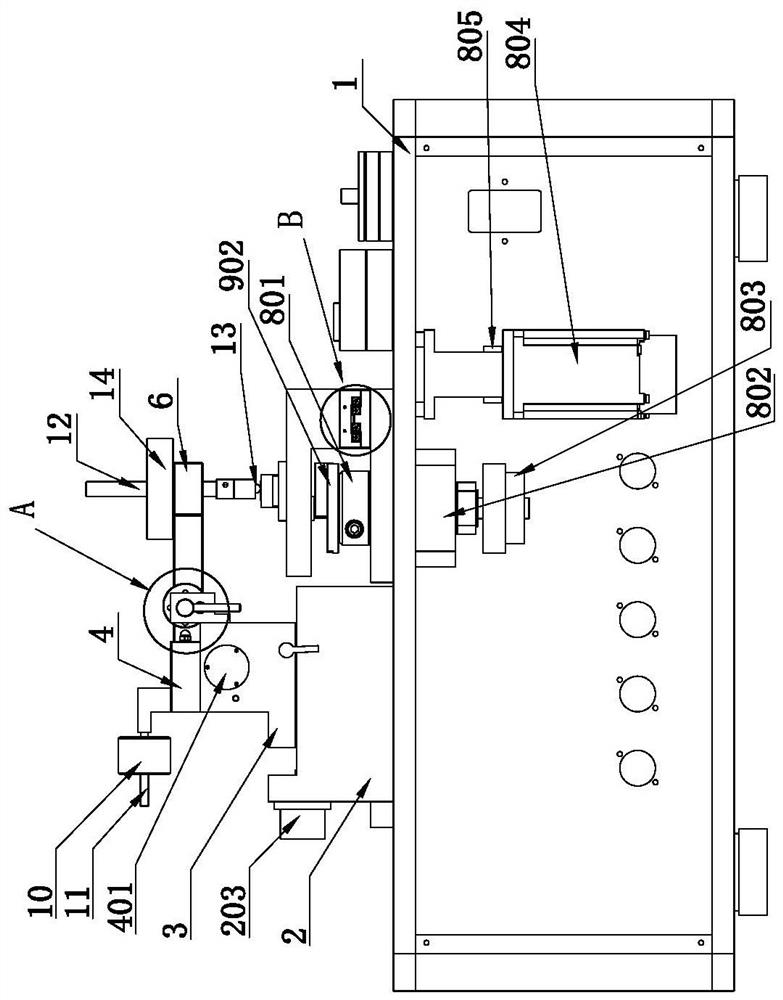

Multifunctional weight loading friction wear testing machine

A friction and wear test, multi-functional technology, applied in the field of mechanical testing, can solve the problems of low detection accuracy and single function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

