling, and belongs to the technical field of oil and gas resource drilling tools. The invention discloses an underground friction reduction and resistance reduction tool and method based on mechanical decoupling. The underground friction reduction and resistance reduction tool comprises an upper shell, a lower shell, a lower connector and a drilling fluid return pipe. An unloading connecting assembly I, a torque axial reversing assembly and an unloading connecting assembly II are sequentially arranged in the lower shell. A transfer positioning device I, a power input device, a torque increasing device I, a transfer positioning device II, a power separation device I, a torque increasing device II, a transfer positioning device III, a power separation device II, a torque increasing device III, a transmission shaft I and a transmission shaft II are sequentially arranged in the upper shell. The working torque of the downhole friction and resistance reducing tool is controlled by directly adjusting the drilling speed of a drill column through ground operators, so that sliding guide drilling under the condition that the drill column rotates is achieved, and the technical problems that the friction resistance of the drill column is high, backing pressure is serious, the mechanical drilling speed is low, and a horizontal section is difficult to extend are solved.

Owner:SOUTHWEST PETROLEUM UNIV

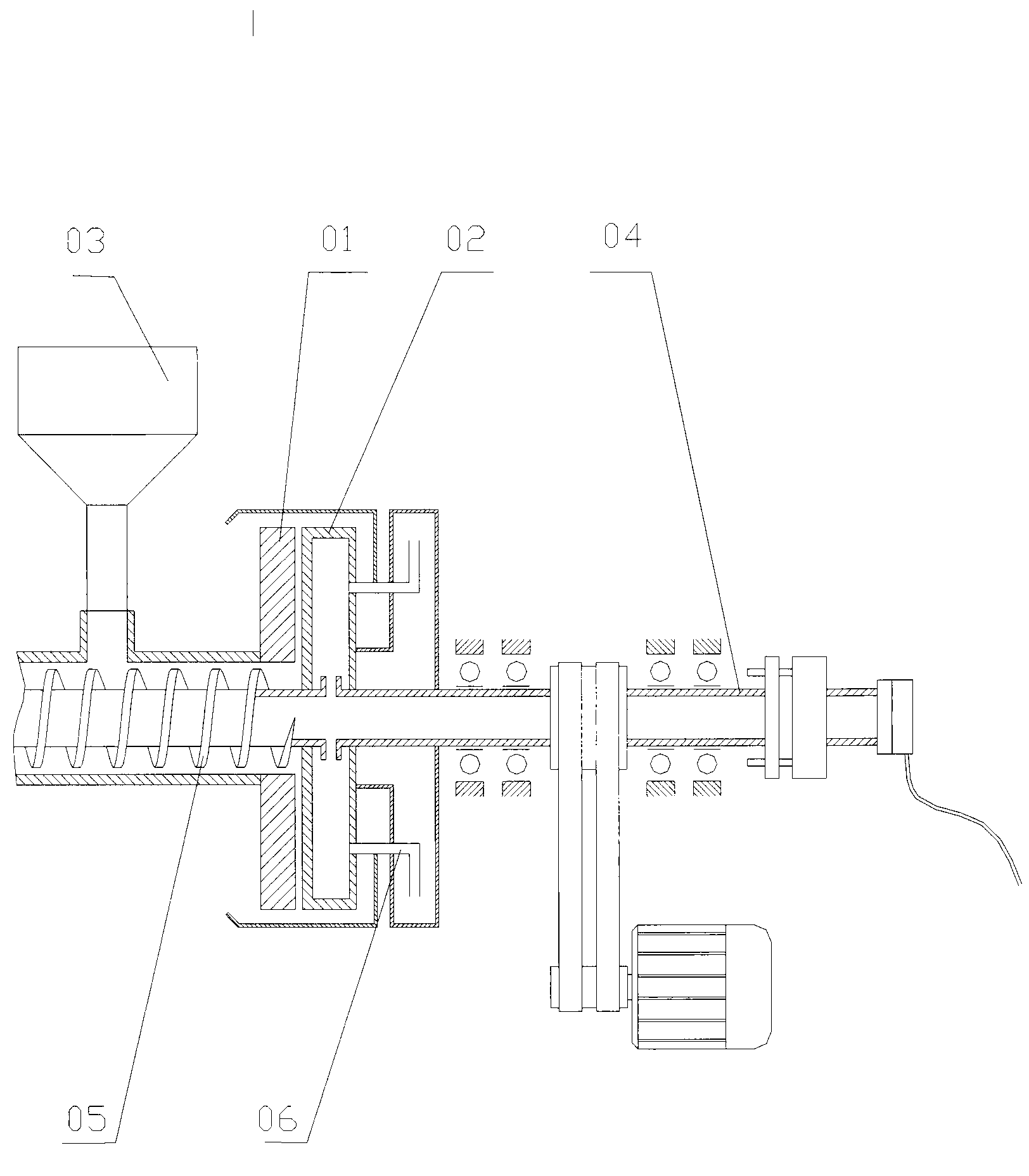

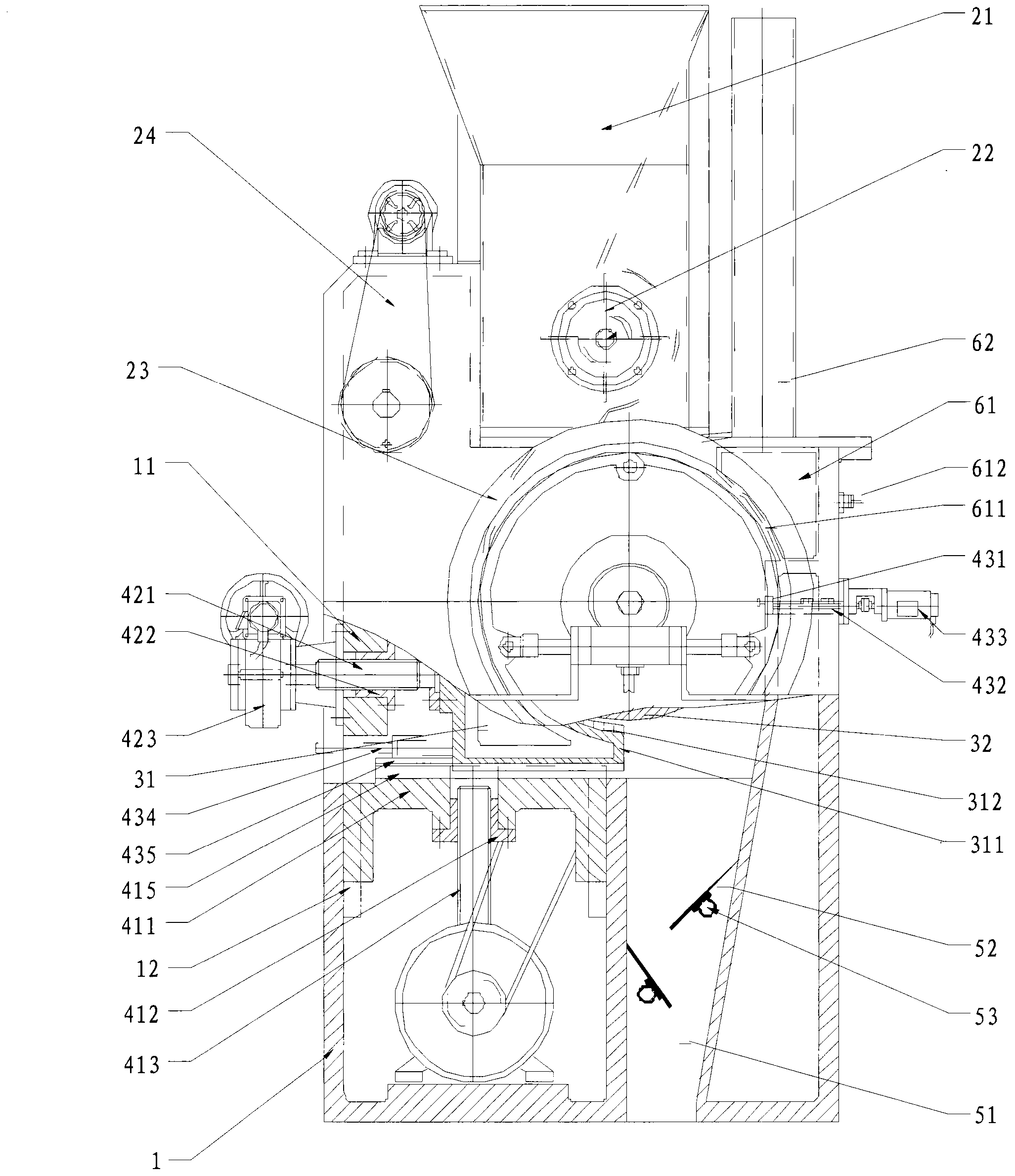

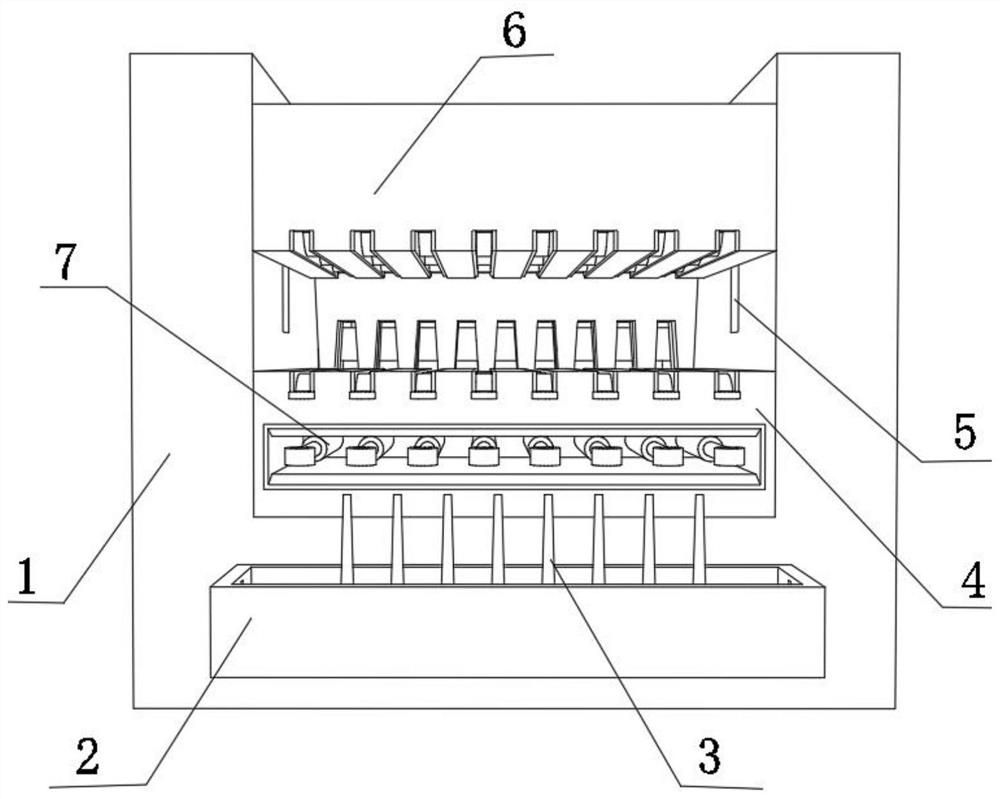

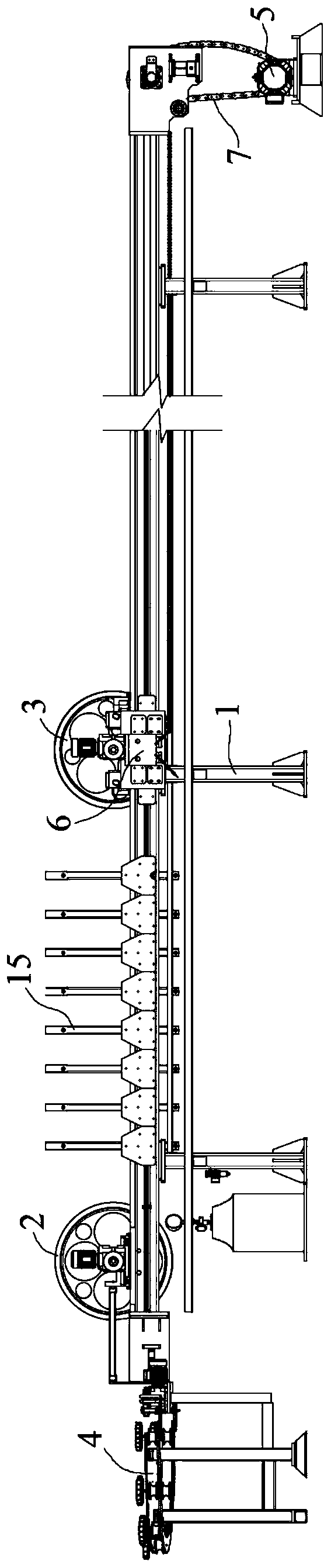

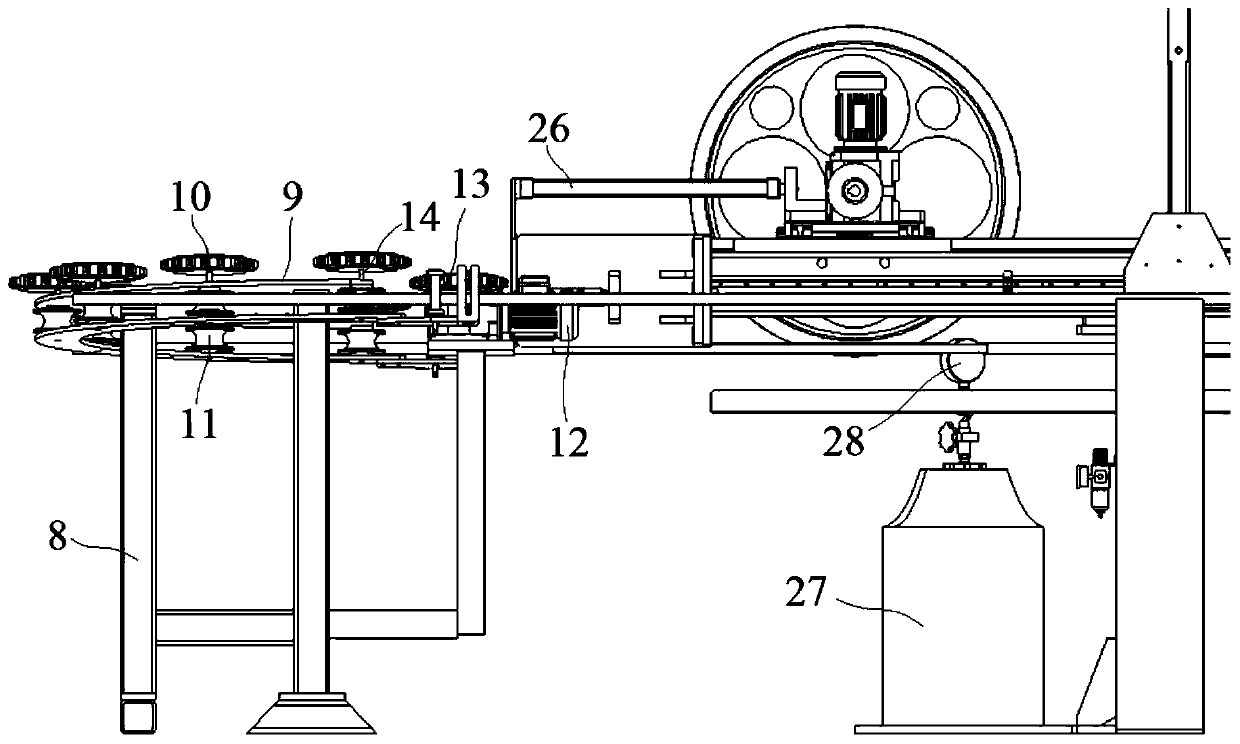

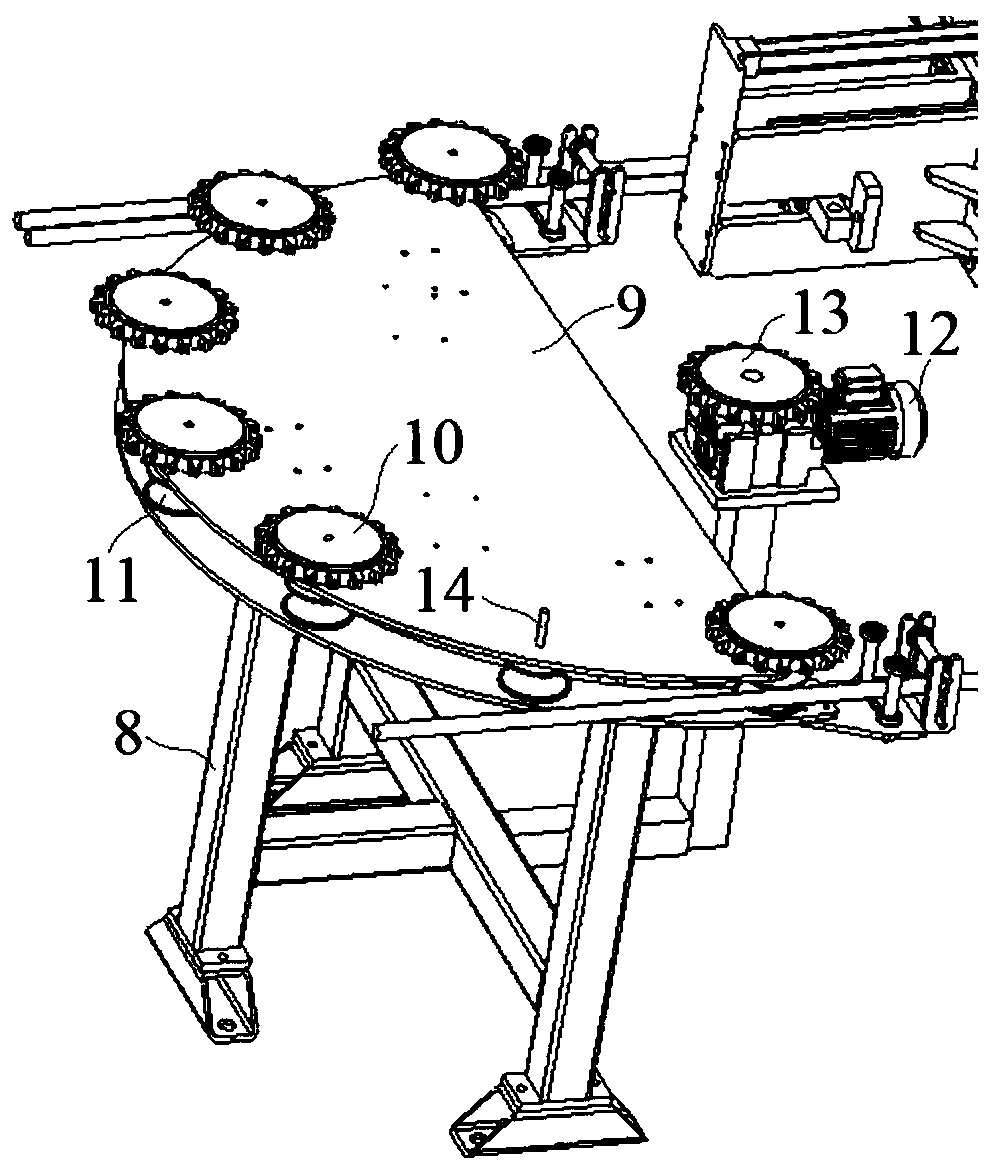

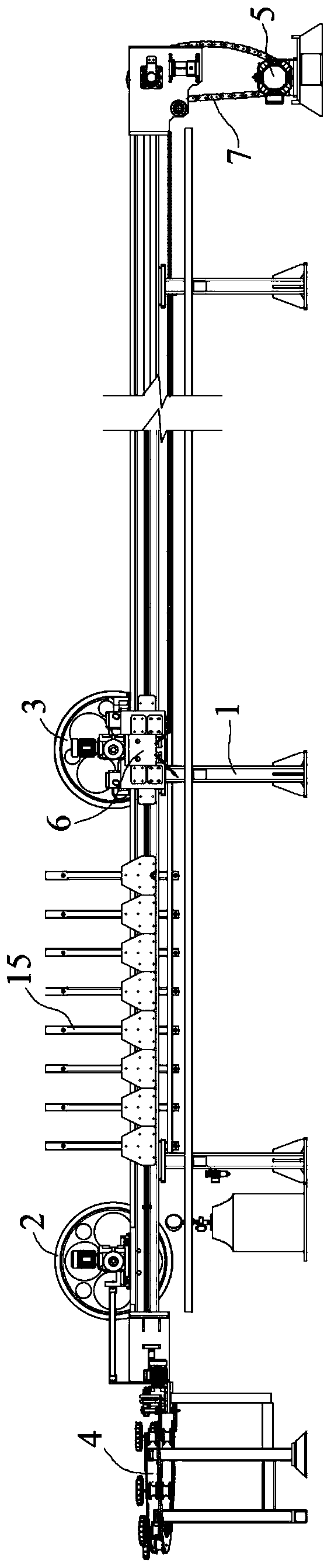

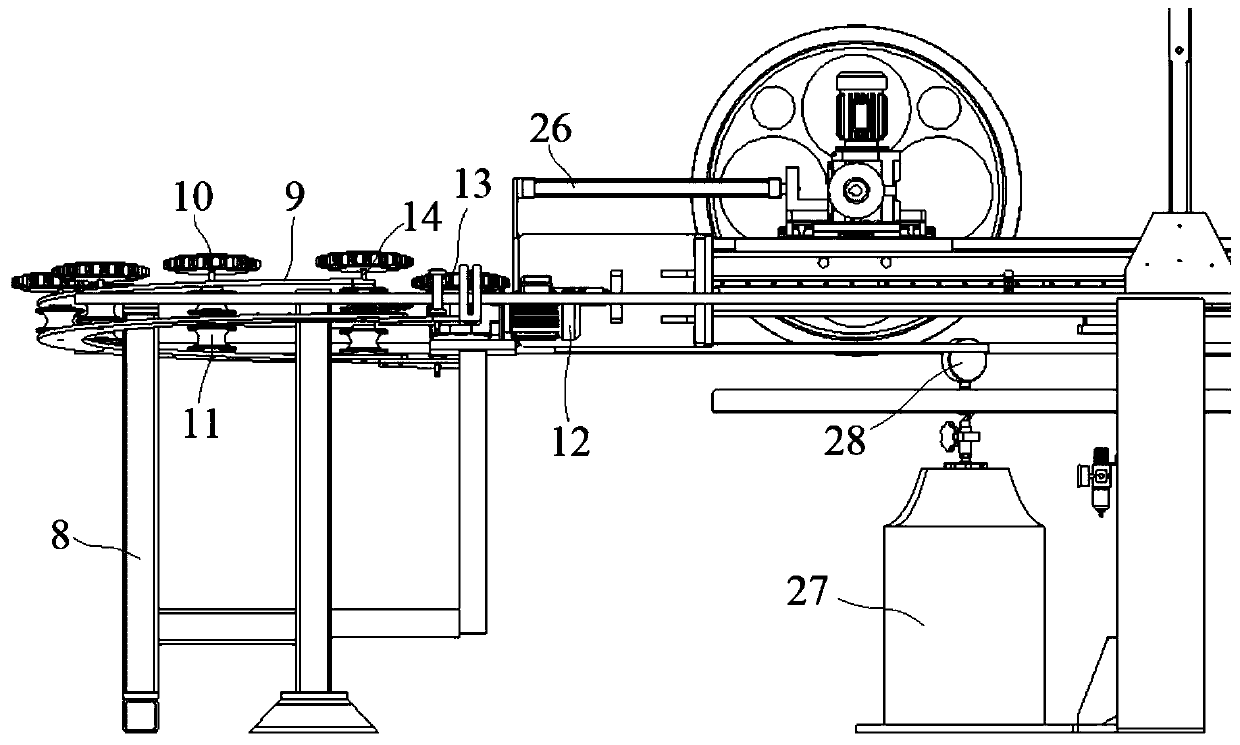

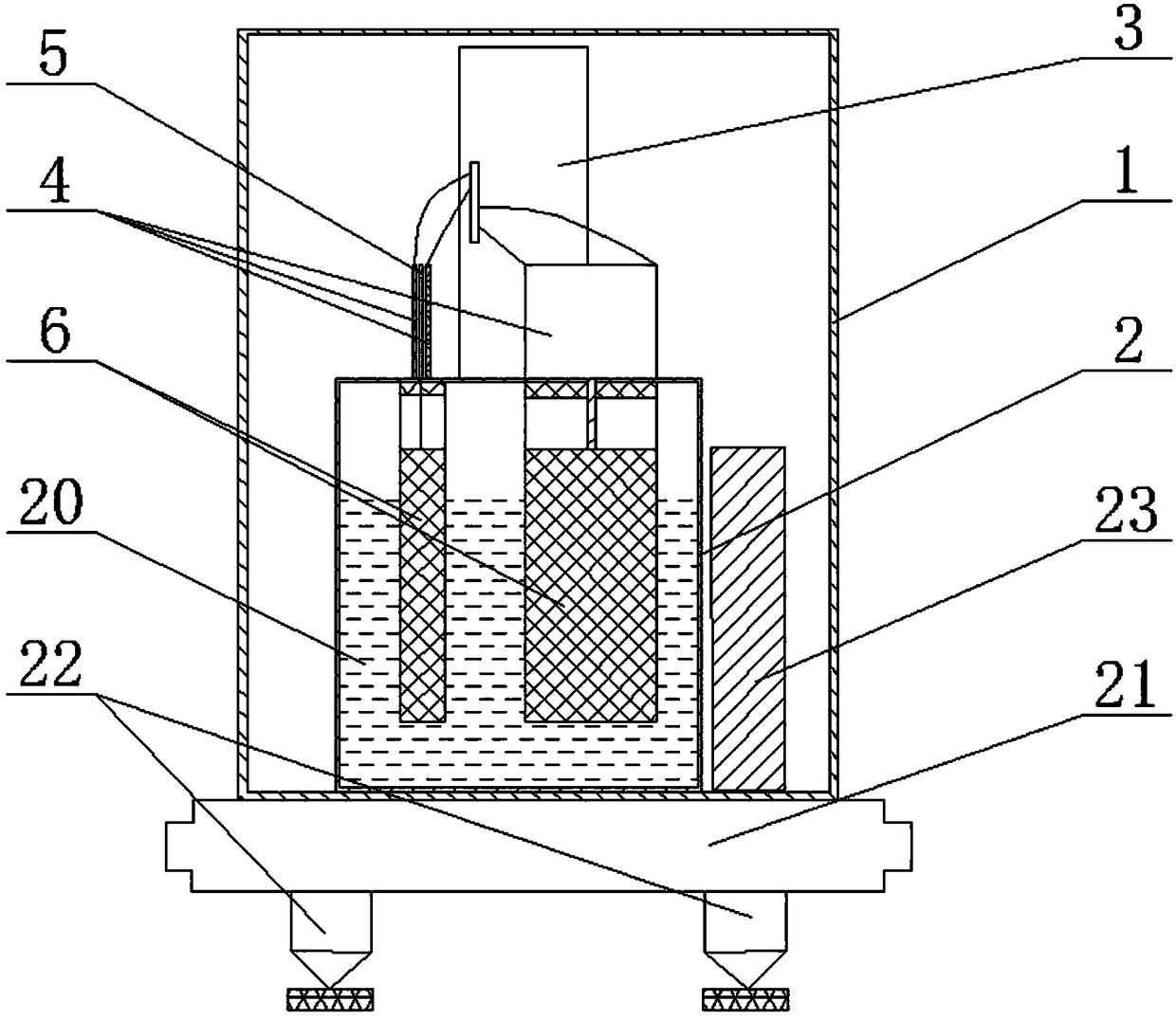

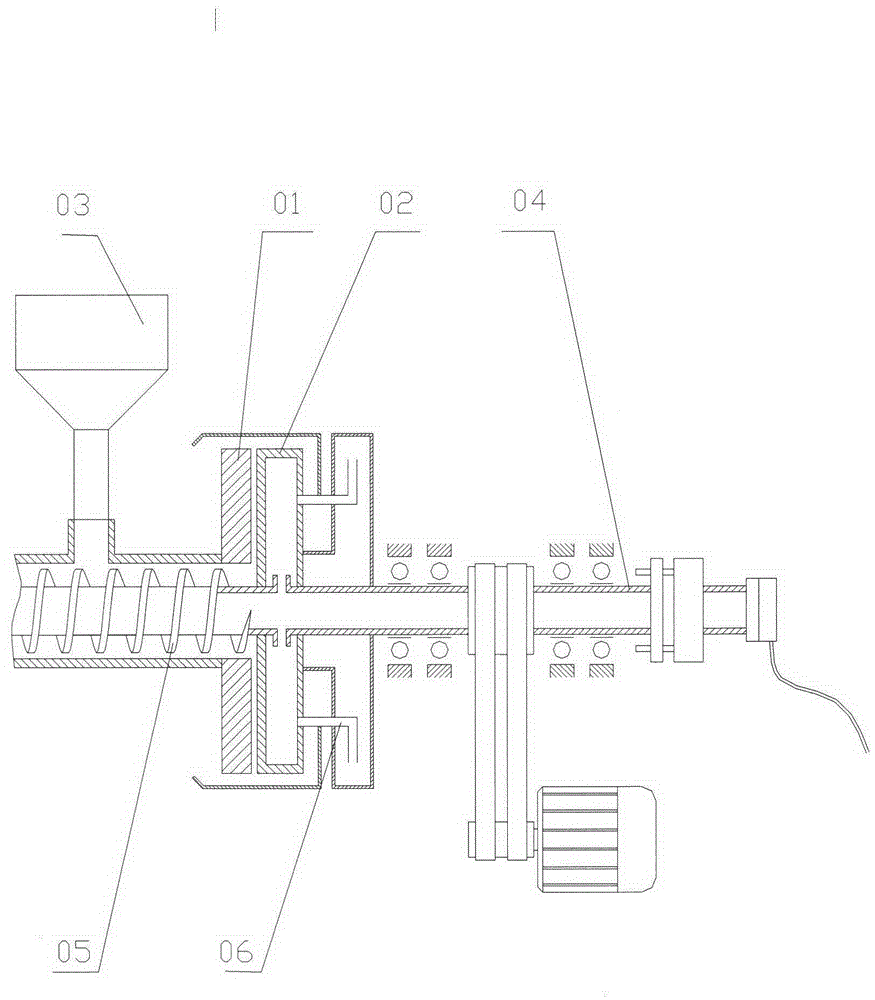

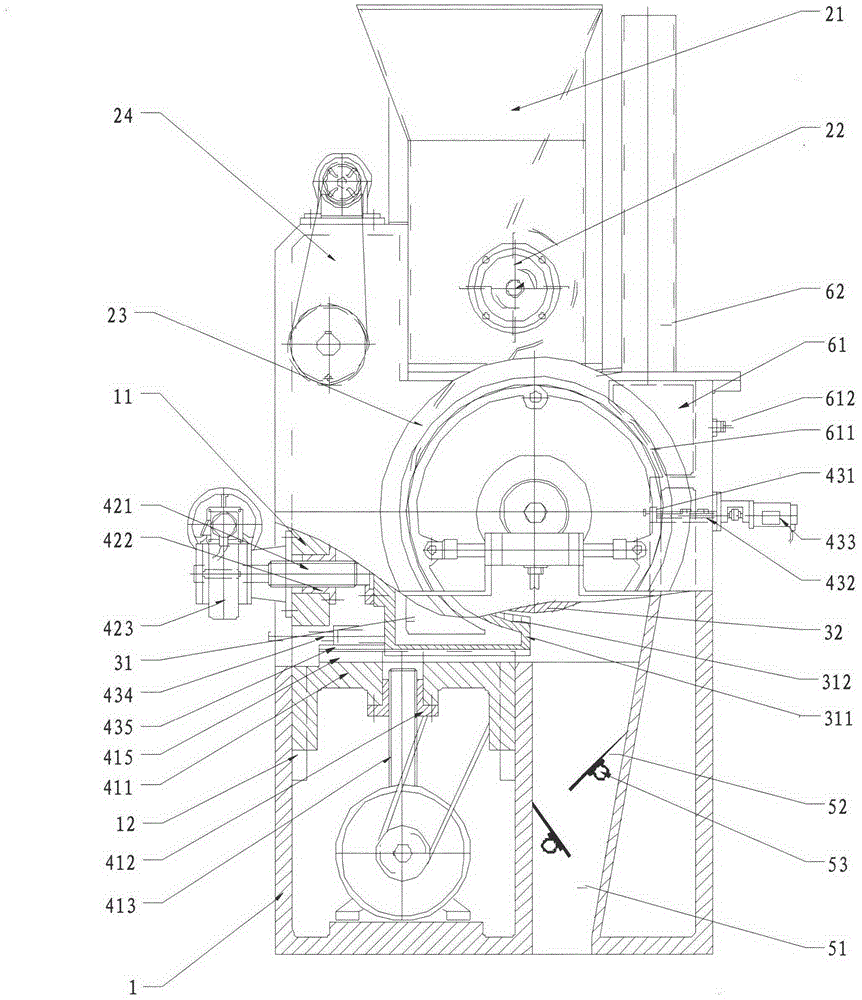

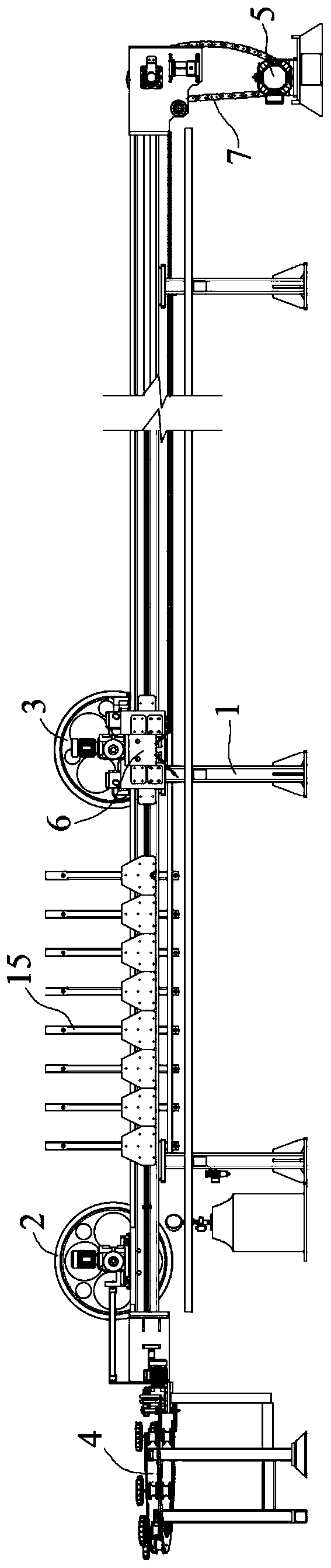

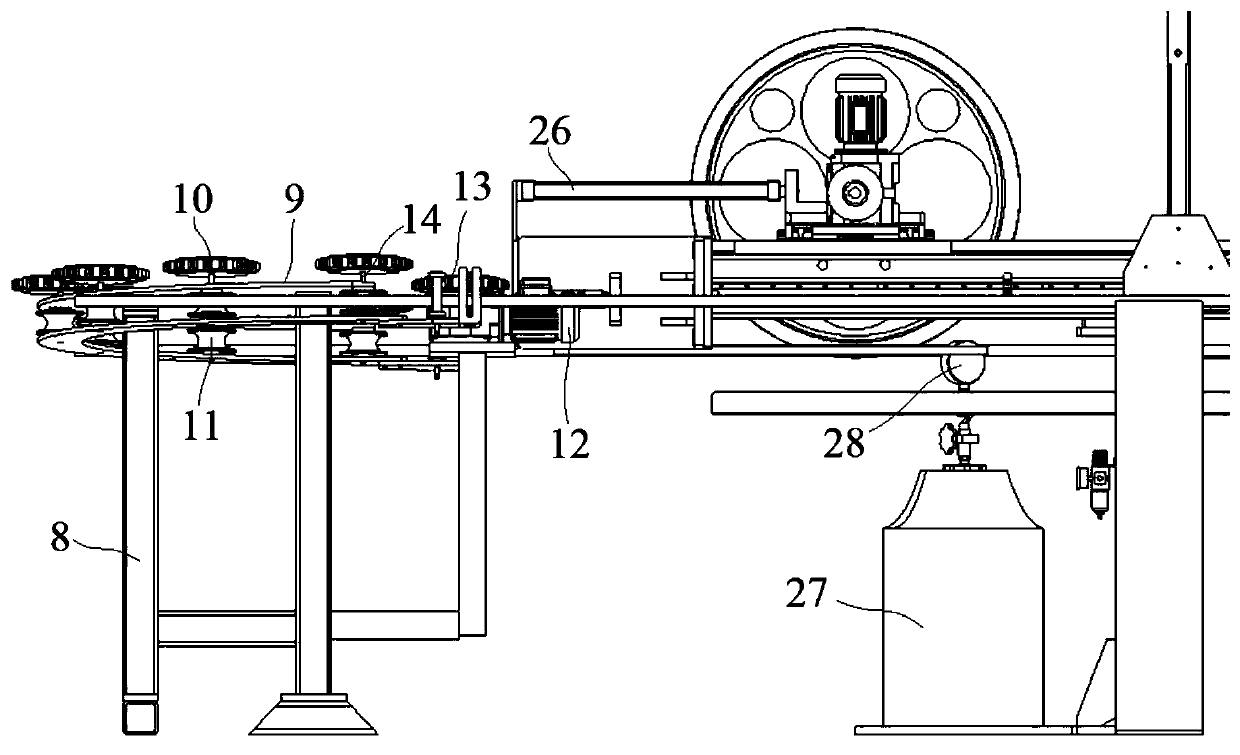

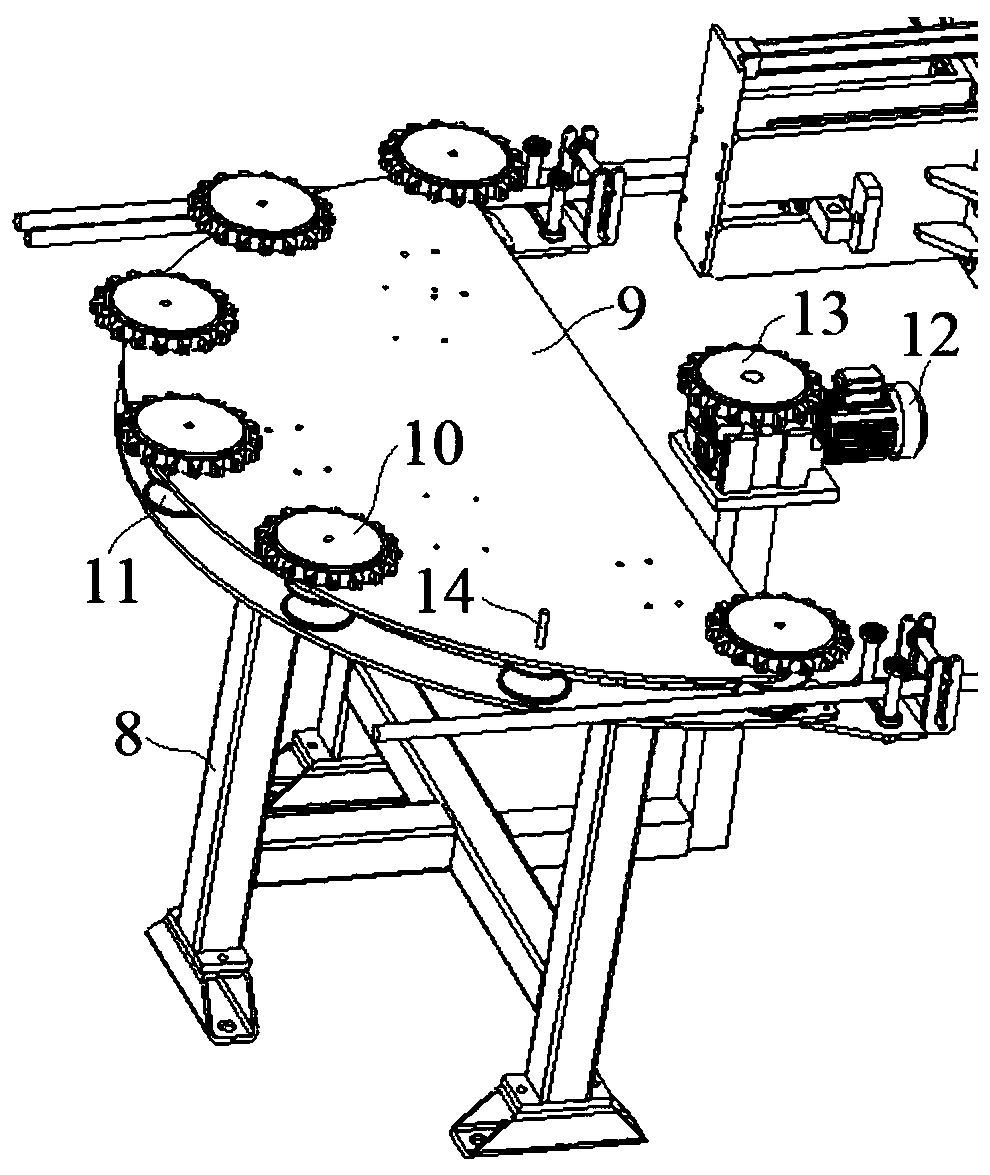

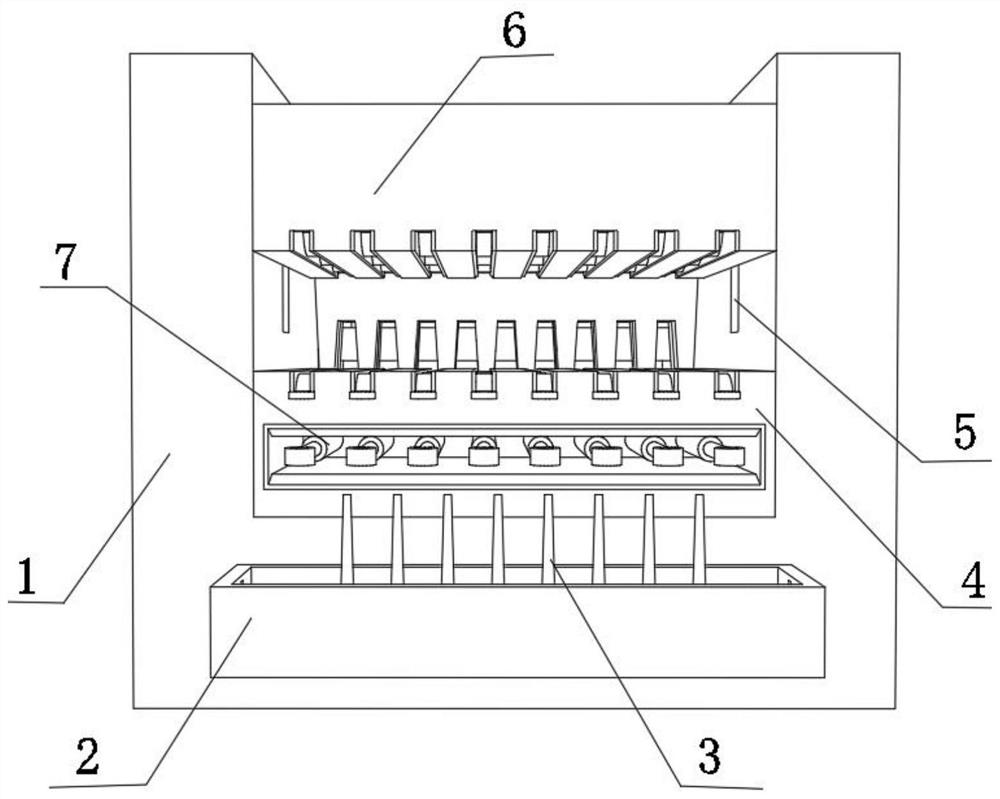

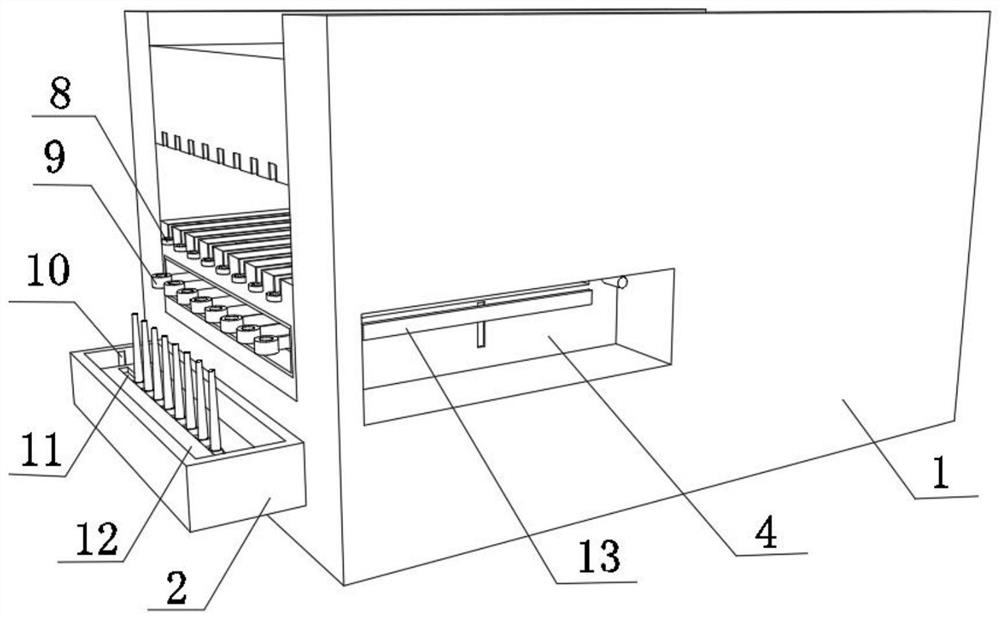

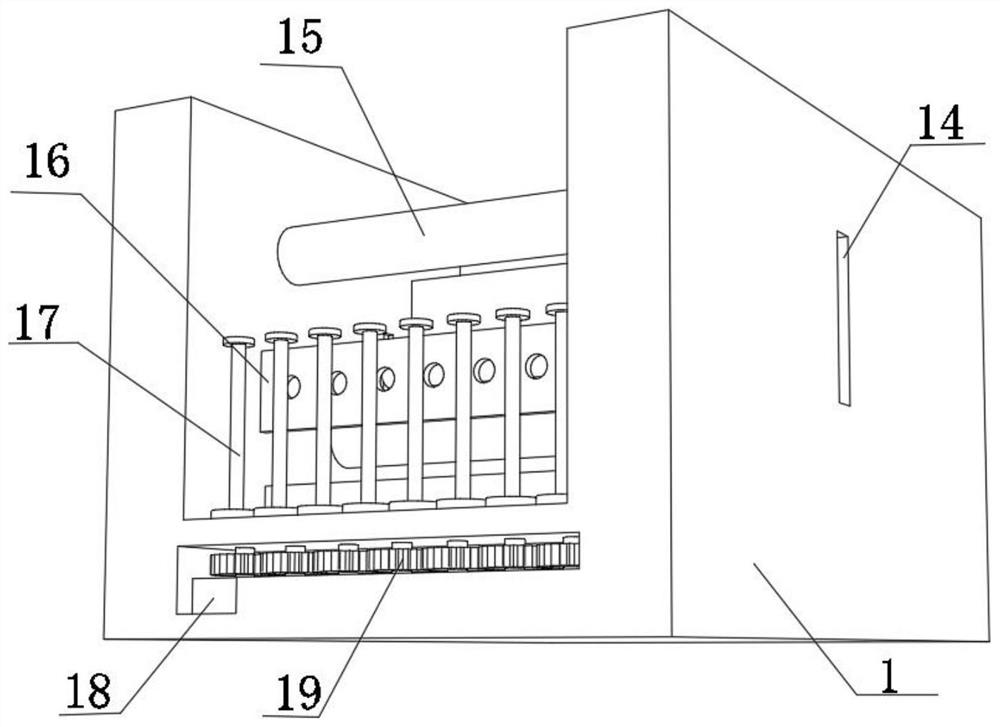

High-efficiency and energy-saving material grinder

ActiveCN103182338AEvenly take turns feedingBurn out preventionGrain treatmentsEngineeringEnergy analysis

