Flexible yarn clearing device for yarn spooling processing

A flexible, winding technology, applied in the direction of transportation and packaging, conveying filamentous materials, thin material processing, etc., can solve the problems of static electricity in the yarn and poor cleaning quality, so as to protect the yarn and ensure cleaning. quality, the effect of eliminating frictional static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

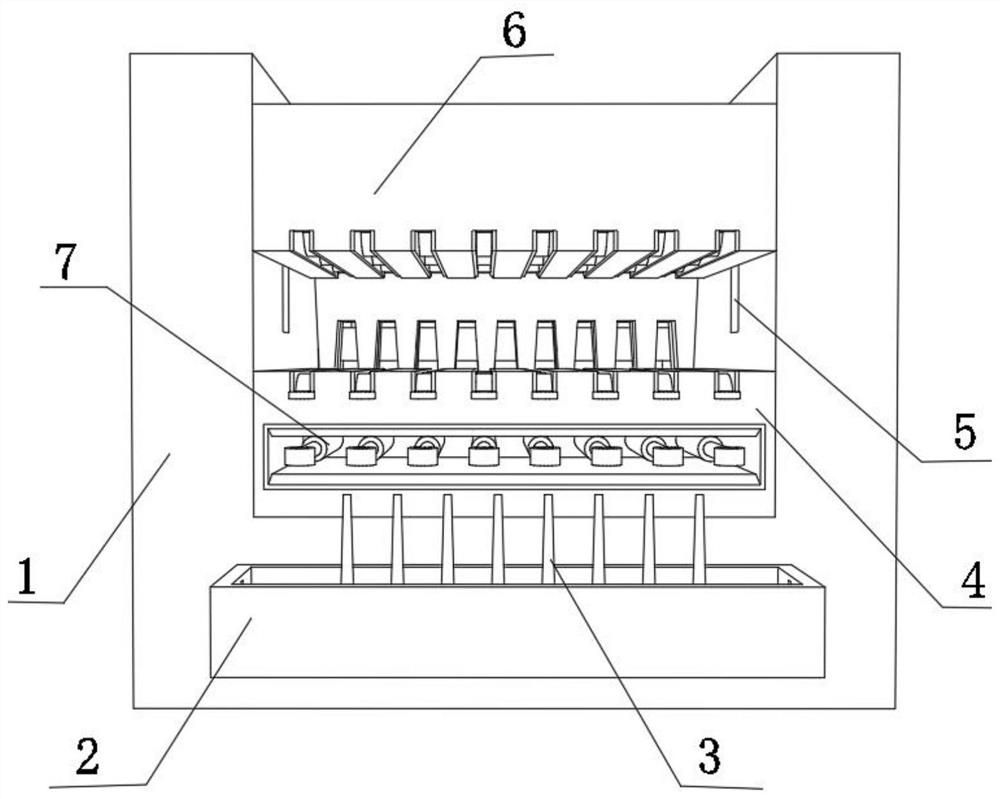

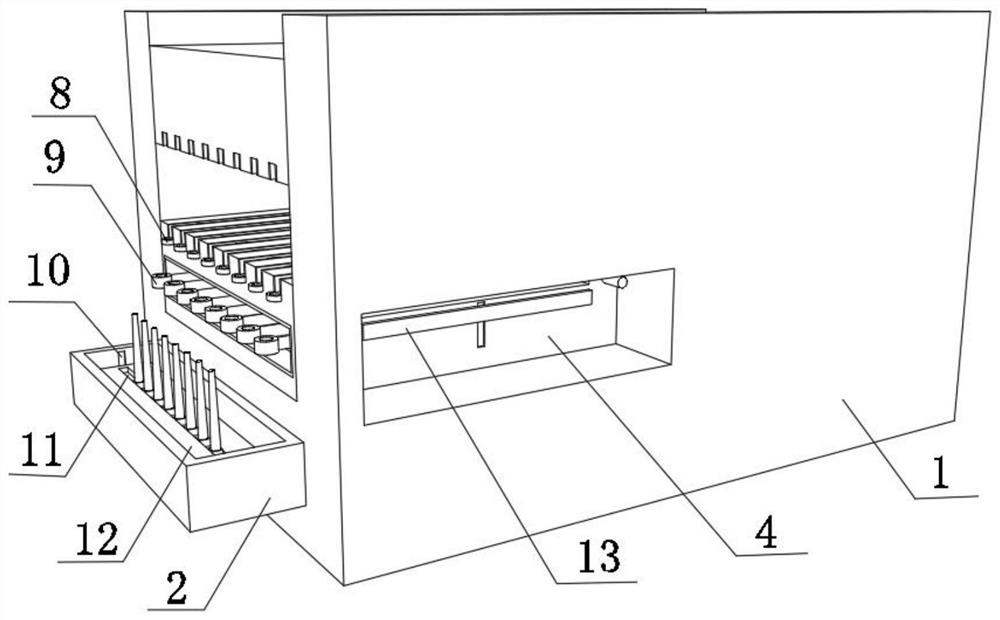

[0035] A flexible yarn clearing device for yarn winding processing, such as figure 1 and Figure 5-7 As shown, including the body 1, the inner wall of the opposite side of the body 1 is provided with a first electric chute 5, and the inner walls of the two first electric chute 5 are slidably connected with the same upper mold base 6 through a slider; The top outer wall of the machine body 1 is fixed with a lower mold base 4 by bolts, and the top outer wall of the lower mold base 4 and the bottom outer wall of the upper mold base 6 are provided with more than four lead grooves, and the inner walls of more than four lead grooves are corrugated. Shaped structure, the lower mold base 4 and the upper mold base 6 fit together, and the inner walls on the opposite side of the