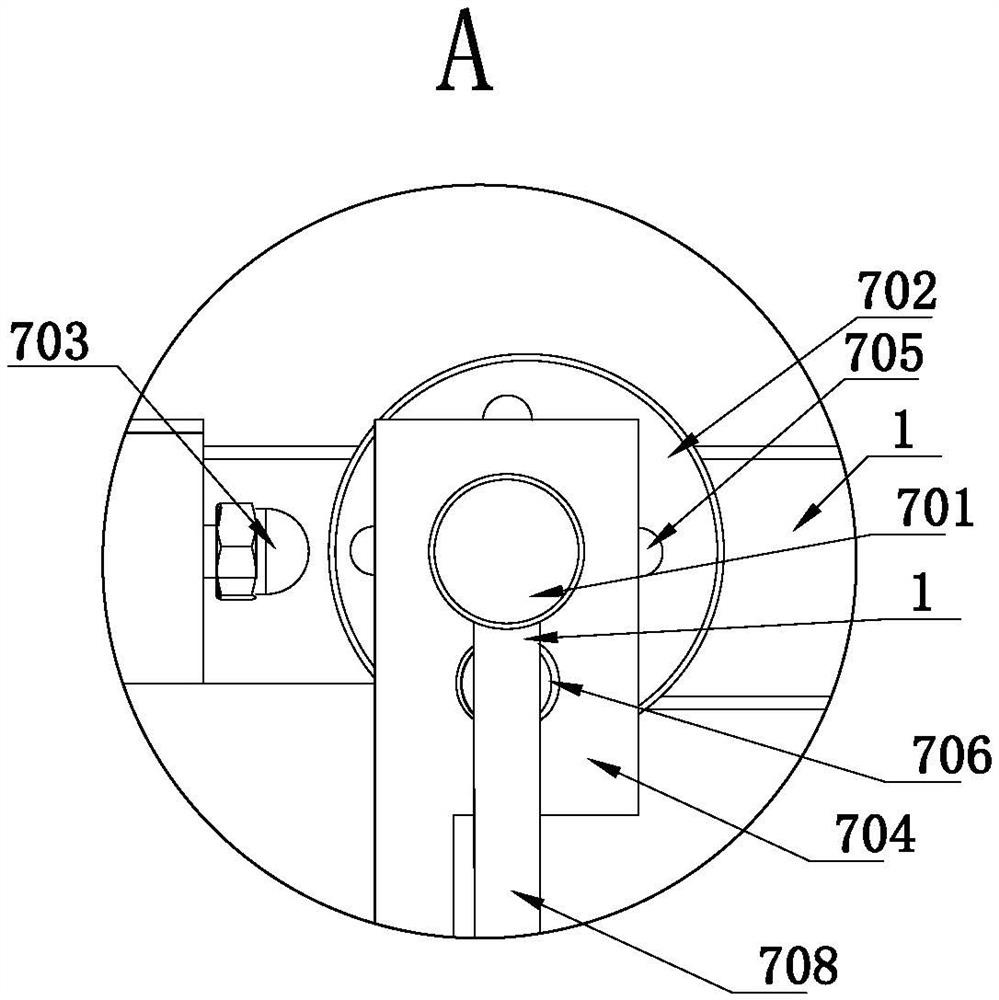

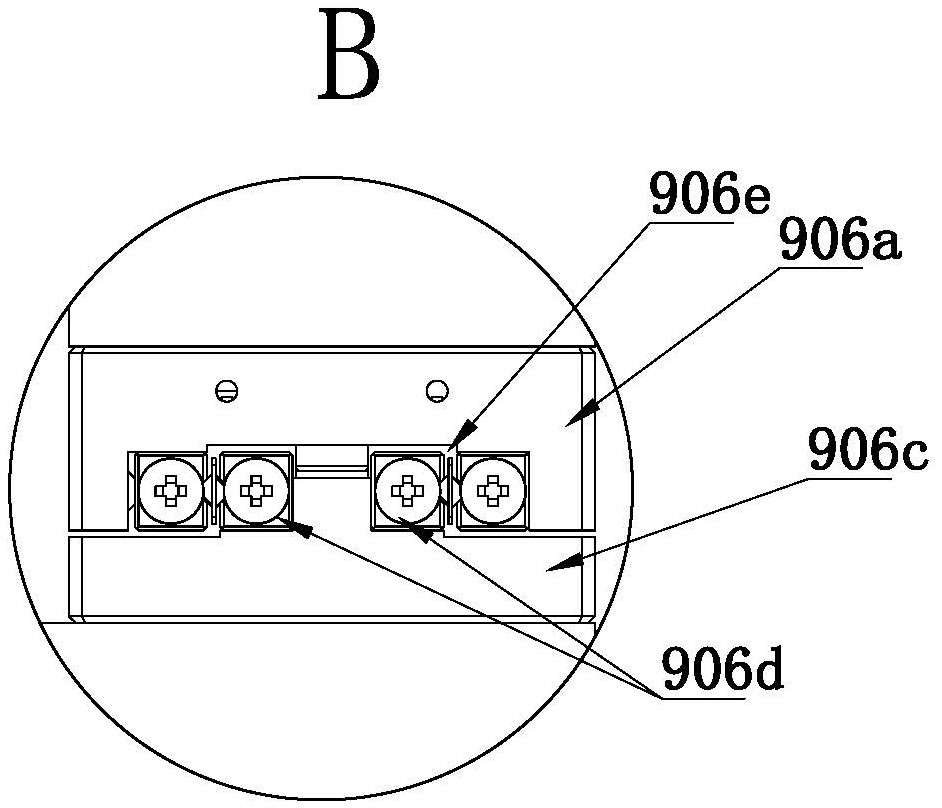

[0037] Such as Figure 14 The multifunctional weight 14 shown is loaded on the friction and wear testing machine. The difference between this implementation and Embodiment 1 is that a fixing hole 801b is provided on the rotating shaft 801, and the clamping mechanism 9 includes a three-jaw chuck 907, and the three-jaw chuck The connecting shaft 2 908 of 907 can be plugged in the fixing hole 801b, the side of the rotating shaft 801 has a limiting hole 801a, and the limiting hole 801a is provided with a limiting rod 801c, and the limiting rod 801c can lock the connecting shaft 2 908 on the rotating shaft On 801, the driving motor 804 drives the driving wheel 805, the driving wheel 805 drives the driven wheel 803 through the belt transmission, the rotation of the driven wheel 803 drives the rotating shaft 801, the rotation of the rotating shaft 801 drives the three-jaw chuck 907, and the three-turn chuck drives the sample to rotate, The sample is subjected to the action of the bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com