The invention discloses a high-efficiency and energy-saving material grinder which comprises a rack, a feeding mechanism, a cutter component, a cutter adjusting device, a discharging device and an air cooling device. The feeding mechanism comprises a storage bin, a uniform feeder, a pusher plate and a stepping drive component for driving the uniform feeder and the pusher plate to move materials intermittently. The cutter component comprises a fixed cutter bed and a movable cutter drum, which have arc-shaped parallel working surfaces and are coaxial to each other. The cutter adjusting device comprises a gap measurement and control component, a horizontal adjustment mechanism and a vertical adjustment mechanism; the horizontal adjustment mechanism and the vertical adjustment mechanism are connected with the fixed cutter bed and push the fixed cutter bed to move; and the gap measurement and control component dynamically measures the gap between the fixed cutter bed and the movable cutter drum and controls the motions of the horizontal adjustment mechanism and the vertical adjustment mechanism. The discharging device comprises a discharge passage, a discharge plate and a vibrator. The air cooling device comprises an arc-shaped guide jet device and an exhaust duct, the arc-shaped guide jet device is provided with an air inlet and a plurality of jet holes facing the working surface of the movable cutter drum. The material grinder has the advantages of high efficiency, low energy consumption, long cutter life and high product quality.

Owner:卢小平 +1

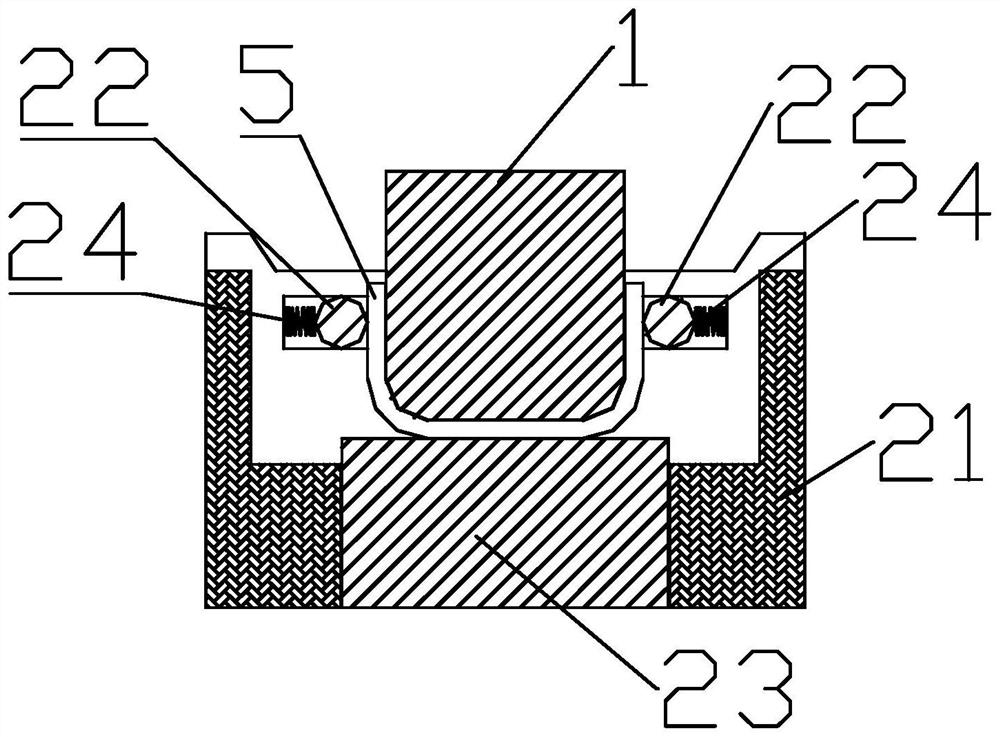

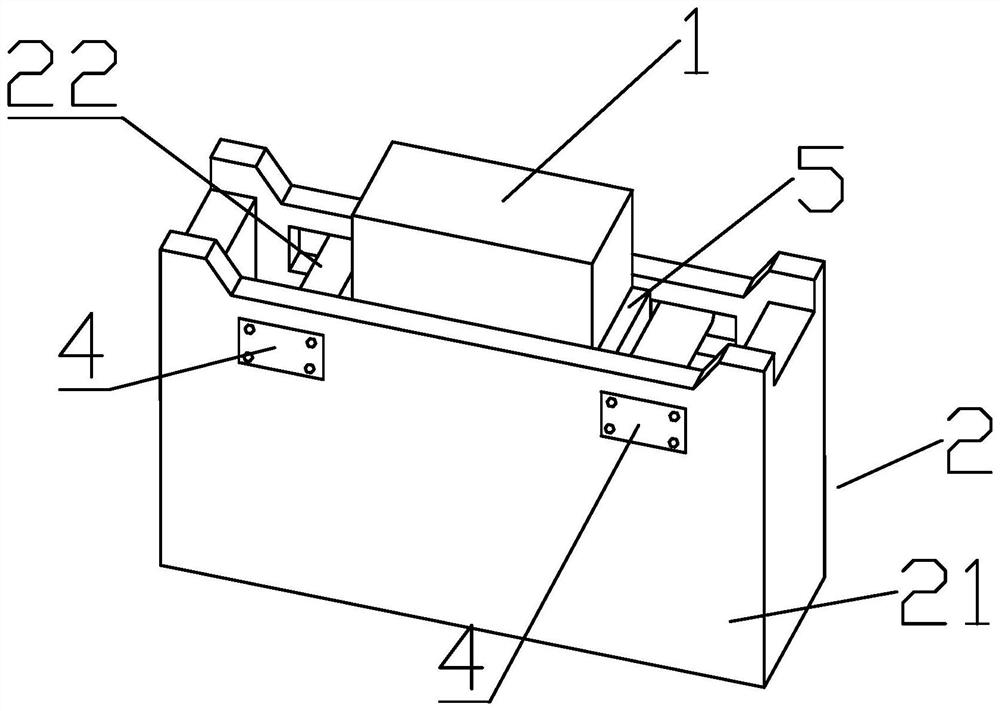

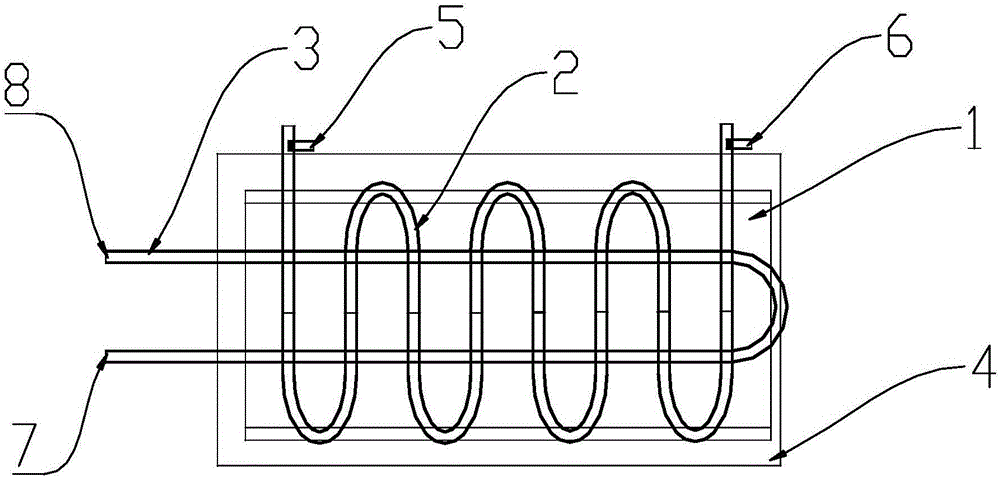

Manufacturing method of U-shaped spring for elevator security pincers

ActiveCN104493445AIncrease consumptionReduce utilizationFurnace typesHeat treatment furnacesSurface finishEngineering

The invention discloses a manufacturing method of a U-shaped spring for elevator security pincers. The manufacturing method is that a spring steel bar is heated through a heating die applied to an induction furnace, and the U-shaped spring is formed under oil pressure effect through a forming oil pressure device for the U-shaped spring. The manufacturing method comprises the steps of (1) blanking, namely, processing bar steel into a spring steel bar with the specified length through a blanking machine; (2) heating the spring steel bar, namely heating the spring steel bar through the heating die applied to the induction