Constant tension cable storage system for optical fiber cable processing

A fiber optic cable, constant tension technology, applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the mismatch of cable pay-off and take-up speed, cable tearing, and cable loosening and other issues to achieve the effect of improving production and processing efficiency and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

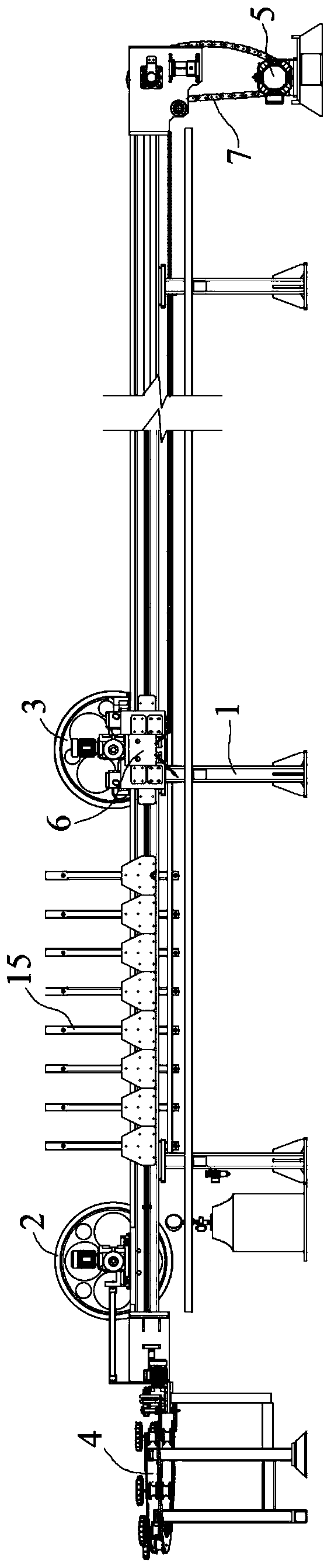

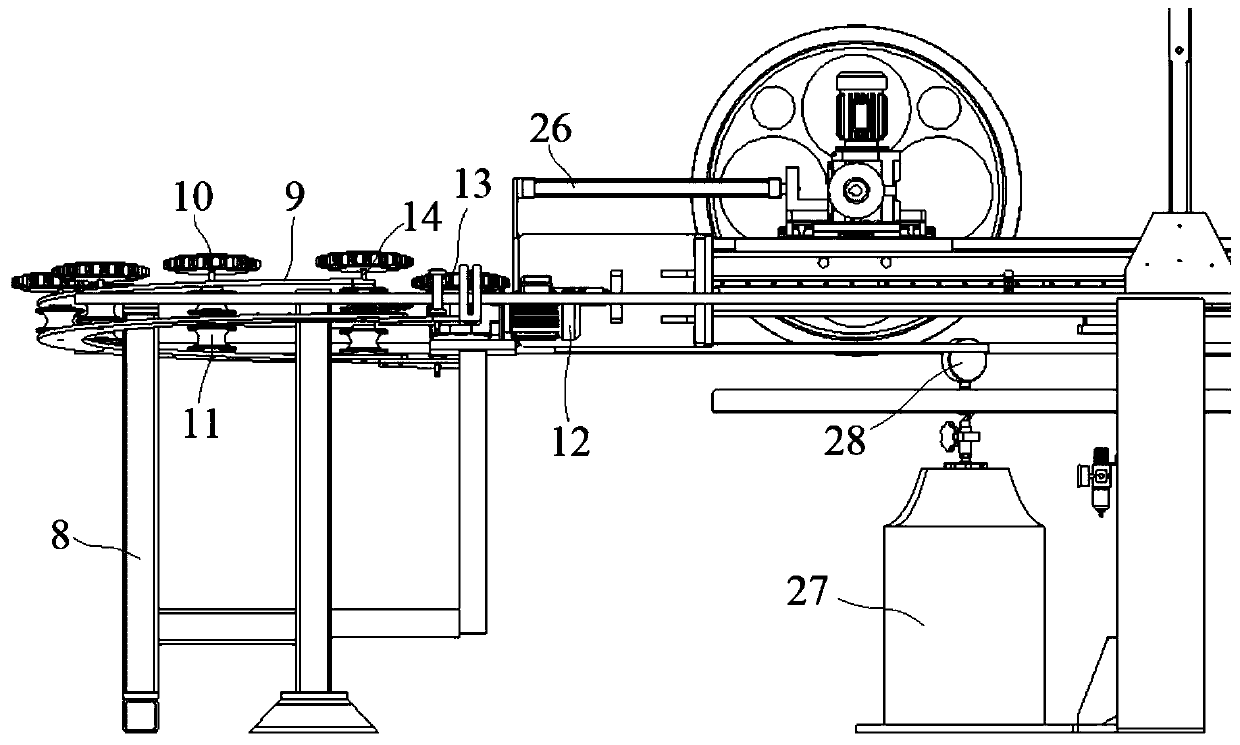

[0035] Embodiment 1: A constant tension wire storage system for optical fiber and cable processing, including a support 1, a first wire storage wheel set 2, a second wire storage wheel set 3, a guide mechanism 4 and a drive mechanism 5, the first storage The wire wheel group 2 and the second wire storage wheel group 3 are installed on the support 1, the guide mechanism 4 is located at one end of the support 1, and the driving mechanism 5 is arranged at the other end of the support 1;

