Pressure converter

A converter and pressure technology, used in fluid pressure converters, fluid pressure actuators, semiconductor devices, etc., can solve problems such as output pressure fluctuations, and achieve the effects of eliminating static friction, low price, and low manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

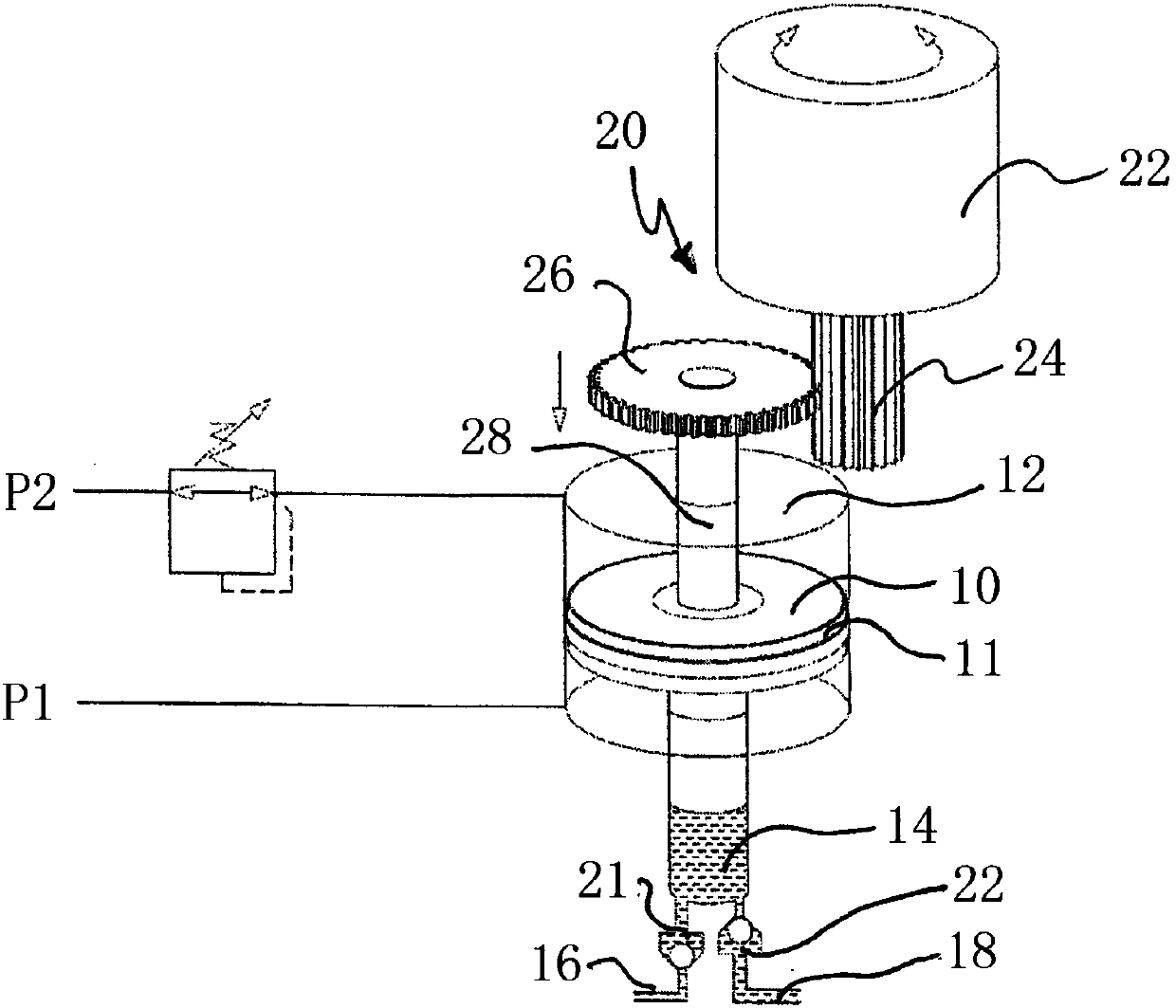

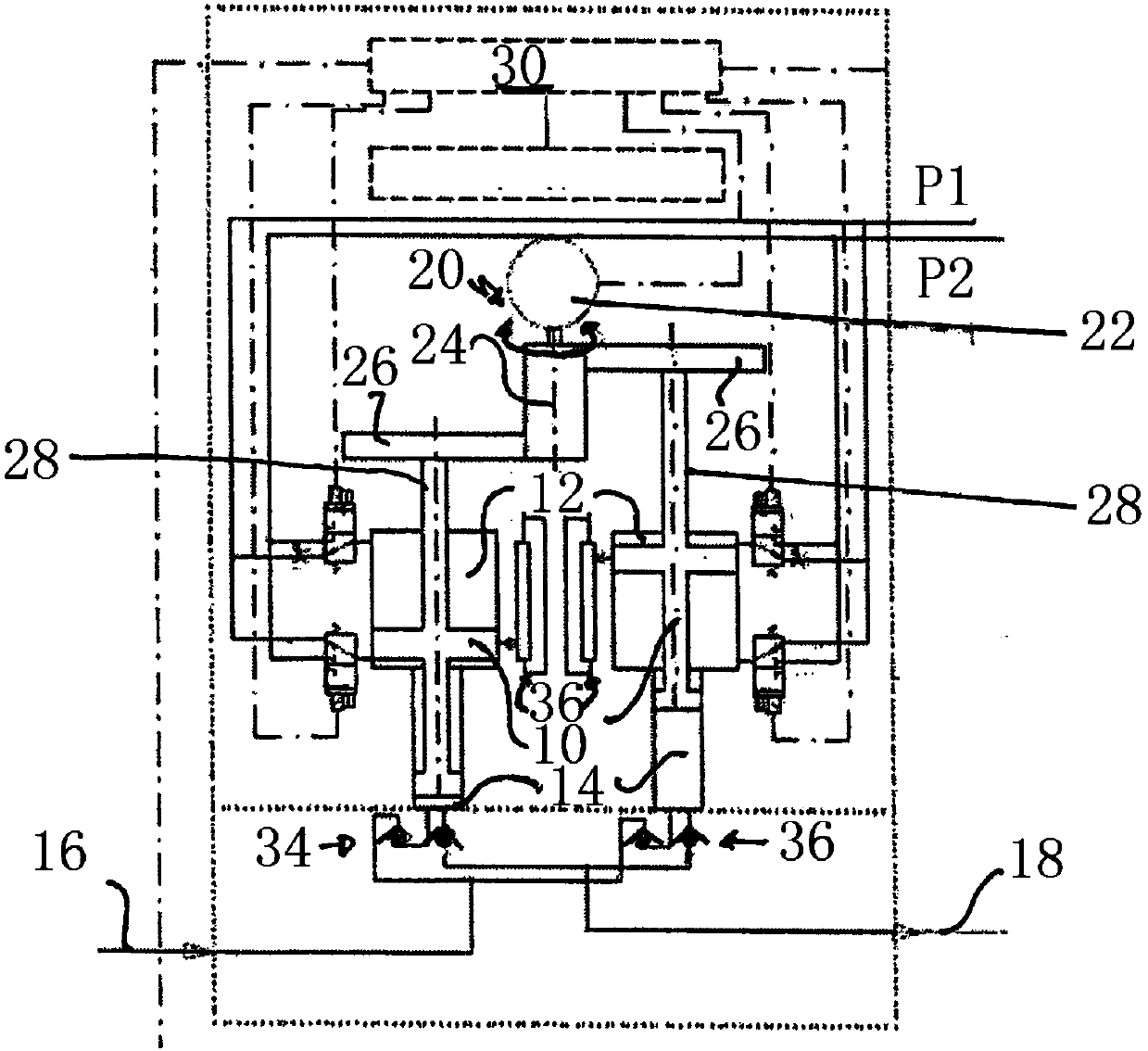

[0023] figure 1 A first embodiment of a pressure transducer for liquid media is shown, which comprises a piston 10 which can be moved back and forth in a linear movement along a longitudinal axis in a piston chamber 12 . The piston 10 has a first cross section in the piston chamber 12 which is larger than a second cross section of the piston 10 which extends in the medium chamber 14 . As a result, a pressure conversion in proportion to the piston surface is possible in a manner known per se.

[0024] The medium chamber 14 is provided with an inlet 16 and an outlet 18 , wherein in the inlet 16 and in the outlet 18 there are non-return valves 21 and 22 connected in opposite directions.

[0025] In order to simultaneously move the piston 10 back and forth in the piston chamber 12 and in the medium chamber 14 , a linear drive (not shown in detail) in the form of two pressure lines P1 and P2 is provided. The piston 10 can be moved back and forth along the longitudinal axis in a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com