furnace; (3) forming the U-shaped spring, namely, forming under the oil pressure through the forming oil pressure device for the U-shaped spring; (4) vibrating and chamfering, namely, vibrating the pressed and formed U-shaped spring through a grinding vibration machine together with grinding materials; (5) milling; (6) thermally processing the U-shaped spring, quenching and tempering; (7) performing surface finish. The U-shaped spring manufactured by the method has the advantages that decarburized layers of the spring are minimized, the oxidizing rate is low, the consistency of the mechanical properties is high, the service life is long, the spring is difficulty clamped on the forming die during discharging, and the manufacturing is energy saving and environmentally friendly.

Owner:上海核工碟形弹簧制造有限公司

Flexible yarn clearing device for yarn spooling processing

The invention discloses a flexible yarn clearing device for yarn spooling processing, and relates to the technical field of yarn spooling production and manufacturing. The problem of poor cleaning quality is solved. The flexible yarn clearing device specifically comprises a machine body, wherein first electric sliding grooves are formed in the inner walls of the opposite sides of the machine bodycorrespondingly, and the inner walls of the two first electric sliding grooves are provided with a same upper die base. A lower die base is arranged on the outer wall of the top of the machine body, the outer wall of the top of the lower die base and the outer wall of the bottom of the upper die base are each provided with four or more lead grooves, the inner walls of the four or more lead groovesare each of a wavy structure, and the lower die base and the upper die base are matched. The inner walls of the opposite sides of the four or more lead grooves located in the lower die base and the four or more lead grooves located in the upper die base are each provided with a protective layer in an adhesive mode. According to the flexible yarn clearing device, sponge is wetted by water in a water tank, and a rotating roller on the lower die base is wetted by the sponge when rotating, so that yarns are wetted when making contact with the rotating roller during conveying, friction static electricity of the yarns is eliminated, impurities are prevented from being adsorbed in the later period, and the cleaning quality is guaranteed.