[0036]The second wire storage wheel set 3 is movably mounted on the support 1 through a movable seat 6, and the driving mechanism 5 is connected with the movable seat 6 through a chain 7 for driving the second wire storage wheel set 3 in the Move on the support 1 along the length direction of the support 1 to approach or move away from the first line storage wheel set;

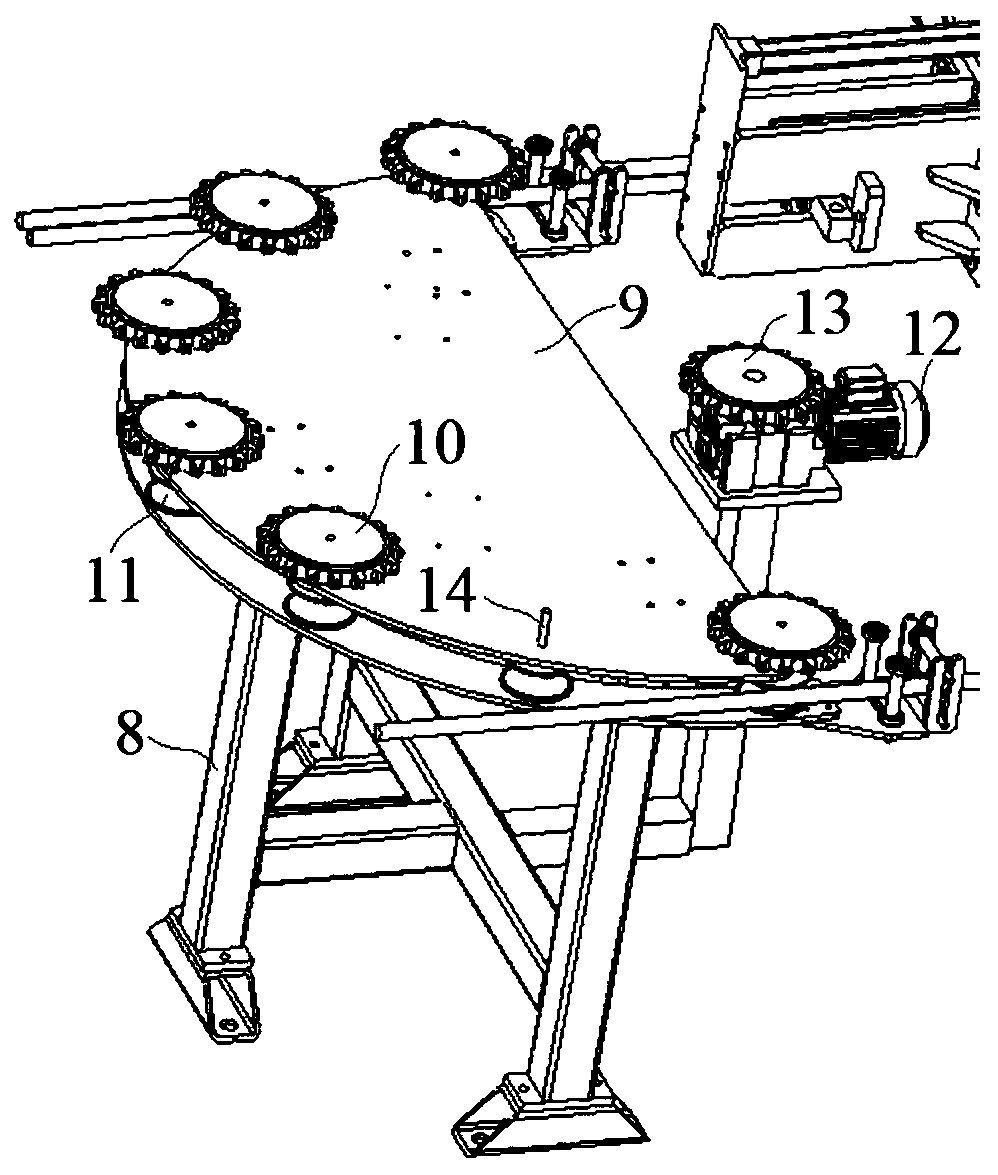

[0037] Described guiding mechanism 4 comprises base 8, the semicircle mounting plate 9 that is installed on the base 8 and som...

Embodiment 2

[0043] Embodiment 2: A constant tension wire storage system for optical fiber and cable processing, including a support 1, a first wire storage wheel set 2, a second wire storage wheel set 3, a guide mechanism 4 and a drive mechanism 5, the first storage The wire wheel group 2 and the second wire storage wheel group 3 are installed on the support 1, the guide mechanism 4 is located at one end of the support 1, and the driving mechanism 5 is arranged at the other end of the support 1;

[0044] The second wire storage wheel set 3 is movably mounted on the support 1 through a movable seat 6, and the driving mechanism 5 is connected with the movable seat 6 through a chain 7 for driving the second wire storage wheel set 3 in the Move on the support 1 along the length direction of the support 1 to approach or move away from the first line storage wheel set;

[0045] Described guiding mechanism 4 comprises base 8, the semicircle mounting plate 9 that is installed on the base 8 and so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com