Multi-shaft motor with multiple extension torques and multiple output rotating speeds

A shaft motor, multi-output technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems that it is difficult for the motor to be suitable for various working conditions, output torque and output speed range are limited, etc., to improve applicability and practicality sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

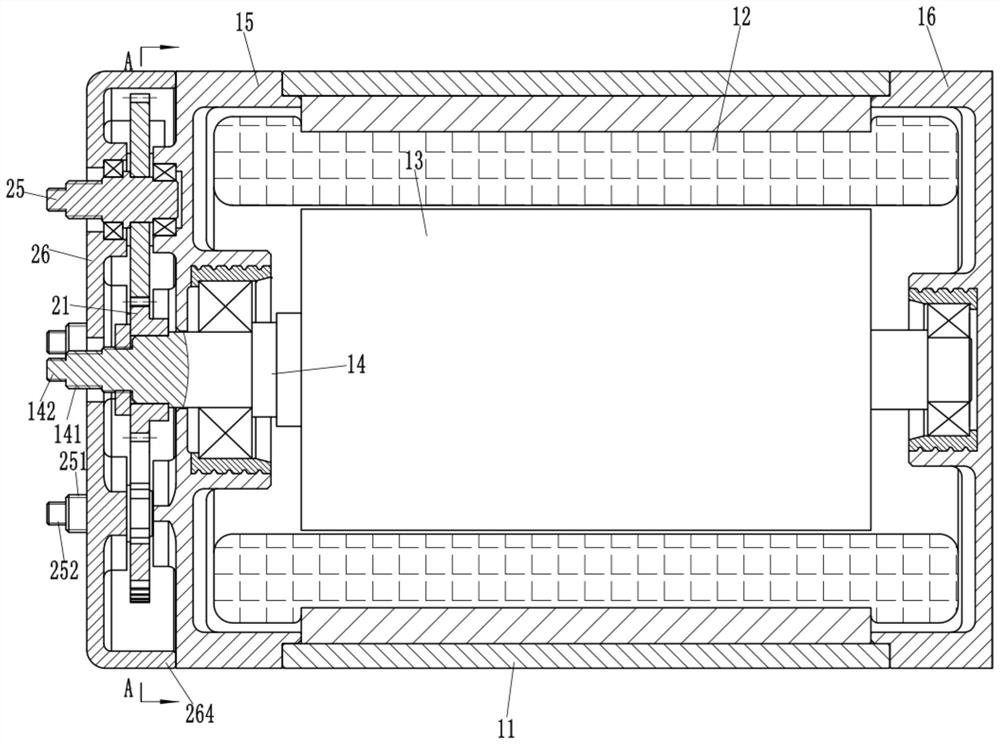

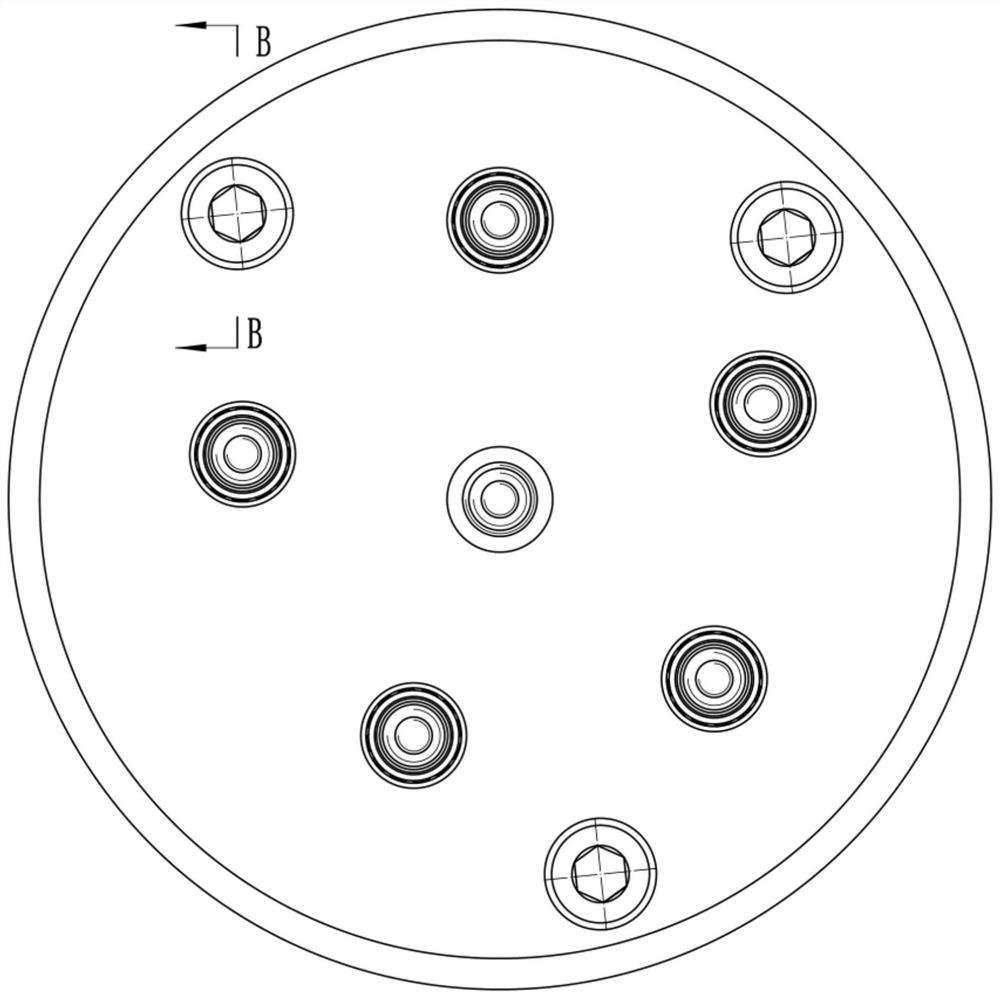

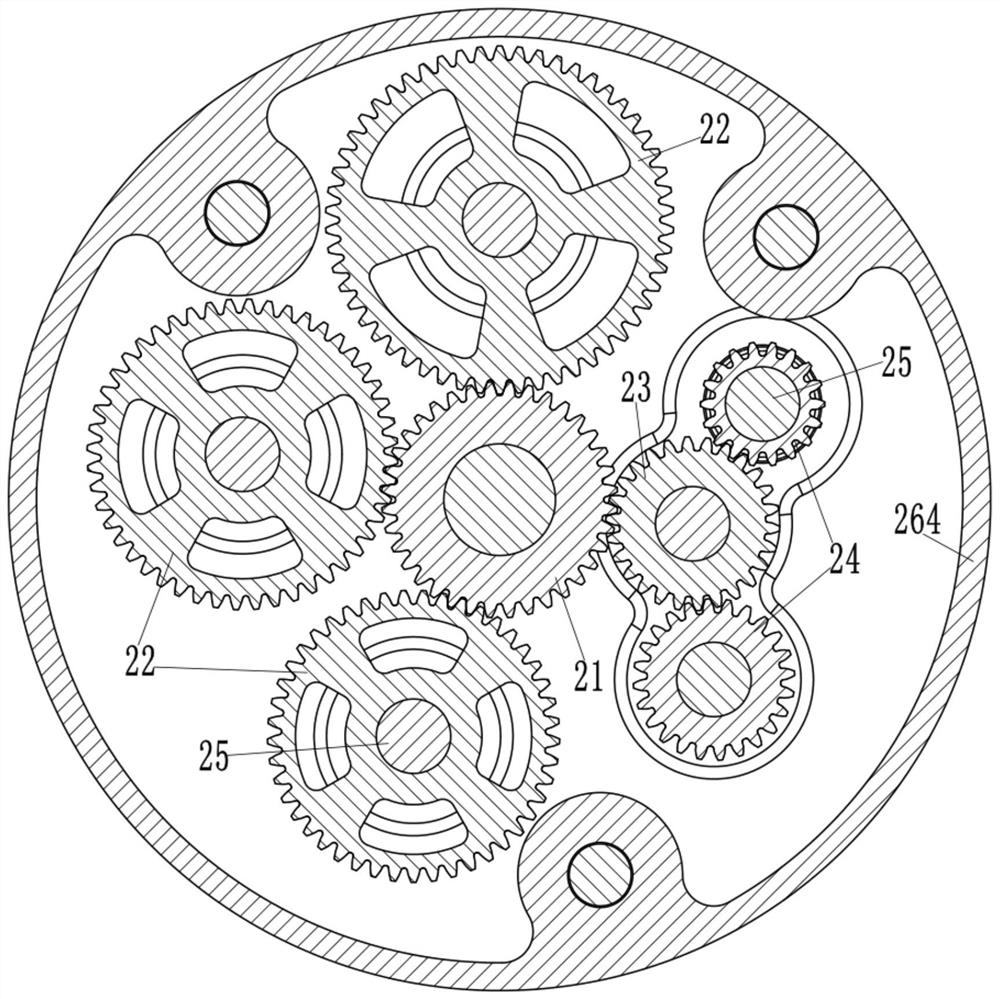

[0016] Examples, see e.g. Figure 1 to Figure 4 As shown, a multi-axis motor with multiple output torques and multiple output speeds includes a motor housing 11, a stator 12 is fixed inside the motor housing 11, a rotor 13 is sleeved inside the stator 12, and the motor of the rotor 13 The two ends of the shaft 14 are respectively hinged on the front end cover 15 and the rear end cover 16 which are fixedly connected with the motor housing 11; A plurality of torque increasing gears 22 and an idler gear 23 are meshed on the outer side of the idler gear 23, and a plurality of speed increasing gears 24 are meshed on the outer side of the idler gear 23, and a plurality of torque increasing gears 22 and a plurality of speed increasing gears 24 are respectively fixed on corresponding output shafts 25, the two ends of the output shaft 25 are respectively hinged on the front end cover 15 and the gear case cover 26, and the idler 23 is hinged on the front end cover 15 and the gear case c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com