Owner:衡阳新新纺织机械有限公司

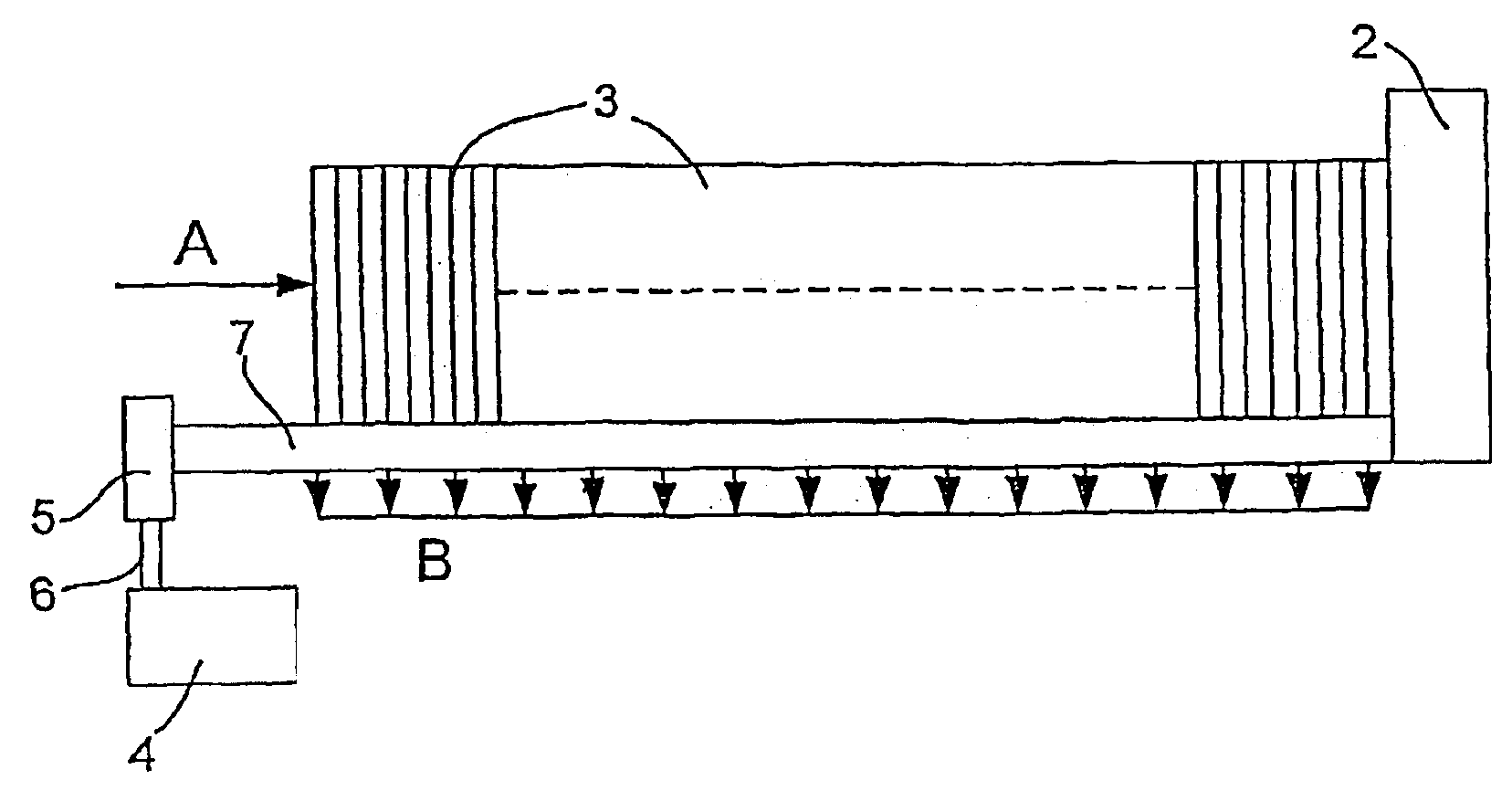

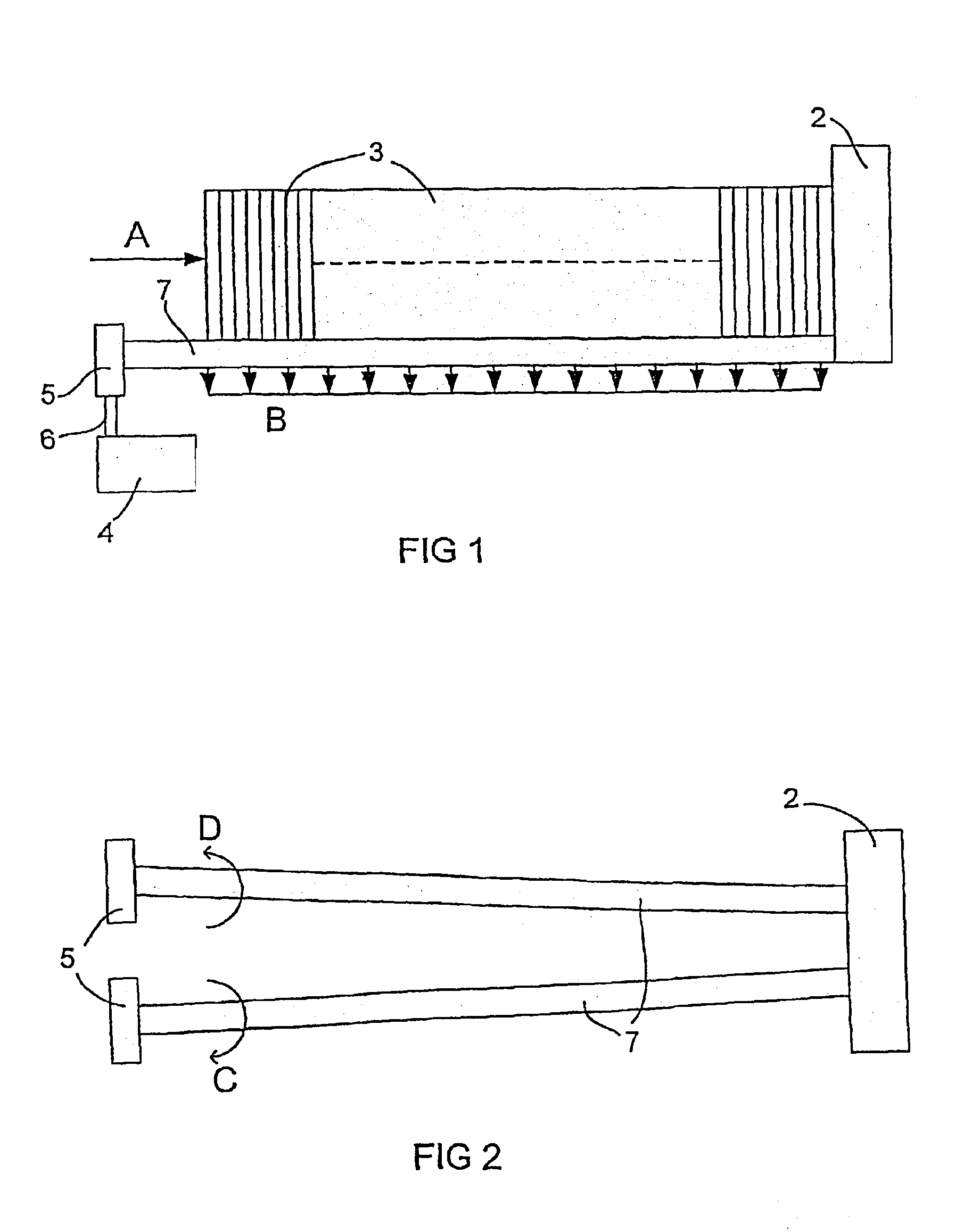

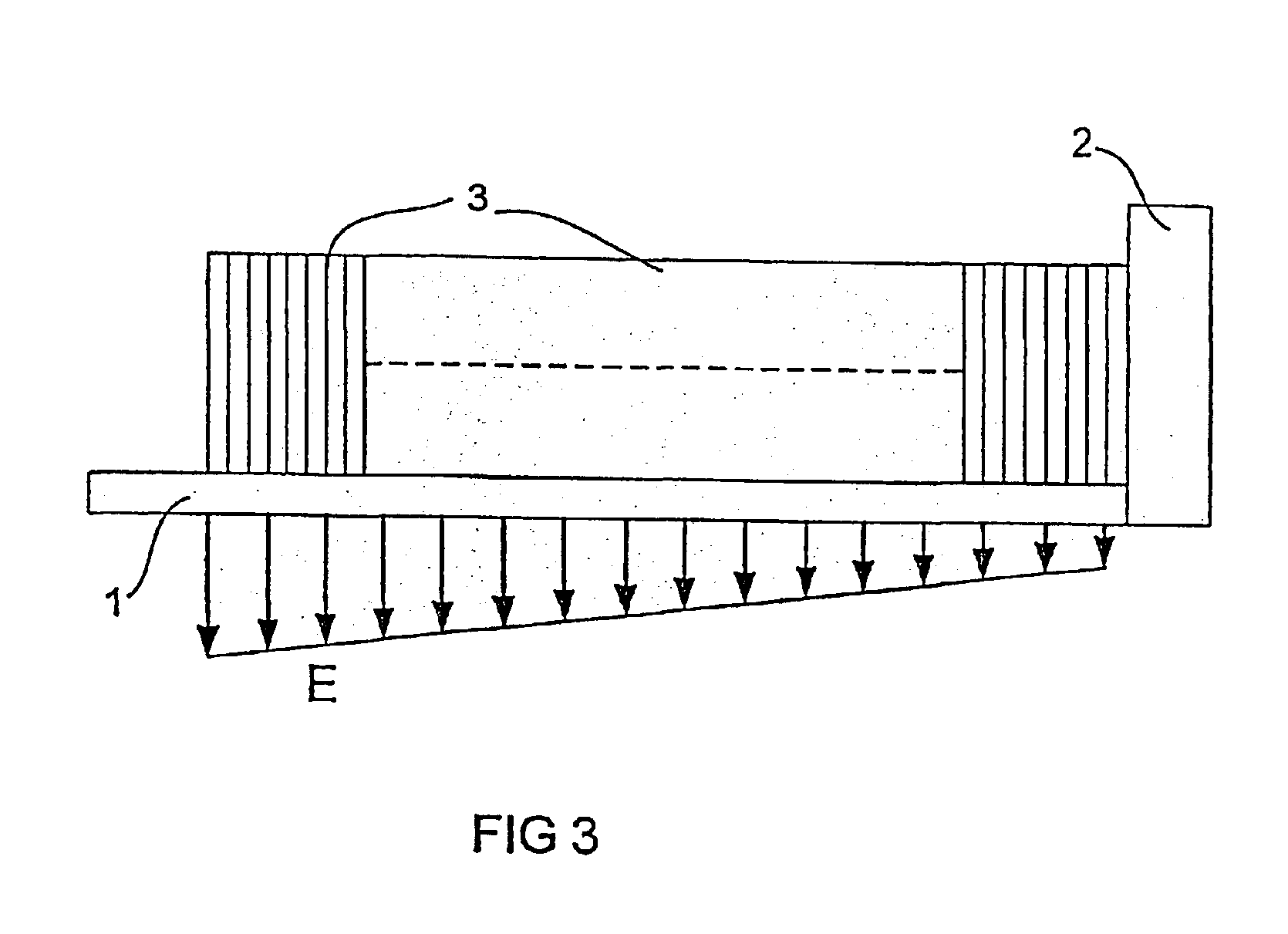

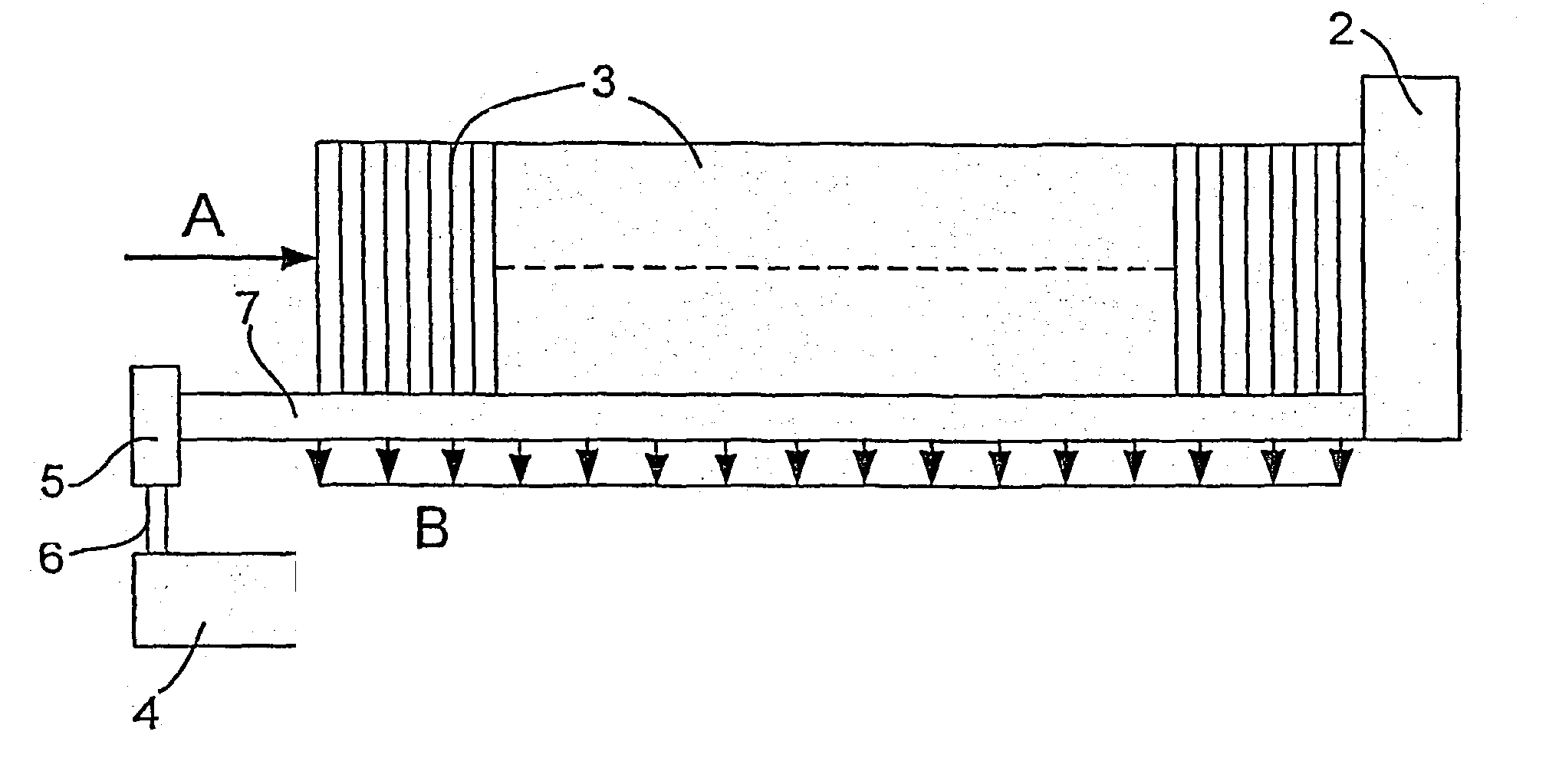

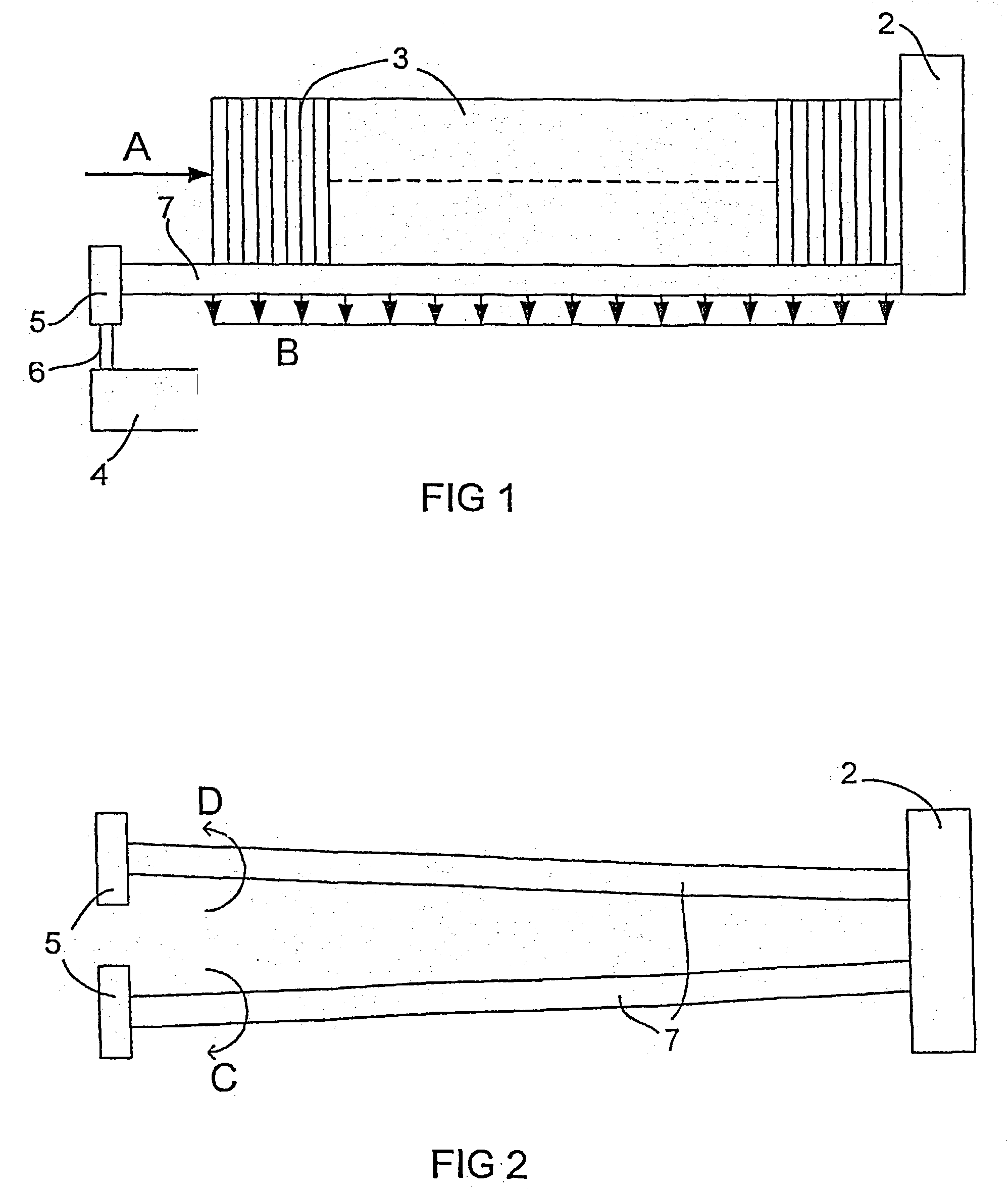

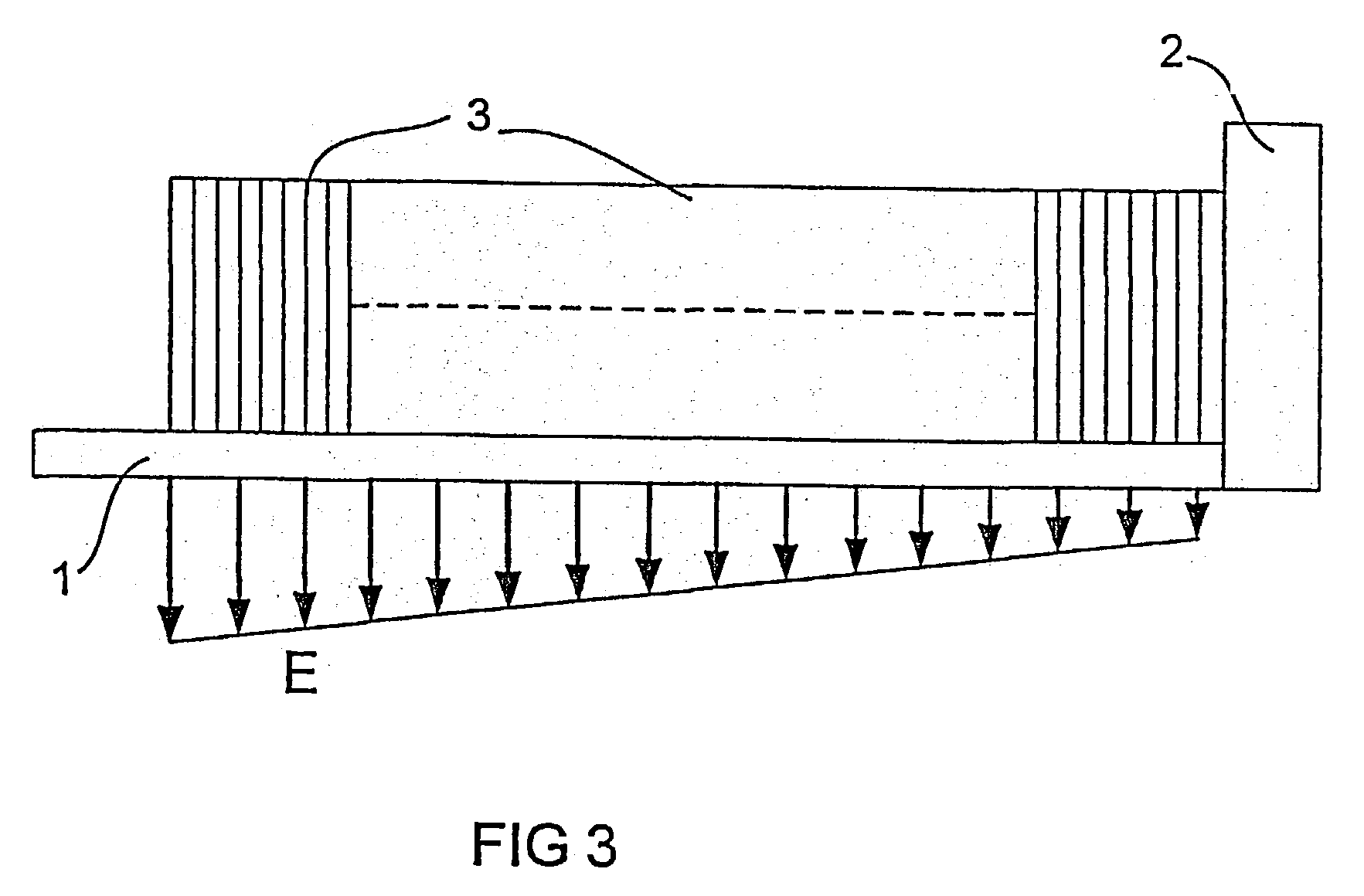

Device and a method for feeding packaging blanks

InactiveUS20030173732A1Eliminate static frictionPackagingArticle separationFeeding forceStatic friction

A device for feeding packaging blanks (3) to a packaging machine has a magazine with two shafts (7) mounted at the bottom for supporting the blanks (3). The shafts (7) are brought to rotate at constant speed in opposite directions to each other, hence eliminating the static friction from the bottom of the magazine. An angle is formed between the shafts (7), so that a small, forwardly directed force component contributes to the movement of the blanks (3). The dynamic friction is used to move blanks (3) towards a gate (2) at the end of the magazine, and only a small, constant feeding force (A) from a pusher is necessary for the movement.

