Method for improving mechanical property of ceramic polymer composite material

A composite material and polymer technology, which is applied in the preparation of ceramic polymer composite materials, can solve the problems of low resin content, easy crack development, and unusable materials, so as to improve rigidity and strength, improve mechanical properties, and high service temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

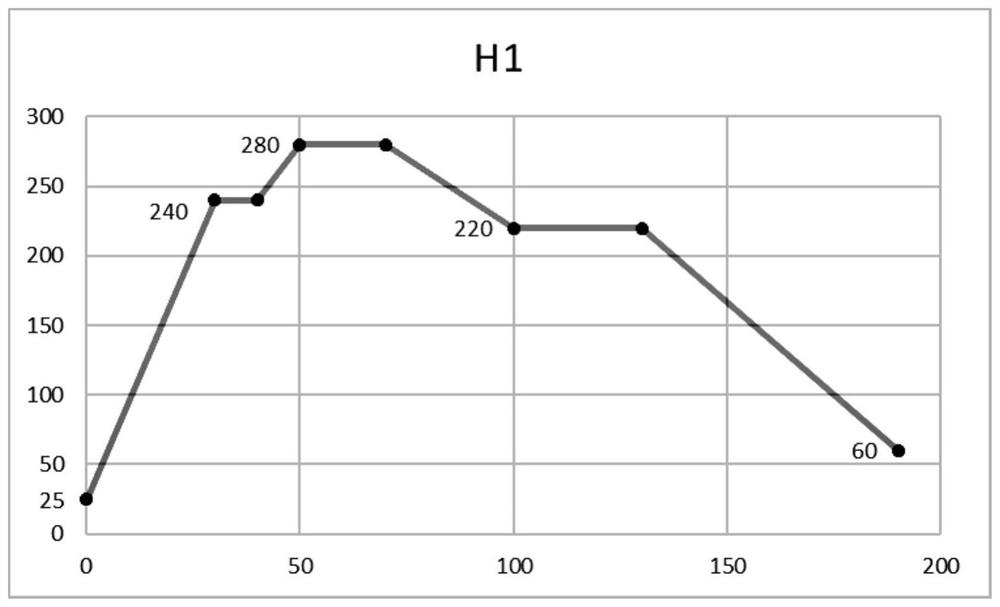

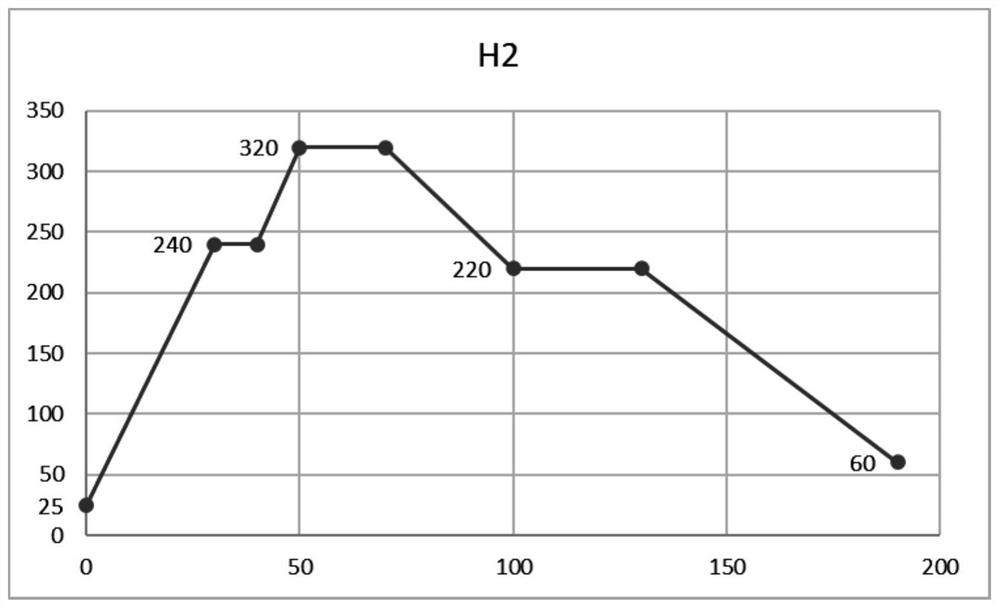

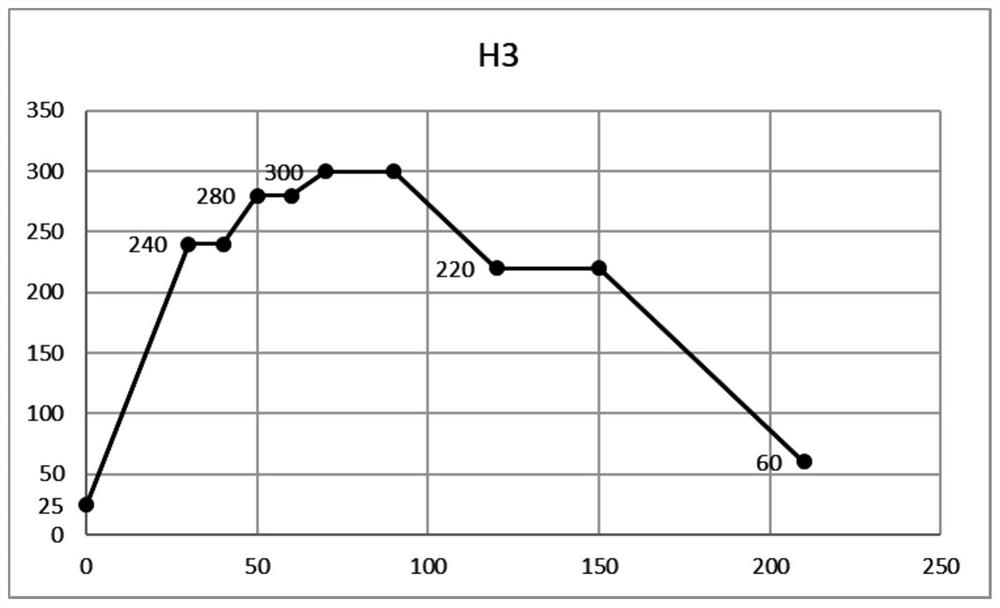

Image

Examples

Embodiment 1

[0033] Sample Preparation:

[0034]Weigh 15g of PPS (polyphenylene sulfide, Xinhecheng 3450S), 60g of white corundum 320 mesh, and 25g of white corundum 600 mesh. Mix in a small pulverizer for 10 seconds and set aside.

[0035] 10 g of the mixed sample was weighed, and hot-pressed in a circular mold with a diameter of 50 mm and a heating mantle at a pressure of 100 MPa, a mold core temperature of 300° C., and a pressing time of 20 min.

[0036] After cooling, the sample was taken out, labeled as M1, and tested for thermal conductivity and density.

Embodiment 2

[0038] Weigh 10g of PPS (polyphenylene sulfide, Xinhecheng 11200F), 60g of white corundum 320 mesh, and 30g of white corundum 600 mesh. Mix in a small pulverizer for 10 seconds and set aside.

[0039] 10 g of the mixed sample was weighed, and hot-pressed in a circular mold with a diameter of 50 mm and a heating mantle at a pressure of 200 MPa, a temperature of 300° C., and a pressing time of 20 min.

[0040] After cooling, the sample was taken out, labeled as M2, and tested for thermal conductivity and density.

Embodiment 3

[0042] Weigh 10g of PPS (polyphenylene sulfide, Xinhecheng 11200F), 60g of white corundum 600 mesh, and 30g of white corundum 1200 mesh. Mix in a small pulverizer for 10 seconds and set aside.

[0043] 10 g of the mixed sample was weighed, and hot-pressed in a circular mold with a diameter of 50 mm and a heating mantle at a pressure of 200 MPa, a temperature of 300° C., and a pressing time of 20 min.

[0044] After cooling, the sample was taken out, labeled M3, and tested for thermal conductivity and density.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com