Forming mold for U-shaped spring

A forming mold and U-shaped technology, applied in the field of U-shaped spring forming molds, can solve problems such as safety accidents, non-perpendicular sides and bottoms, affecting product force value performance, etc., and achieve the effect of avoiding safety accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order for those skilled in the art to further understand the features and technical content of the present invention, please refer to the following detailed description and accompanying drawings of the present invention.

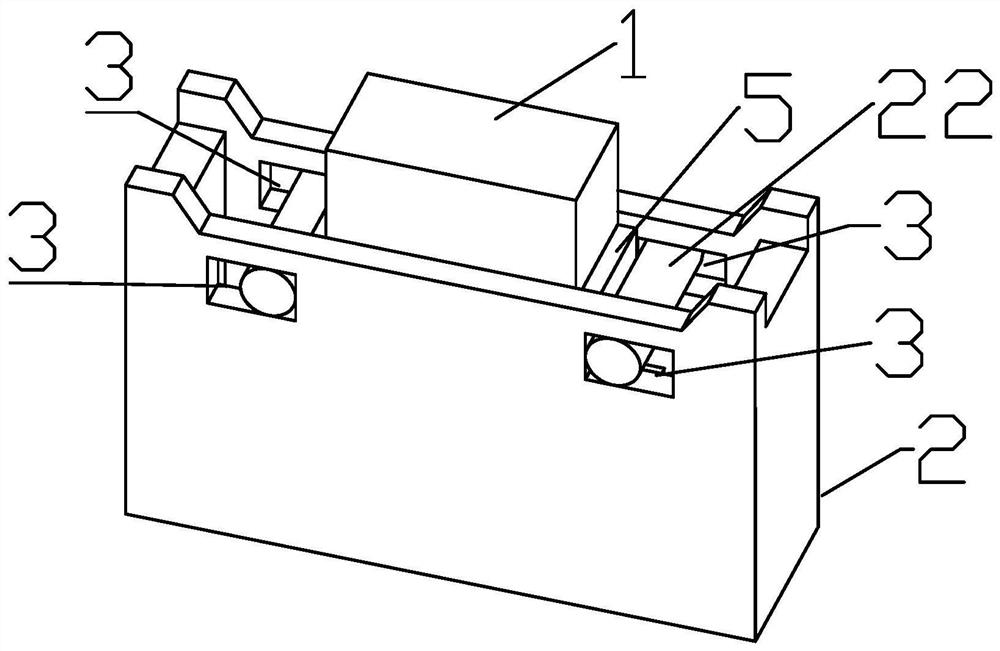

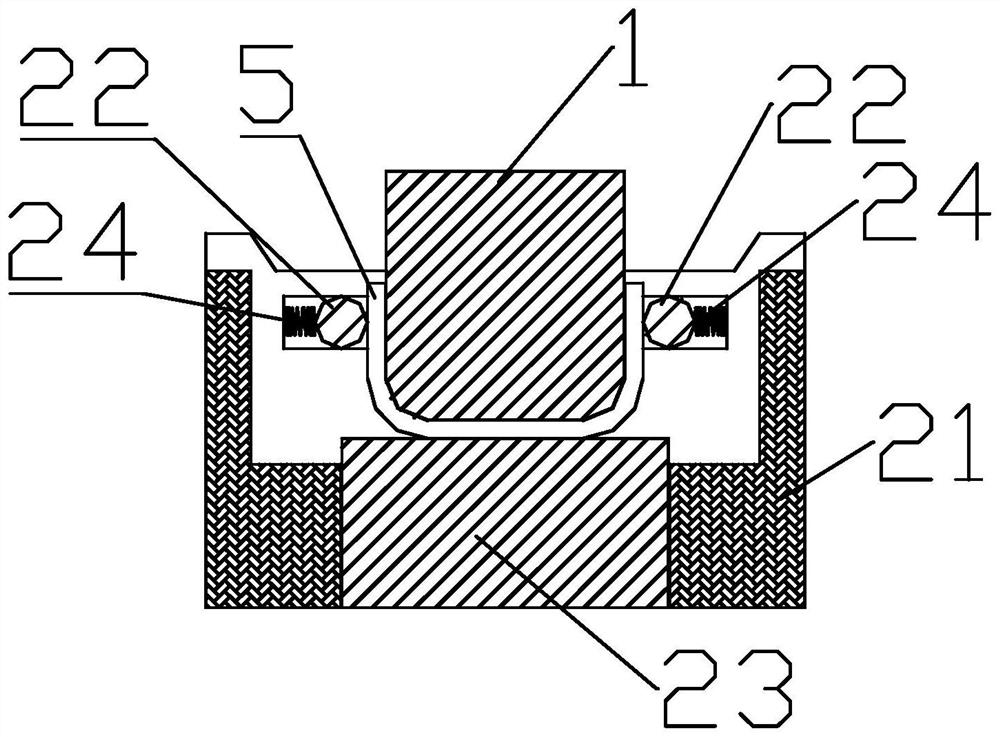

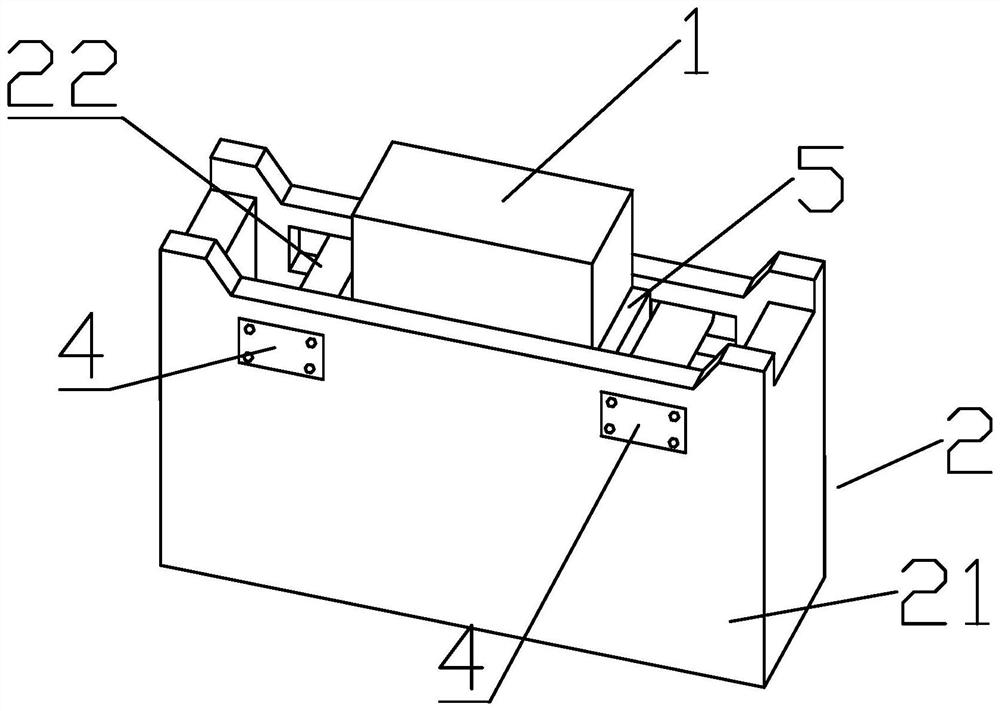

[0020] Such as Figure 1-3 Shown, a kind of forming mold of U-shaped spring comprises upper mold 1 and lower mold 2, and lower mold comprises lower mold body 21, forming roller 22, lower mold protrusion 23, helical spring 24, and the inside of lower mold body 21 A molding cavity with an upper opening is formed, the upper mold 1 is arranged in the molding cavity, and the left and right sides of the lower mold body 21 near the top edge are respectively provided with two square holes 3, and the square holes 3 on the left and right sides are respectively The forming roller 22 is installed, and the forming roller 22 radially fits with the width of the square hole 3. The central axis of the forming roller 22 is perpendicular to the central axis of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com