Owner:TETRA LAVAL HLDG & FINANCE SA

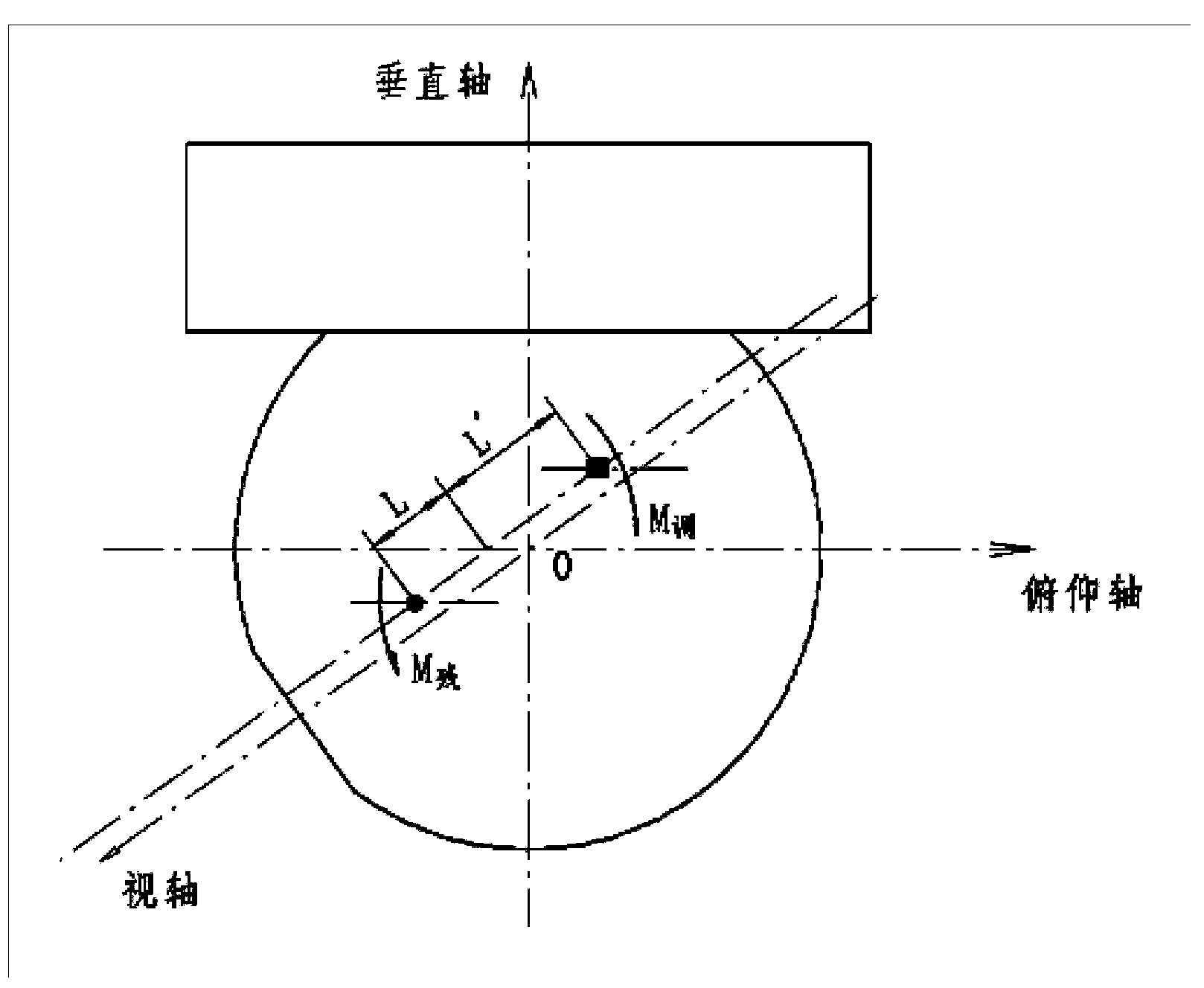

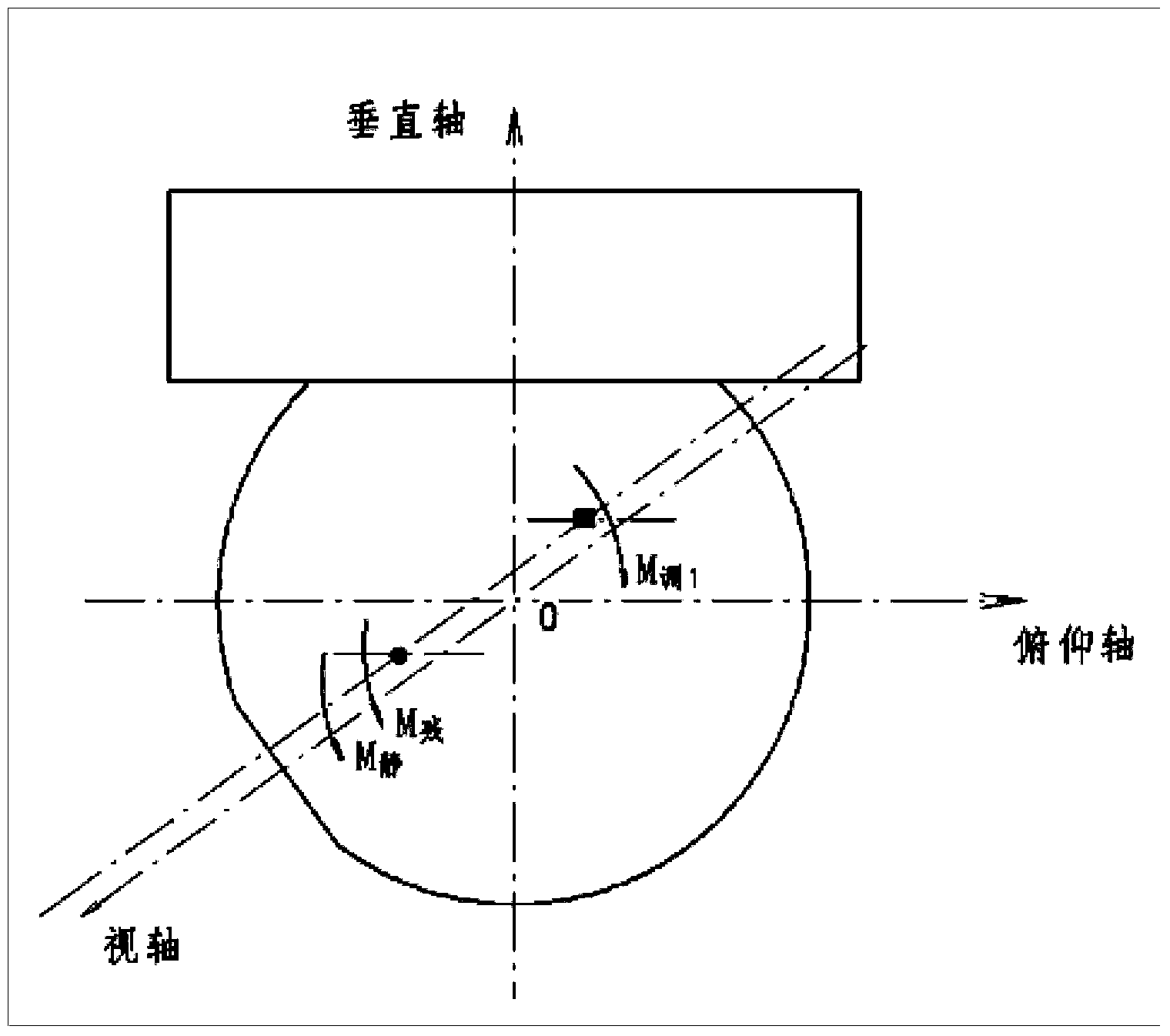

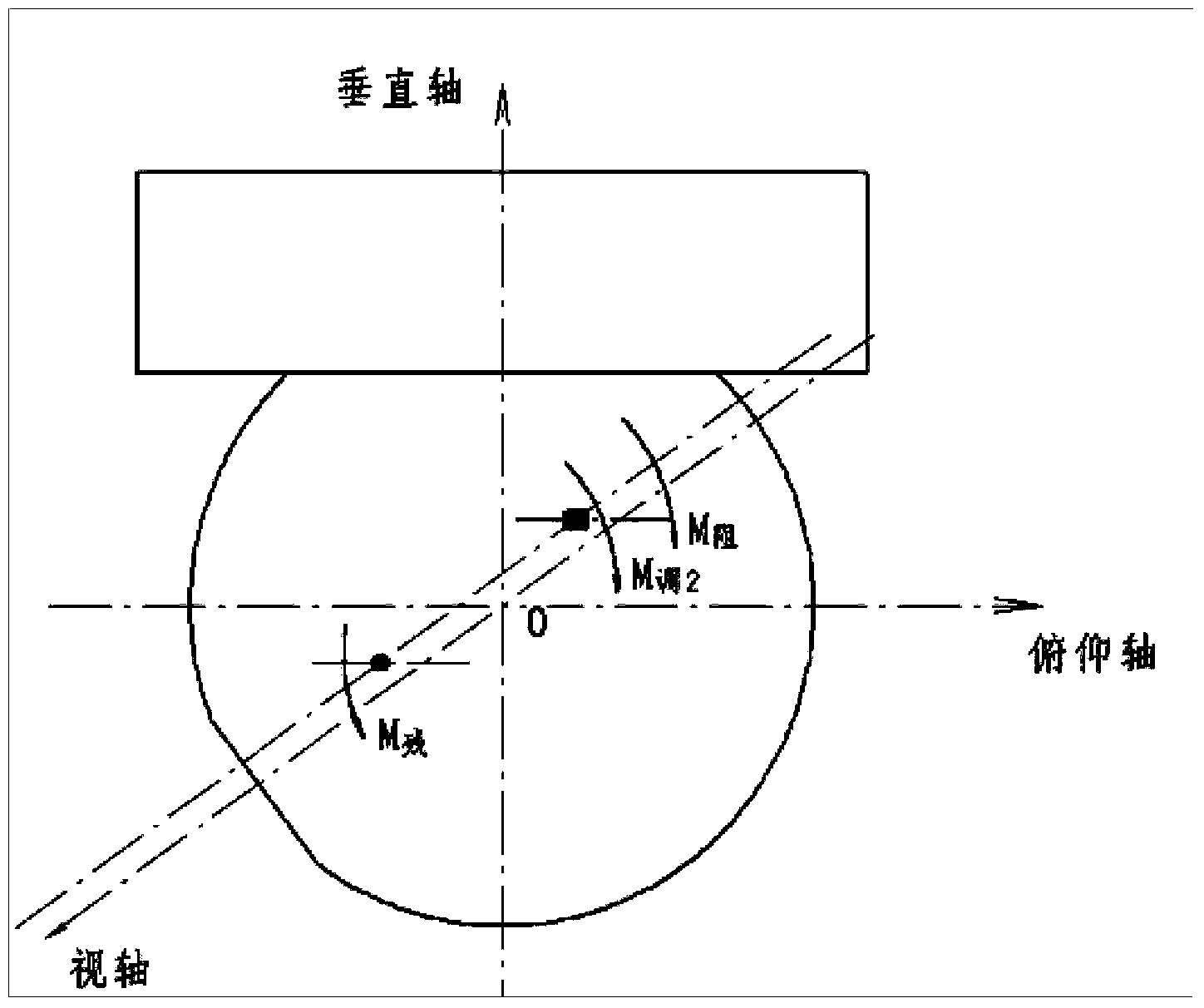

Method for improving photoelectric platform imaging quality through precision balancing

InactiveCN104320584AReduce or eliminate static frictionReduce or eliminate drag torqueTelevision system detailsCounterweightsImaging qualityLinear vibration

The invention provides a method for improving the photoelectric platform imaging quality through precision balancing, and belongs to the field of photoelectric technologies. To improve the channel for improving the balancing precision of a photoelectric platform, the method includes the steps that 1, after the photoelectric platform is installed, a servo drive motor is removed; 2, the bearing pretightening force is lowered, and a bearing is cleaned; 3, various wires of the effective load are removed, and the resisting moment generated between the effective load and an outer frame due to wire drag is prevented effectively; 4, balancing is conducted through a traditional method of centroid balancing introduced in a background technology; 5, the bearing pretightening force is added, the servo drive motor is installed, various wires are inserted and bounded, and precision balancing is finished. By means of the method, balancing resistance moment brought out by various friction force and wire drag is eliminated, compared with a conventional balancing method, the balancing accuracy is improved, the possibility that linear vibration of the photoelectric platform is converted into angular vibration is lowered, the visual axis stabilization accuracy of the photoelectric platform is improved, and the imaging quality and operating range of the photoelectric platform are improved beneficially.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Method for improving mechanical property of ceramic polymer composite material

ActiveCN113149514AImprove mechanical propertiesImprove thermal performanceStatic frictionMechanical property

The invention provides a method for improving the mechanical property of a ceramic polymer composite material, and the method comprises the following steps: carrying out plasticizing molding on corundum-type alumina particles and PPS engineering resin to obtain a composite material blank, and carrying out heat treatment to obtain the ceramic polymer composite material. The invention provides a material heat treatment method which is used for carrying out heat treatment on a high-strength ceramic polymer composite material containing ultrahigh-proportion ceramic powder and aims at eliminating static friction force and static pressure stored in the material forming process. The material has the advantages of ceramic and high polymer materials, has the characteristics of good mechanical strength, high thermal conductivity, good high temperature resistance, excellent processability and the like, and is very suitable for being applied to power PCBs (Printed Circuit Boards).

Owner:广州青苗新材料科技有限公司

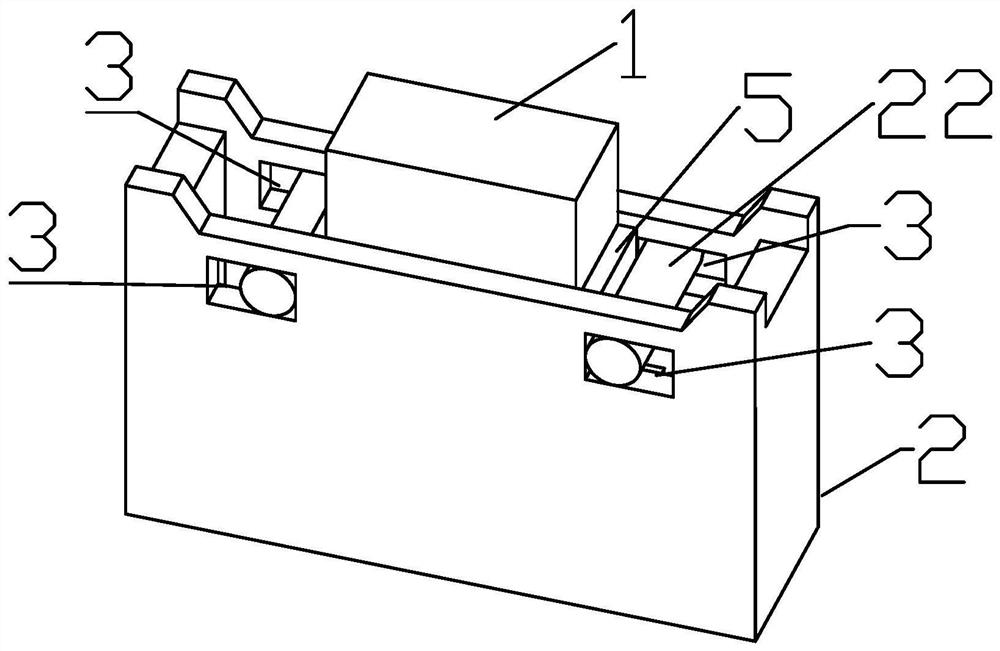

Loading and unloading tool kit for double-end stud

PendingCN114734411AAvoid getting stuckGood thread connection performanceMetal-working hand toolsNuclear energy generationHigh torqueStatic friction

An assembling and disassembling tool kit for a double-end stud is composed of an installing tool and a disassembling tool, the installing tool comprises three types, namely a low-torque installing tool, a medium-torque installing tool and a high-torque installing tool, and the disassembling tool is of a single type. After the double-end stud is mounted through the mounting tool, the static friction force between the mounting tool and the double-end stud can be quickly eliminated only by reversely screwing the mounting tool, so that the dynamic friction force between the mounting tool and the double-end stud is far lower than the static friction force between the double-end stud and a threaded hole of a workpiece; it is guaranteed that the installation tool can be rapidly withdrawn from the double-end stud, and the fastening end of the double-end stud and the installation tool are effectively prevented from being clamped. When the double-end stud is disassembled through the disassembling tool, the disassembling tool and the fastening end of the double-end stud can be screwed, meshed and fixed, the threaded structure of the fastening end of the double-end stud is effectively protected against damage in the disassembling process, and the disassembled double-end stud can maintain good threaded connection performance.

