Manufacturing method and device of U-shaped spring for elevator safety gear

A manufacturing method and technology of safety gear, applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., can solve the problems of inconsistency in forming pressure holding time, poor consistency of mechanical properties, and low utilization rate of equipment, so as to reduce human operation errors, Effect of shortening heating time and low utilization rate of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order for those skilled in the art to further understand the features and technical content of the present invention, please refer to the following detailed description and accompanying drawings of the present invention.

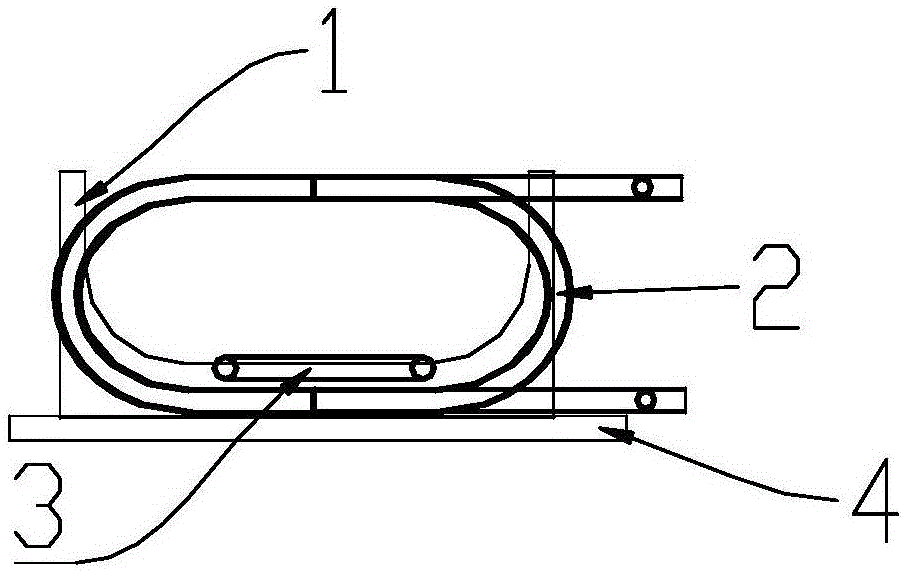

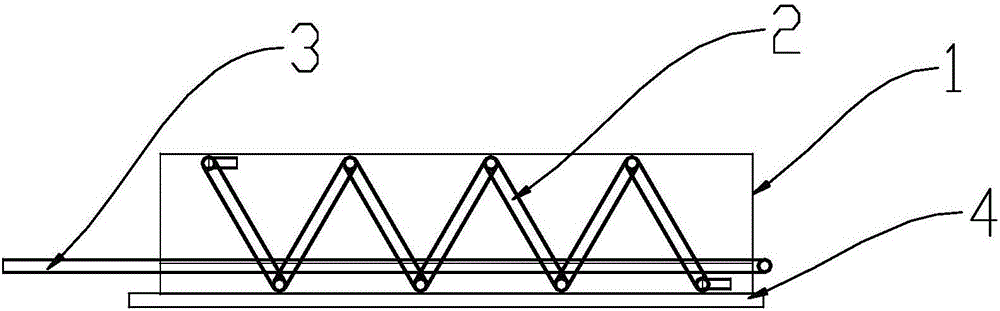

[0051] The manufacturing method of the U-shaped spring for elevator safety gear, the spring material is bar steel, the spring steel bar is heated by a heating mold used in an induction furnace, and the U-shaped spring is formed by a U-shaped spring forming oil pressure device, including the following Process steps:

[0052] (1) Cutting

[0053] Process the bar steel into a spring steel bar of specified length through the blanking machine;

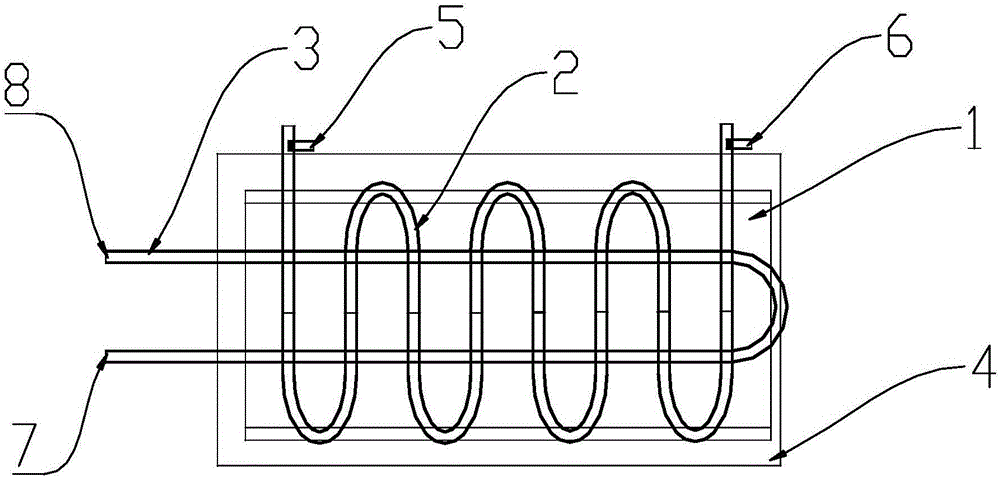

[0054] (2) Spring steel bar heating

[0055] Set the heating time and temperature of the induction furnace, put the spring steel bar on the heating mold for the induction furnace to heat; the induction furnace heating time is set to 15 seconds, the heating temperature is set to 750 degrees, and the heating mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com