Electroslag furnace control system

A control system and electroslag furnace technology, applied in the direction of furnace control devices, furnaces, furnace components, etc., can solve the problems of low control precision, slow response speed, dead zone, etc., and achieve high control precision, fast response speed, The effect of eliminating static friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

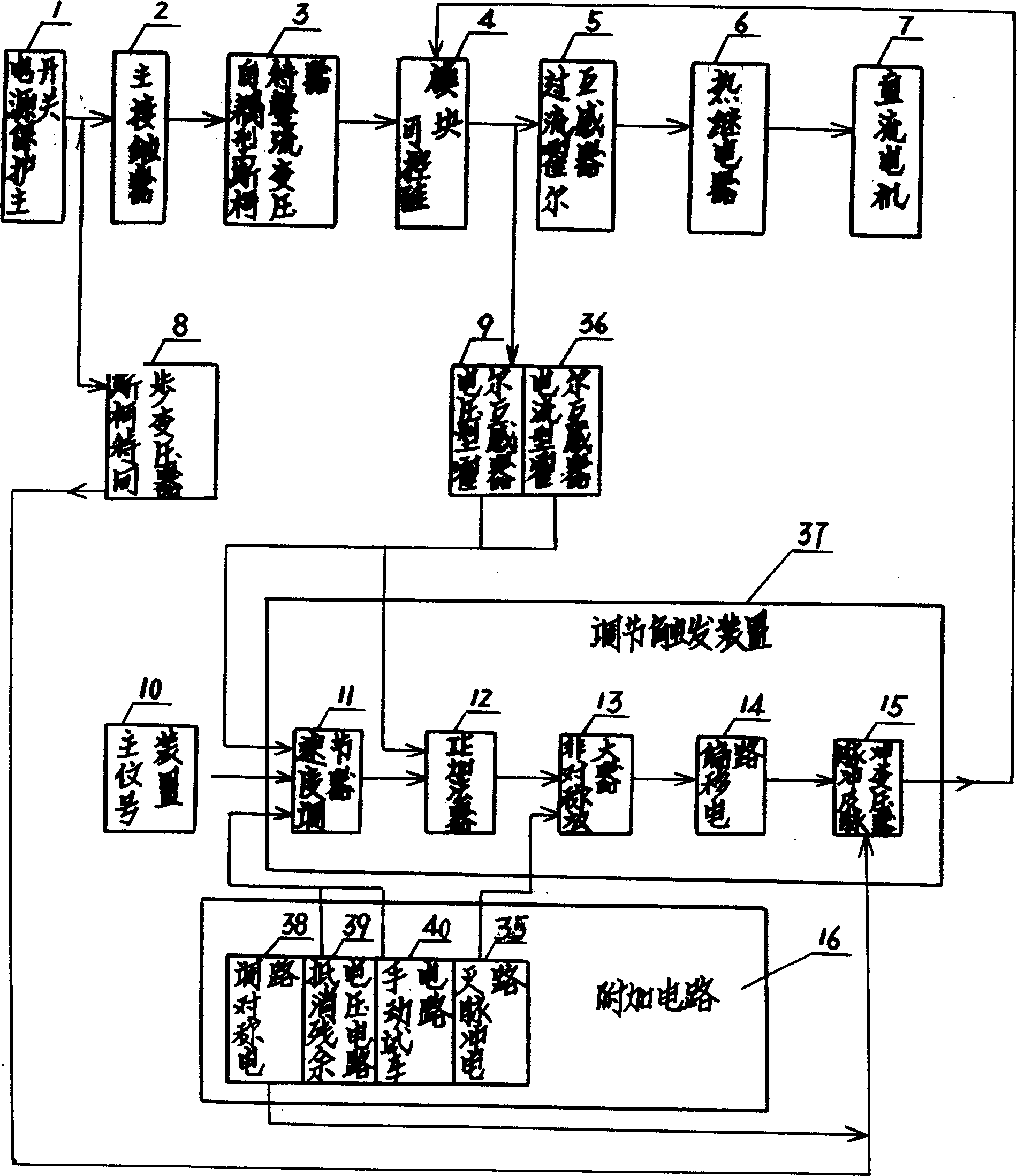

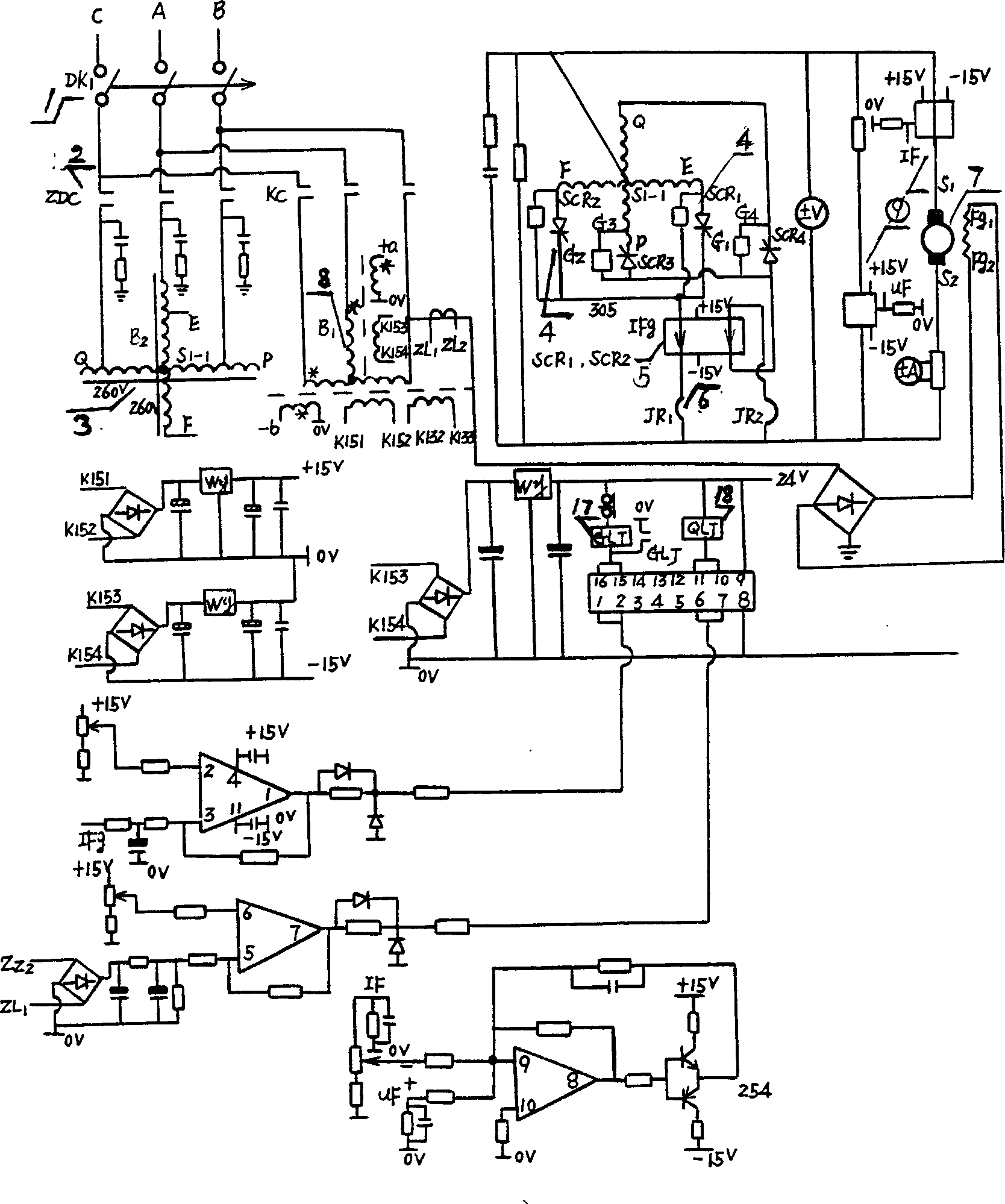

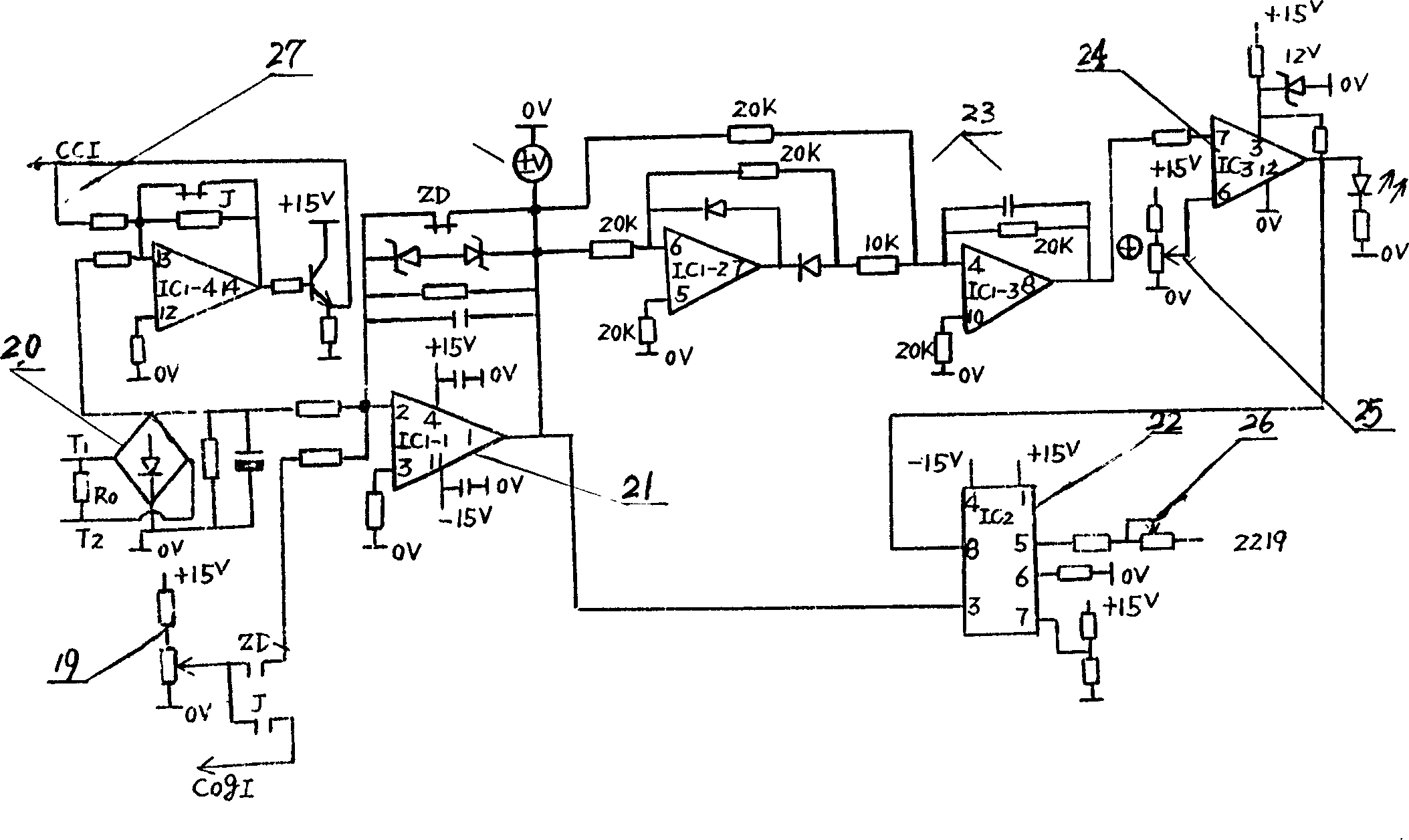

[0017] Such as figure 1 As shown, the present invention consists of a power supply protection main air switch 1, a main contactor 2, an auto-coupling Scott rectifier transformer 3, two thyristor modules 4, an overcurrent Hall transformer 5, a thermal relay 6, and a DC motor 7. Scott synchronous transformer 8, voltage type Hall transformer 9, main signal device 10, speed regulator 11, IE adder 12, asymmetric amplifier 13, offset circuit 14 and pulse and pulse transformer 15, and regulation Trigger device 37, adjust symmetry circuit 38, offset residual voltage circuit 39, the additional circuit 16 that manual test run circuit 40 forms. The power supply device of the present invention is as figure 2 As shown, the main contactor 2 and the Scott synchronous transformer 8 are connected to the lower end of the power protection main switch at the same time, and the output terminals +a and -b of the Scott synchronous transformer 8 are respectively connected to two A pulse chip is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com