Owner:SHENYANG AEROSPACE UNIVERSITY

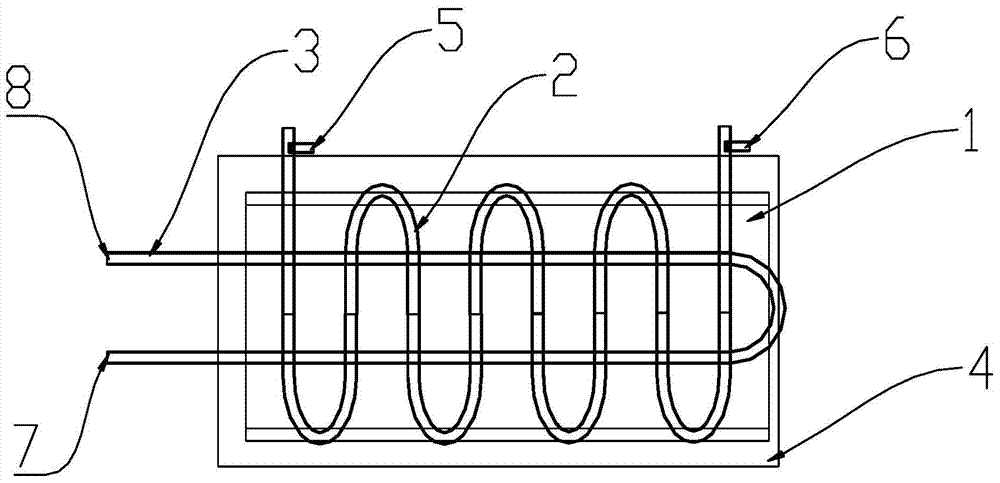

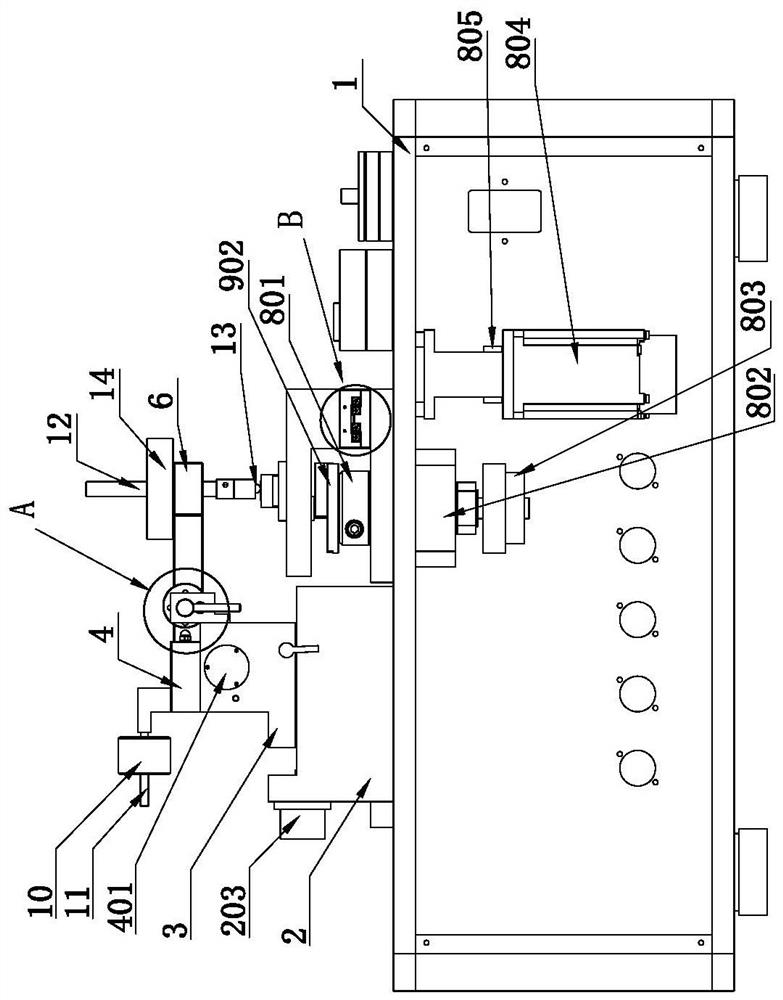

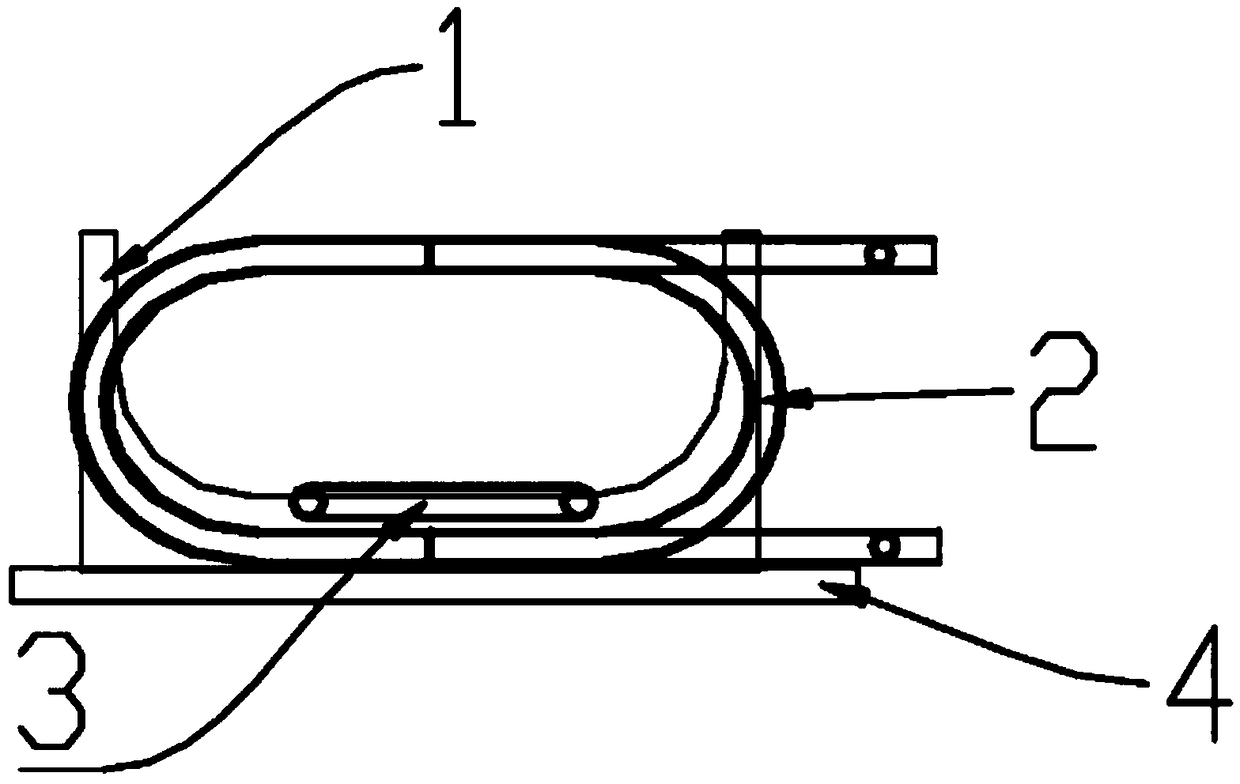

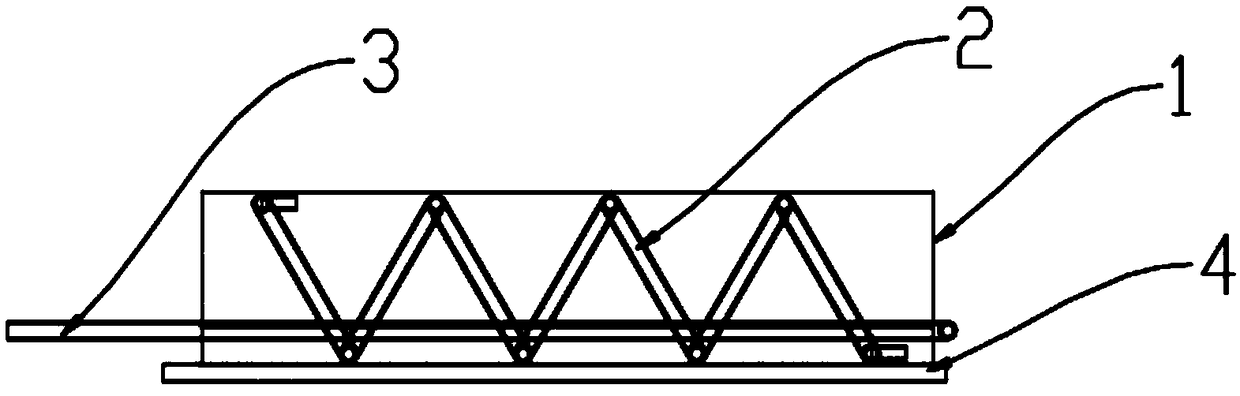

Storage device for optical fiber and cable processing

InactiveCN110104498AImprove production and processing efficiencyPlay the role of reversingFilament handlingSurge tankStatic friction

The invention discloses a storage device for optical fiber and cable processing. The storage device comprises a support, a first cable storage wheel set, a second cable storage wheel set, a guide mechanism and a driving mechanism. The first cable storage wheel set and the second cable storage wheel set are mounted on the support, and the guide mechanism is located at one end of the support. The driving mechanism is arranged at the other end of the support. A wheel disc is rotationally connected with a core shaft through at least one bearing. The first cable storage wheel set is mounted on thesupport through a mounting base, and at least one sliding rail is mounted at the position, below the mounting base, of the support. A sliding block for being embedded into the sliding rail is mountedon the lower surface of the mounting base. One side of the mounting base is connected with a piston rod of an air cylinder. A surge tank is connected with the air cylinder through a precision adjusting valve, and used for providing constant thrust for the air cylinder. According to the storage device, static friction force, generated when a cable generates lateral pressure on a guide wheel, between the guide wheel and a rotary shaft is eliminated, so that the cable passing through the guide wheel is kept at constant tension without being influenced by the guide wheel.

Owner:JIANGSU HENGTONG PHOTOELECTRIC

Multifunctional weight loading friction wear testing machine

PendingCN113686656AImprove detection accuracyEasy to useInvestigating abrasion/wear resistanceWear testingWorking environment

The invention provides a multifunctional weight loading friction wear testing machine in the technical field of mechanical detection, which comprises a test bed, a fixed seat arranged on the test bed, a movable seat arranged on the fixed seat and capable of moving in the left-right direction, a rotating seat connected to the movable seat and capable of rotating up and down, and a force sensor arranged in the rotating seat, the force sensor is provided with a force arm extending out of the rotating seat, the force arm is provided with a sample rod capable of moving up and down, the sample rod above the force arm can be sleeved with a plurality of weights, the sample rod below the force arm is provided with a ball head clamp, the rotating seat is provided with a balancing weight capable of moving in the left-right direction, and the rotating seat is arranged between the balancing weight and the force arm. An adjusting shaft is rotatably connected to the movable seat, an eccentric wheel is arranged on the adjusting shaft, a large-diameter section, a small-diameter section and two medium-diameter sections are arranged on the eccentric wheel, and a fixing rod is arranged on the rotating seat relative to the eccentric wheel; the machine is high in detection precision, convenient to use and capable of simulating friction wear tests in different working environments.

Owner:YANGZHOU UNIV

Constant tension cable storage system for optical fiber cable processing

InactiveCN110171741AImprove production and processing efficiencyPlay the role of reversingFilament handlingSurge tankSurface mounting

The invention discloses a constant tension cable storage system for optical fiber cable processing, which comprises a support, a first cable storage wheel set, a second cable storage wheel set, a guiding mechanism and a driving mechanism. The first cable storage wheel set and the second cable storage wheel set are arranged on the support, the guiding mechanism is located at one end of the support,and the driving mechanism is arranged at the other end of the support. The first cable storage wheel set and the second cable storage wheel set are each further provided with a mandrel and a plurality of wheel discs sleeving one end of the mandrel. The lower surface of the support is provided with a sliding block for insertion of a sliding rail. One side of the support is connected with a pistonrod of a cylinder, and a surge tank is connected to the cylinder through a precision pressure regulating valve so as to provide a constant thrust to the cylinder. The constant tension line storage system provides constant tension for the cable, thus not only preventing the cable from being broken due to excessive tension or being loosened due to lack of tension, but further ensuring that the tension of the cables during the storage process is always dynamically balanced to the optimal tension state. Accordingly, the stability of cable processing is guaranteed.

Owner:JIANGSU HENGTONG PHOTOELECTRIC

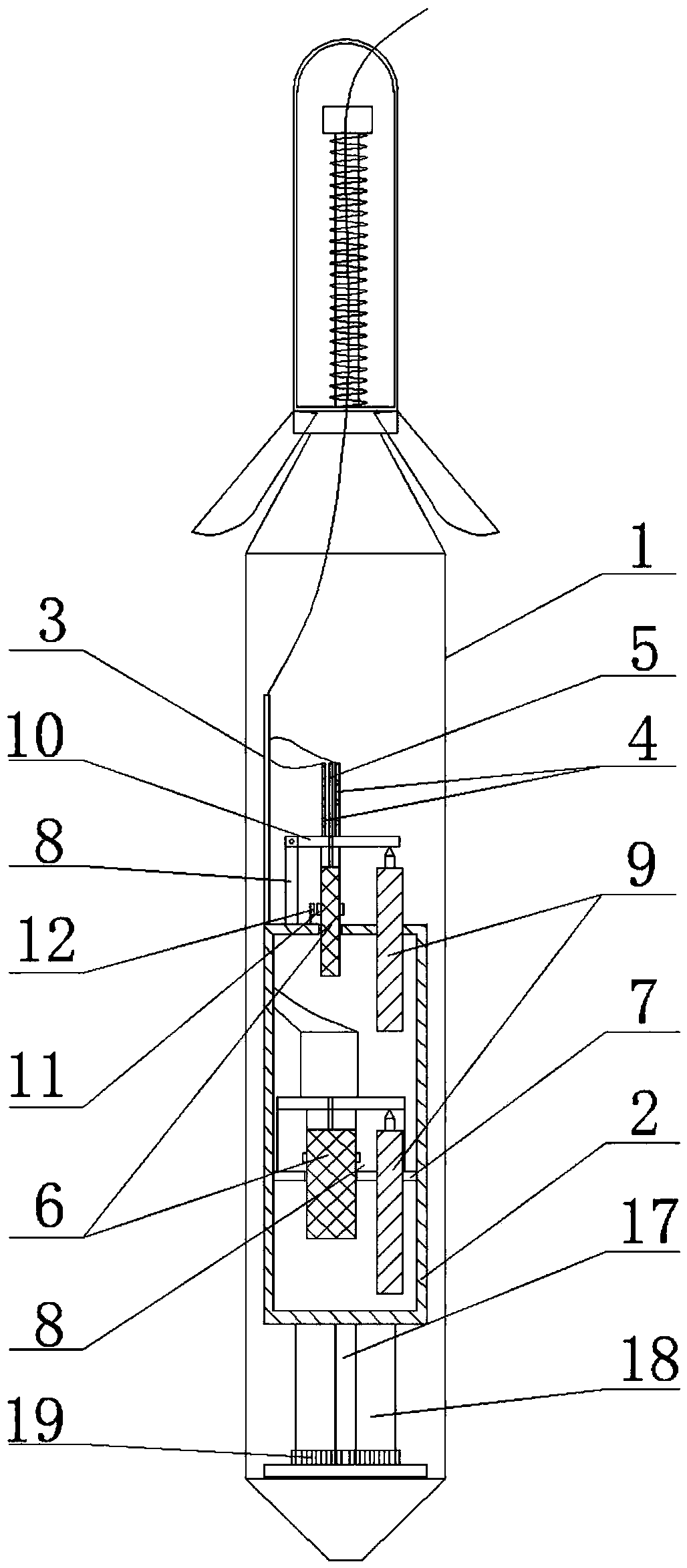

Tilt Monitoring Device

ActiveCN105823465BGuaranteed continuityEliminate static frictionIncline measurementElectricityEarth crust

The invention discloses a ground tilt monitoring device .The ground tilt monitoring device comprises a device shell, a suspension frame and a processing circuit board are arranged in the device shell, two capacitive sensors are orthogonally arranged on the suspension frame, each capacitive sensor comprises capacitor stators, capacitor rotors and pendulum bobs, the capacitor stators are arranged on the two sides of the capacitor rotors at equal intervals, the capacitor stators and the capacitor rotors are horizontally arranged on the same horizontal plane, the capacitor stators are arranged on the suspension frame, the pendulum bobs are arranged on the suspension frame in a hanging mode and arranged on the lower portions of the capacitor rotors to be in rigid connection with the capacitor motors, the capacitive sensors are electrically connected with the processing circuit board respectively, and a zero setting mechanism is further arranged on the suspension frame .According to the ground tilt monitoring device, when zero setting is conducted, the two capacitive sensors do not influence each other, the pendulum bobs drive the capacitor rotors to move to change the space between the capacitor rotors and the capacitor stators so as to produce capacitance variable quantity, and the influence of static friction force of pendulum bobs in the prior art is eliminated; the ground tilt monitoring device is mainly used for monitoring earth tides, earthquake precursors and tilting deformation of an earth crust, and the ground tilt monitoring device is simple in structure, good in stability, high in precision and high in output linearity.

Owner:吴清荣

Forming mold for U-shaped spring

PendingCN113617965AAvoid affecting product force performanceEliminate static frictionStructural engineeringMechanical engineering

Owner:上海核工碟形弹簧制造有限公司

A high-efficiency and energy-saving material pulverizer

The invention discloses a high-efficiency and energy-saving material grinder which comprises a rack, a feeding mechanism, a cutter component, a cutter adjusting device, a discharging device and an air cooling device. The feeding mechanism comprises a storage bin, a uniform feeder, a pusher plate and a stepping drive component for driving the uniform feeder and the pusher plate to move materials intermittently. The cutter component comprises a fixed cutter bed and a movable cutter drum, which have arc-shaped parallel working surfaces and are coaxial to each other. The cutter adjusting device comprises a gap measurement and control component, a horizontal adjustment mechanism and a vertical adjustment mechanism; the horizontal adjustment mechanism and the vertical adjustment mechanism are connected with the fixed cutter bed and push the fixed cutter bed to move; and the gap measurement and control component dynamically measures the gap between the fixed cutter bed and the movable cutter drum and controls the motions of the horizontal adjustment mechanism and the vertical adjustment mechanism. The discharging device comprises a discharge passage, a discharge plate and a vibrator. The air cooling device comprises an arc-shaped guide jet device and an exhaust duct, the arc-shaped guide jet device is provided with an air inlet and a plurality of jet holes facing the working surface of the movable cutter drum. The material grinder has the advantages of high efficiency, low energy consumption, long cutter life and high product quality.