four or more lead grooves located on the lower mold base 4 and the four or more lead grooves located on the upper mold base 6 are bonded with a protective layer 24. The four or more lead wire grooves located on ...

Embodiment 2

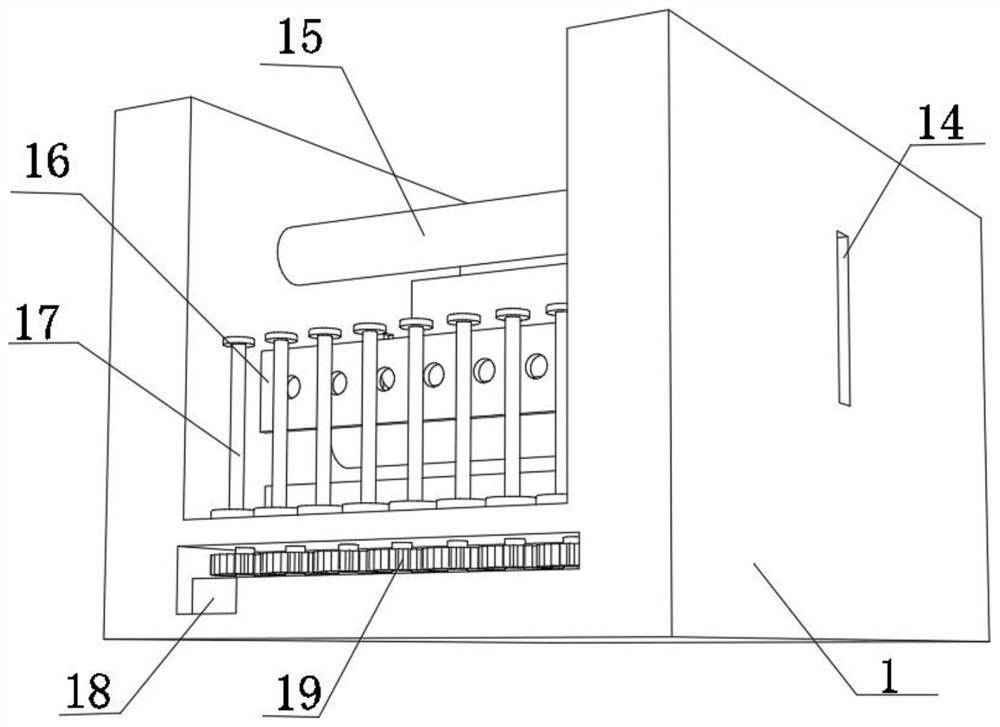

[0041] A flexible yarn clearing device for yarn winding processing, such as Figure 4 As shown, in order to dry the yarn; this embodiment makes the following improvements on the basis of embodiment 1: the inner wall of the opposite side of the body 1 is provided with electric slide rails 21, and the inner walls of the two electric slide rails 21 The same pinch roller 22 is slidably connected through the slider, and the inner wall of the body 1 close to the pinch roller 22 is connected with the supporting roller through the rotating shaft, and the inner wall of the side of the body 1 is connected with two drying rollers of different heights through the rotating shaft. Roller 15, the inner walls of the two drying rollers 15 are filled with a heating layer, the cleaned yarn passes between the supporting roller and the pinch roller 22, adjusts the downward distance of the pinching roller 22, passes through the supporting roller and the pinching roller The extruding at 22 dehumidif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com