Owner:卢小平 +1

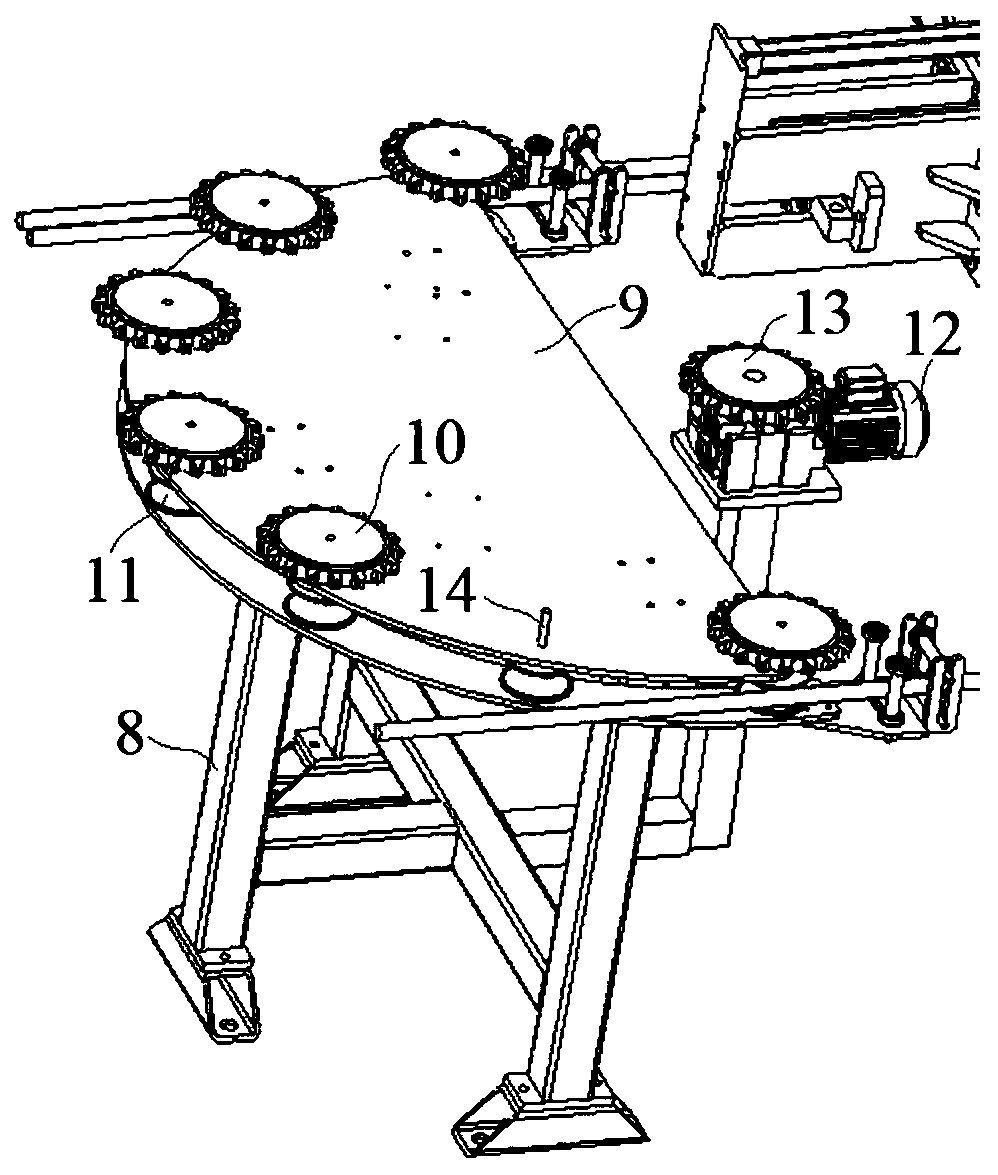

Micro-tension automatic wire storing device for processing optical fibers and cables

InactiveCN110171742AImprove production and processing efficiencyPlay the role of reversingFilament handlingStatic frictionEngineering

The invention discloses a micro-tension automatic wire storing device for processing optical fibers and cables. The micro-tension automatic wire storing device for processing the optical fibers and cables comprises a support, a first wire storing wheel group, a second wire storing wheel group, a guiding mechanism and a driving mechanism, wherein the first wire storing wheel group and the second wire storing wheel group are mounted on the support; the driving mechanism is arranged at the other end of the support; the second wire storing wheel group is movably mounted on the support by means ofa movable seat; the driving mechanism is connected with the movable seat by means of a chain; at least one sliding rail is mounted at the part, on the support, below a mounting seat; a sliding block allowing the sliding rails to be embedded therein is mounted on the lower surface of the mounting seat; one side of the mounting seat is connected with a piston rod of an air cylinder; and a pressure stabilizing tank is connected with the air cylinder by means of a precision pressure regulating valve, and is used for providing constant thrust for the air cylinder. The micro-tension automatic wire storing device for processing the optical fibers and cables eliminates the static friction force between wheel discs and core shafts when cables generate side pressure on the wheel discs, so that the cables passing through the wheel discs keep constant tension without being influenced by the wheel discs, and the cable processing stability is ensured.

Owner:JIANGSU HENGTONG PHOTOELECTRIC

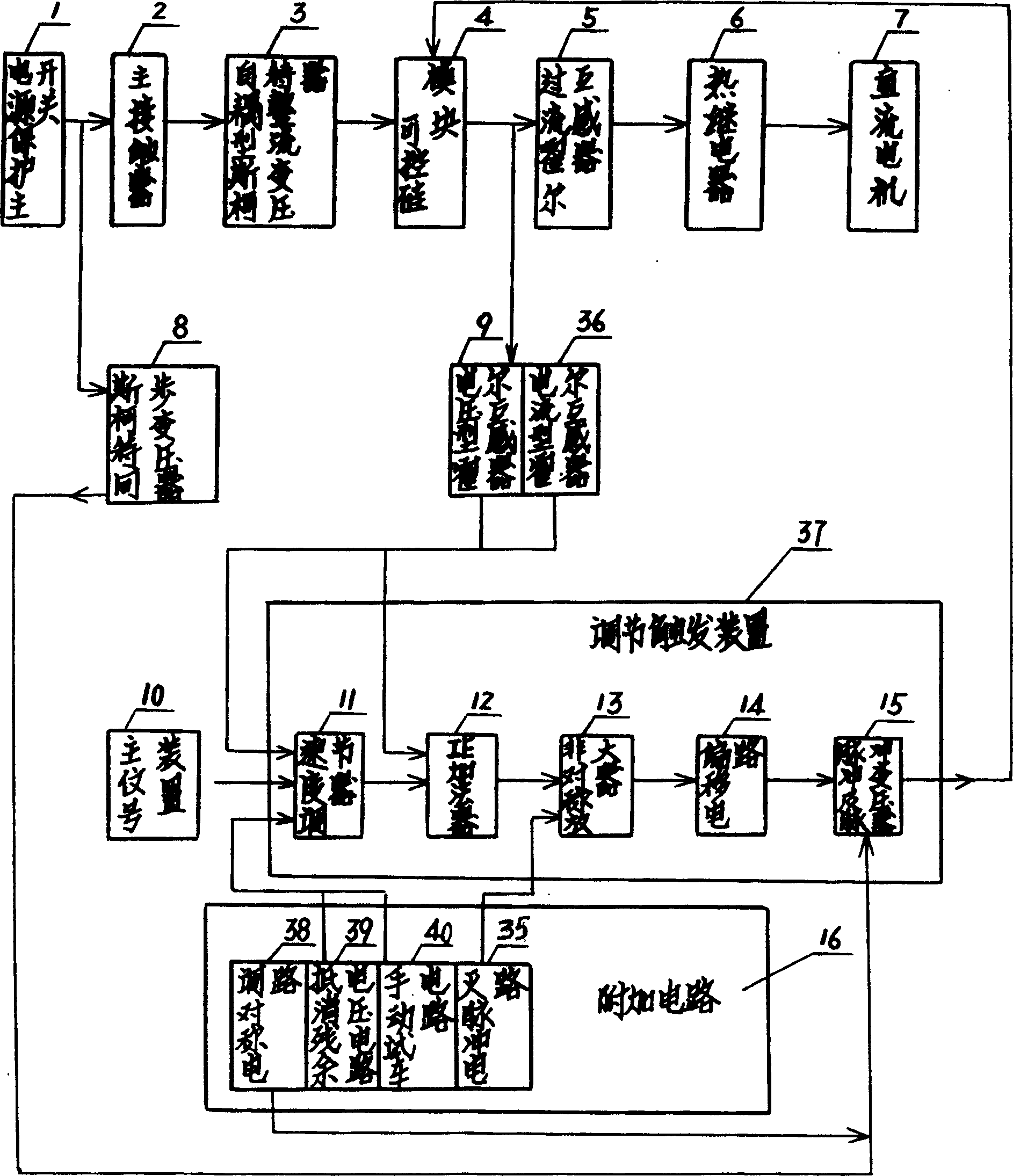

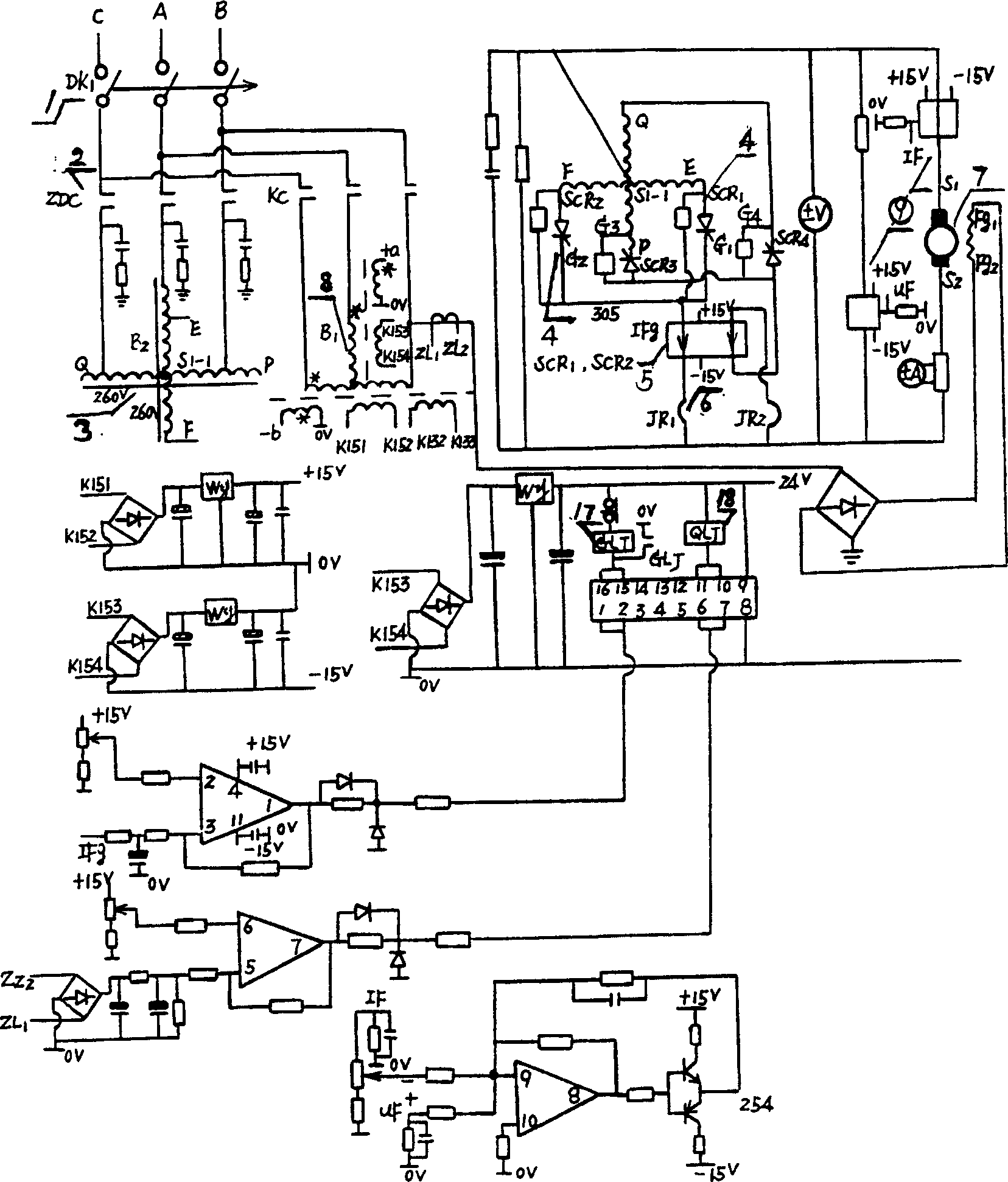

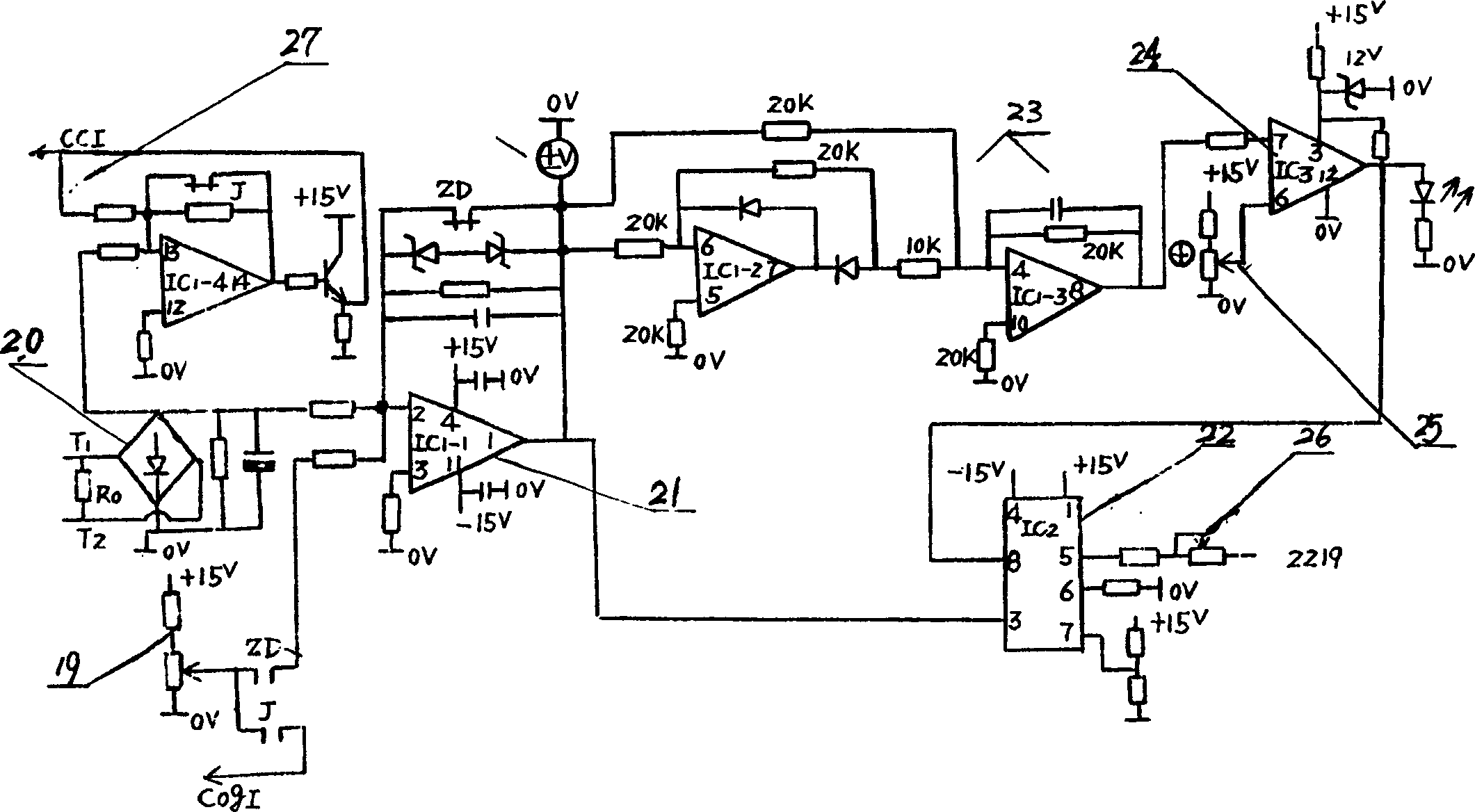

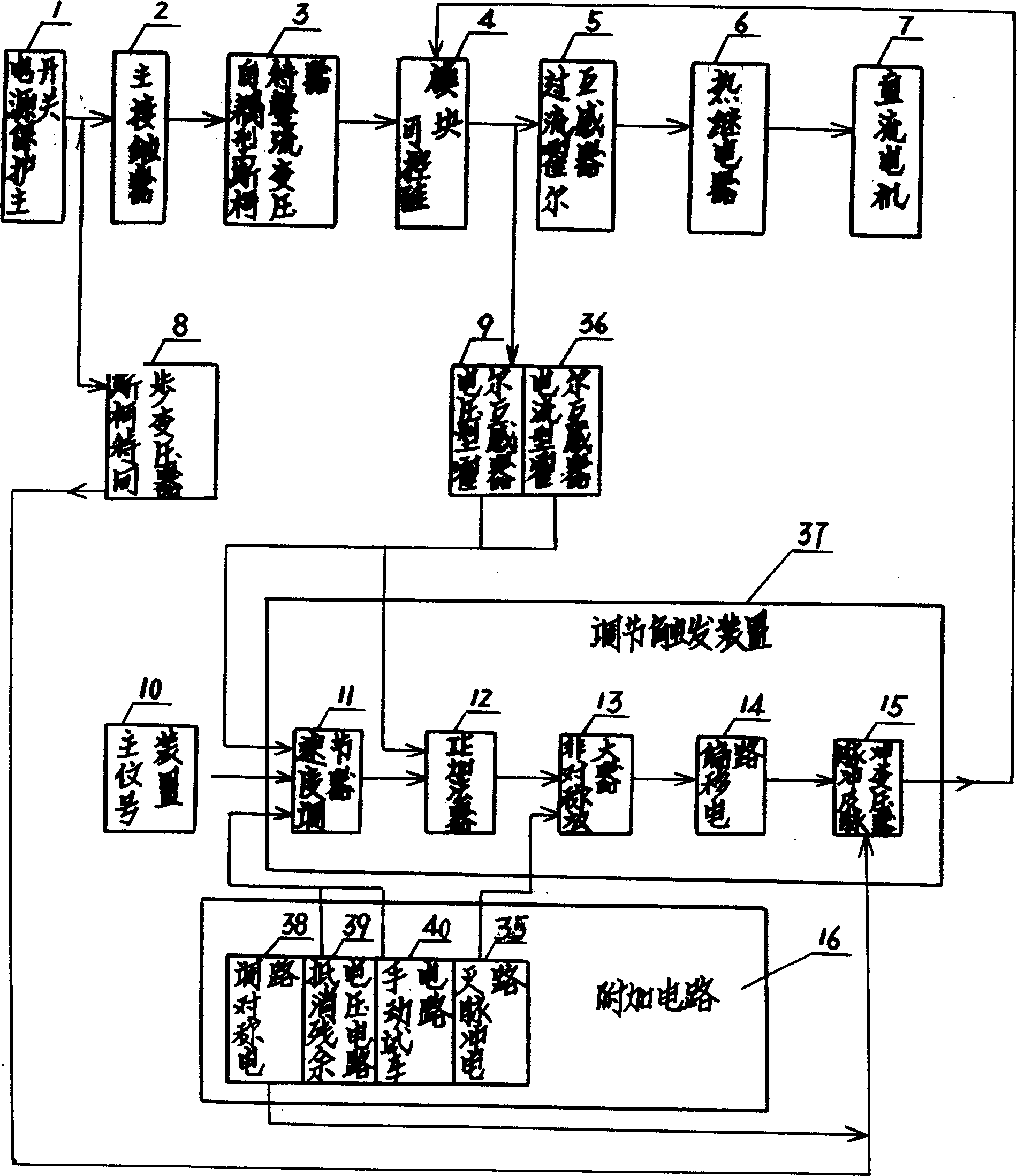

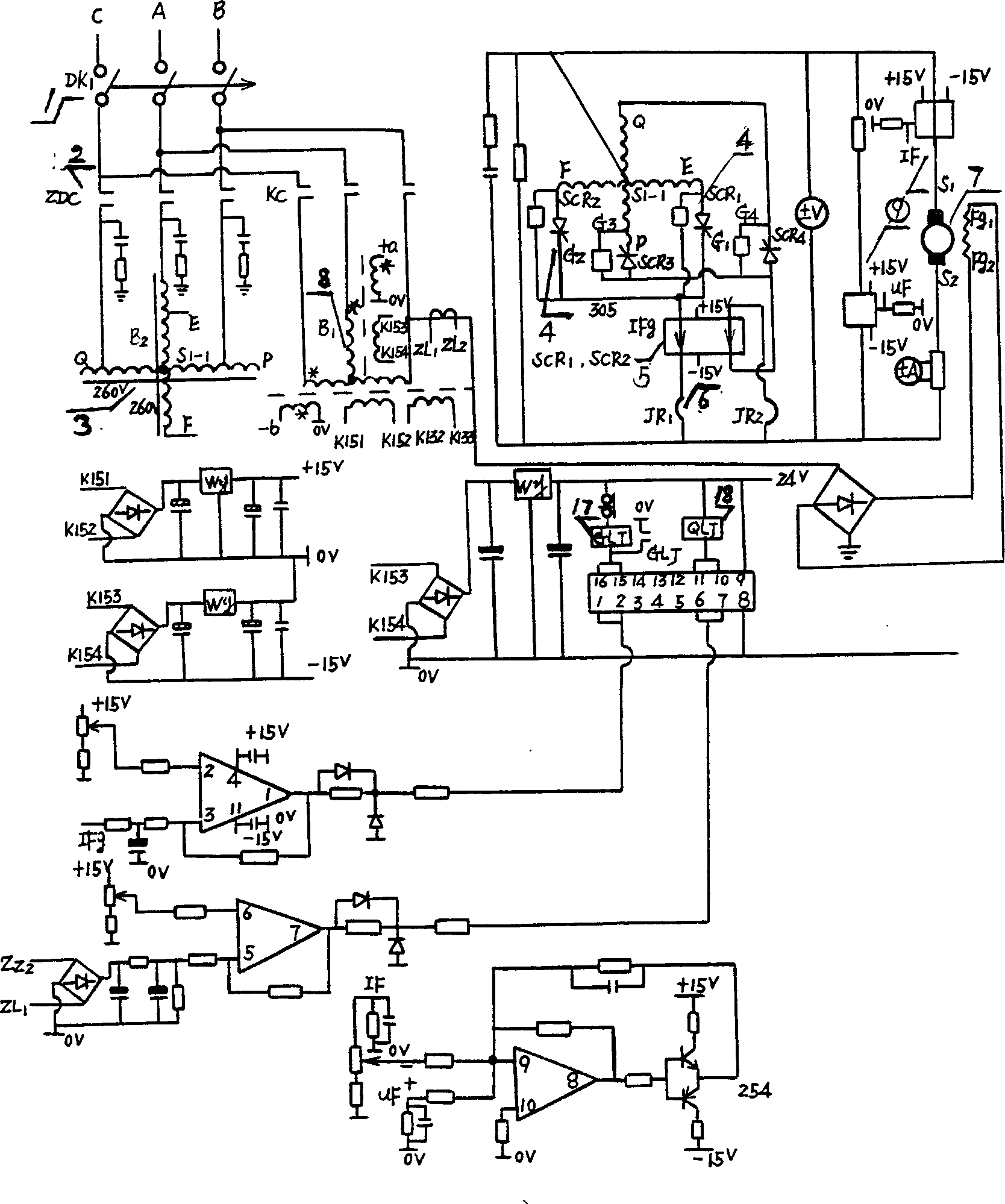

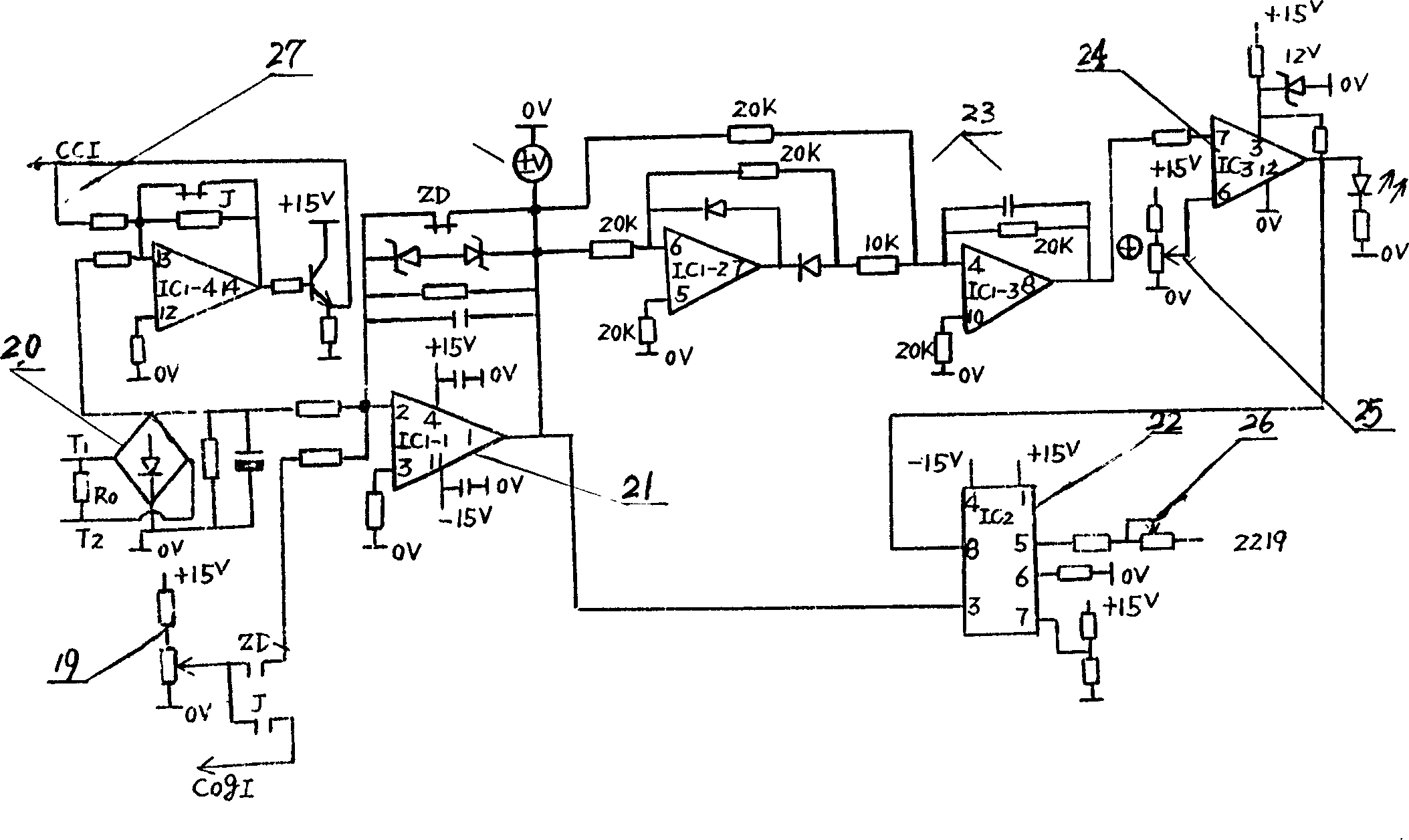

Electroslag furnace control system

InactiveCN1293355CSimple structureHigh control precisionControl devices for furnacesControl systemCirculating current

A control system of electroslag furnace is composed of power supply unit, primary signal unit, regulating trigger unit and auxiliary circuits. The main contactor and Scott synchronous transformer are connected to lower terminals of protecting switch for power supply unit. An auto-coupled Scott rectifying transformer has the input connected to main contactor and two outputs connected two SCR modules. The terminal 2219 of regulating trigger unit is serially connected to speed regulator, IE adder, static circulating current eliminator, shift circuit, pulse chip and pulse transformer.

Owner:沈阳工业学院

System and method for cleaning lens

InactiveCN102728586BEliminate static frictionWon't stayFlexible article cleaningEngineeringLens plate

The invention belongs to the field of lens cleaning and discloses a component, a system and a method for cleaning lens. The component for cleaning lens provided by the invention comprises an ion module, a first clamping module, a spraying module and a second clamping module. The spraying module performs spray wash on the surface of the lens by atomized alcohol, and a cleaning material is clamped by the first clamping module and the second clamping module to remove the impurity on the surface of the lens after spray wash. The surface of the lens is dried by the ion module and the frictional static on the surface of the lens is eliminated. The cleaning efficiency is high and the lens can be cleaned more cleanly without scratch on the surface of the lens. In addition, the cleaning method is simple and the operation is easy.

Owner:HUAZHONG UNIV OF SCI & TECH

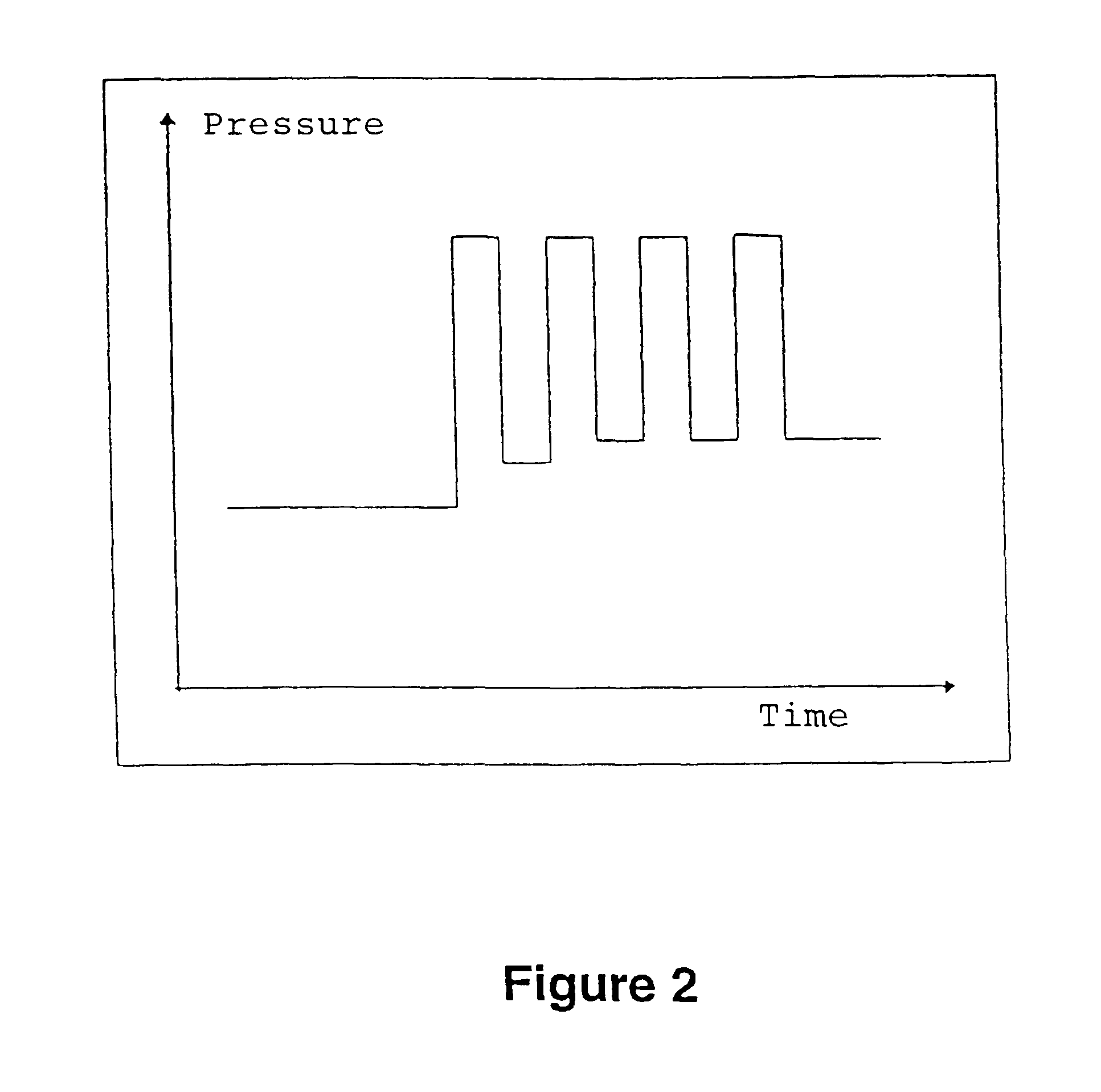

Pressure converter

InactiveCN107701526AEliminate static frictionConstant output pressureLiquid surface applicatorsFluid-pressure convertersLinear motionLiquid medium

Owner:MARCO SYSTEMANALYSE UND ENTWICKLUNG GMBH

Manufacturing method and device of U-shaped spring for elevator safety gear

ActiveCN104493445BReduce oxidationReduce generationFurnace typesHeat treatment furnacesSurface finishTempering

The invention discloses a manufacturing method of a U-shaped spring for elevator security pincers. The manufacturing method is that a spring steel bar is heated through a heating die applied to an induction furnace, and the U-shaped spring is formed under oil pressure effect through a forming oil pressure device for the U-shaped spring. The manufacturing method comprises the steps of (1) blanking, namely, processing bar steel into a spring steel bar with the specified length through a blanking machine; (2) heating the spring steel bar, namely heating the spring steel bar through the heating die applied to the induction furnace; (3) forming the U-shaped spring, namely, forming under the oil pressure through the forming oil pressure device for the U-shaped spring; (4) vibrating and chamfering, namely, vibrating the pressed and formed U-shaped spring through a grinding vibration machine together with grinding materials; (5) milling; (6) thermally processing the U-shaped spring, quenching and tempering; (7) performing surface finish. The U-shaped spring manufactured by the method has the advantages that decarburized layers of the spring are minimized, the oxidizing rate is low, the consistency of the mechanical properties is high, the service life is long, the spring is difficulty clamped on the forming die during discharging, and the manufacturing is energy saving and environmentally friendly.

Owner:上海核工碟形弹簧制造有限公司

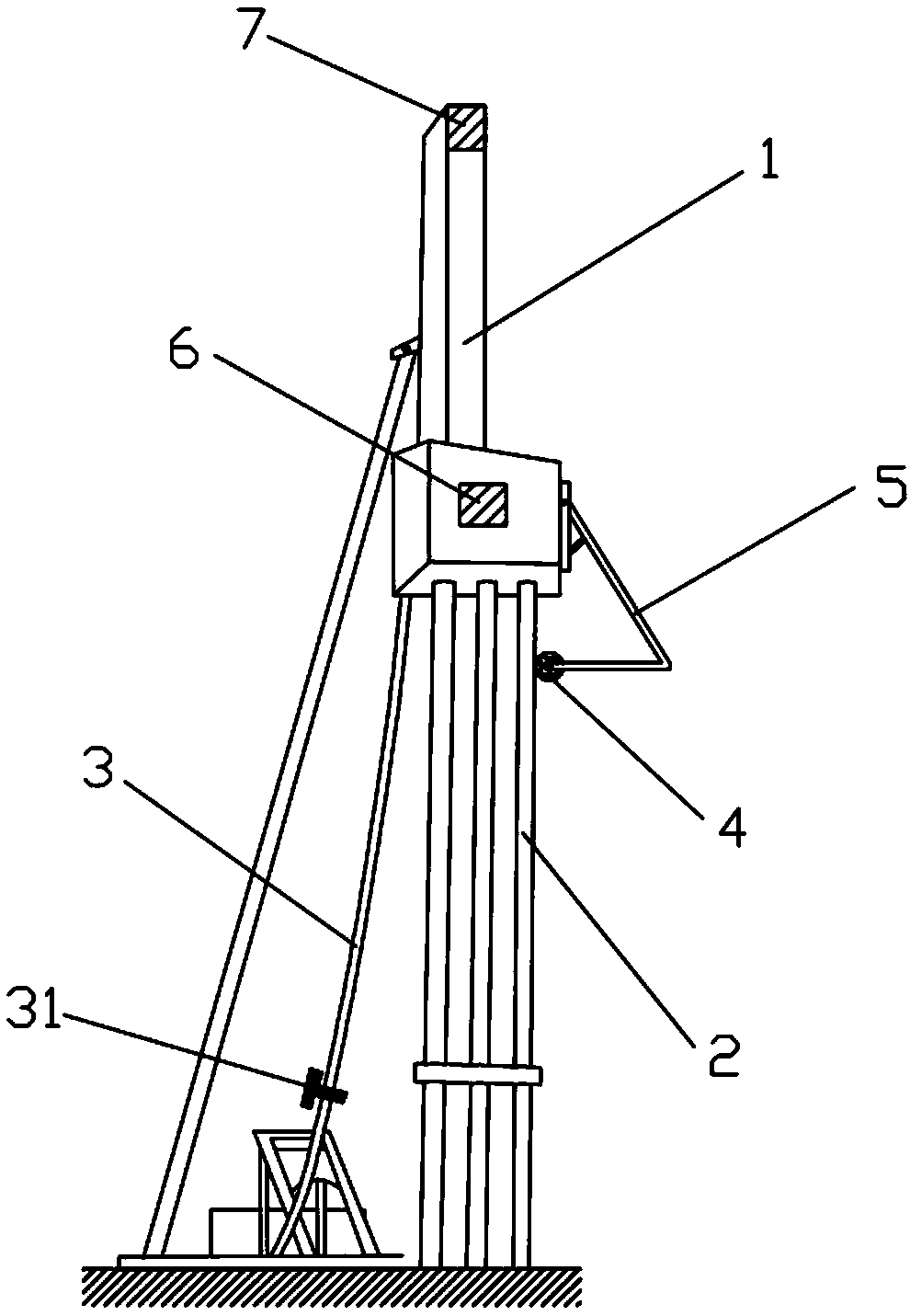

Cement Mixing Pile Quality Monitoring System

The invention relates to a cement mixing pile body quality monitoring system. The cement mixing pile body quality monitoring system comprises a rotation pouring type cement pile construction machine. The rotation pouring type cement pile construction machine comprises a rack. The rack is vertically provided with multiple rotary grouting pipes. The top ends of the rotary grouting pipes are connected with the tail end of a cement paste conveying pipe. The cement paste conveying pipe is provided with a cement paste flow meter. A meter counting wheel is closely attached to the peripheral side of the rotary grouting pipes and connected with a fixing frame arranged on the rack. A quality monitoring processor is further included and electrically connected with the meter counting wheel and the cement paste flow meter. The quality monitoring processor judges whether a cement mixing pile body is qualified or not according to the rotary grouting pipe feeding length collected by the meter counting wheel and the cement usage amount collected through the cement paste flow meter. The cement mixing pile body quality monitoring system automatically judges whether the cement mixing pile body is qualified or not according to the collected information so that remedial measures can be taken before curing of the cement mixing pile body, and benefits of customers are guaranteed.

Owner:FUZHOU INSTITUE OF TECH

A flexible yarn clearing device for yarn winding processing

The invention discloses a flexible yarn clearing device for yarn winding processing, and relates to the technical field of yarn winding production and manufacturing; in order to solve the problem of poor cleaning quality; it specifically includes a machine body, and the inner walls of the opposite sides of the machine body are equipped with There is a first electric chute, and the inner walls of the two first electric chutes are provided with the same upper mold base; the top outer wall of the body is provided with a lower mold base, and the top outer wall of the lower mold base and the bottom outer wall of the upper mold base are both There are more than four lead grooves, and the inner walls of more than four lead grooves are all wave-shaped structures. The lower mold base and the upper mold base are matched. The inner walls of the opposite sides of the four or more lead grooves are all bonded with a protective layer. The sponge of the present invention is soaked by the water in the water tank, and the rotating roller on the lower mold base is soaked by the sponge when it rotates, so the yarn is soaked when it contacts the rotating roller during transmission, thereby eliminating its frictional static electricity and avoiding the absorption of impurities in the later stage. Guaranteed cleaning quality.

Owner:衡阳新新纺织机械有限公司

Electroslag furnace control system

InactiveCN1427238ASimple structureHigh control precisionControl devices for furnacesControl systemCirculating current

A control system of electroslag furnace is composed of power supply unit, primary signal unit, regulating trigger unit and auxiliary circuits. The main contactor and Scott synchronous transformer are connected to lower terminals of protecting switch for power supply unit. An auto-coupled Scott rectifying transformer has the input connected to main contactor and two outputs connected two SCR modules. The terminal 2219 of regulating trigger unit is serially connected to speed regulator, IE adder, static circulating current eliminator, shift circuit, pulse chip and pulse transformer.

Owner:沈阳工业学院

Manufacturing method and device for U-shaped spring for elevator safety clamp

InactiveCN108747217AIncrease consumptionReduce utilizationWire springsEnvironmental resistanceSteel bar

The invention discloses a manufacturing method and device for a U-shaped spring for an elevator safety clamp. Spring steel strip heating is conducted through a heating die of an induction furnace, andU-shaped spring forming is conducted through oil pressure forming via a U-shaped spring forming oil pressure device. The following technology steps are included, firstly, discharging is conducted, and a discharging machine is used for machining a steel bar into a spring steel strip with the assigned length; secondly, spring steel strip heating is conducted, and the spring steel strip is placed onthe heating die of the induction furnace to be heated; thirdly, U-shaped spring forming is conducted, and the U-shaped spring forming oil pressure device is adopted for oil pressure forming; fourthly, vibration chamfering is conducted, the pressed formed U-shaped spring is placed in a grinding vibrator to vibrate together with abrasive materials; fifthly, milling machining is conducted; sixthly,the U-shaped spring is subjected to heat treatment, quenching treatment and tempering treatment; and seventhly, surface treatment is conducted. According to the U-shaped spring manufactured through the manufacturing method and device, few spring decarburized layers exist, the oxidized rate is low, mechanical character consistency is high, the service life is long, the spring is not prone to beingclamped to a forming die during material stripping, and energy saving and environment friendliness are achieved in the manufacturing process.

Owner:JIANGSU XIANGYING HARDWARE SPRING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com