Fire hose placement device of fire fighting truck

A technology for fire hoses and fire trucks, applied in fire rescue and other directions, can solve the problems of cumbersome operation and inconvenience in taking fire hoses, and achieve the effect of increasing the control method and increasing the speed of taking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

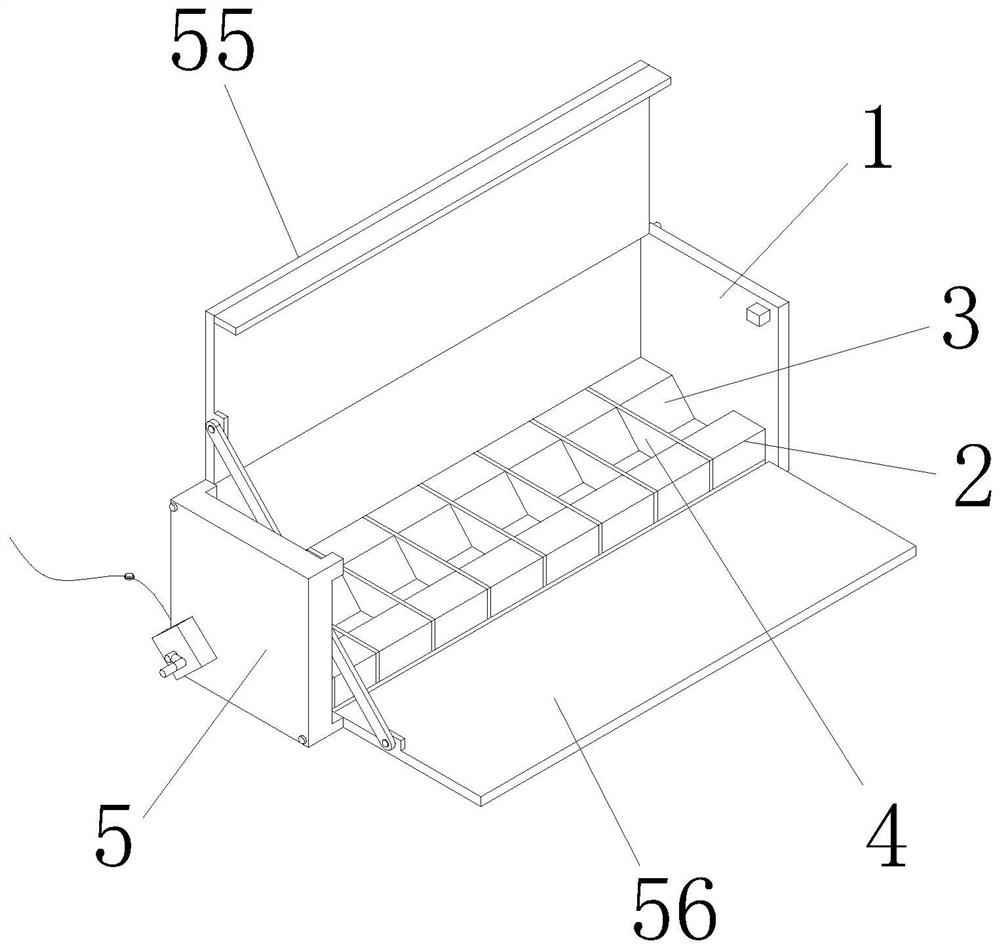

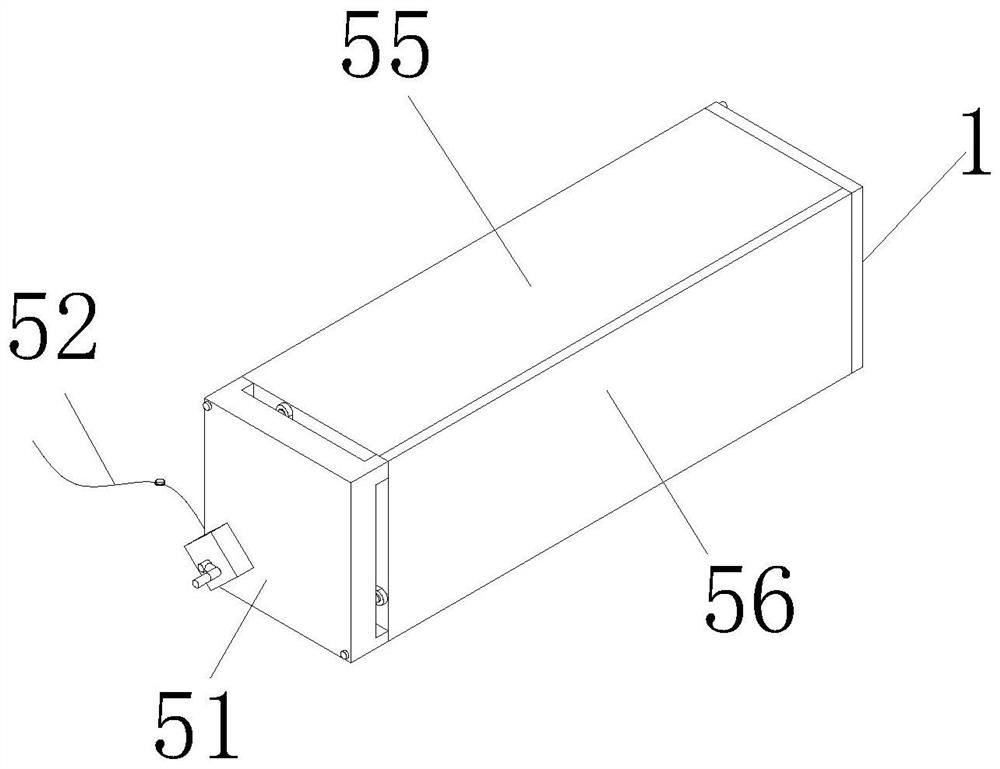

[0028] see figure 1 and figure 2 , the present invention provides a fire hose placement device for a fire truck through improvement, including a casing 1 and an opening and closing device 5. The inner bottom of the casing 1 is locked with the support seat 2 by bolts, and a concave hole is opened in the middle of the support seat 2. Groove 3, and a partition plate 4 is vertically arranged inside the groove 3, the left side of the shell 1 is locked with the opening and closing device 5 by bolts, the inner wall of the groove 3 is smooth, and the length of the groove 3 is from top to Lower taper for easy placement and support of fire hose.

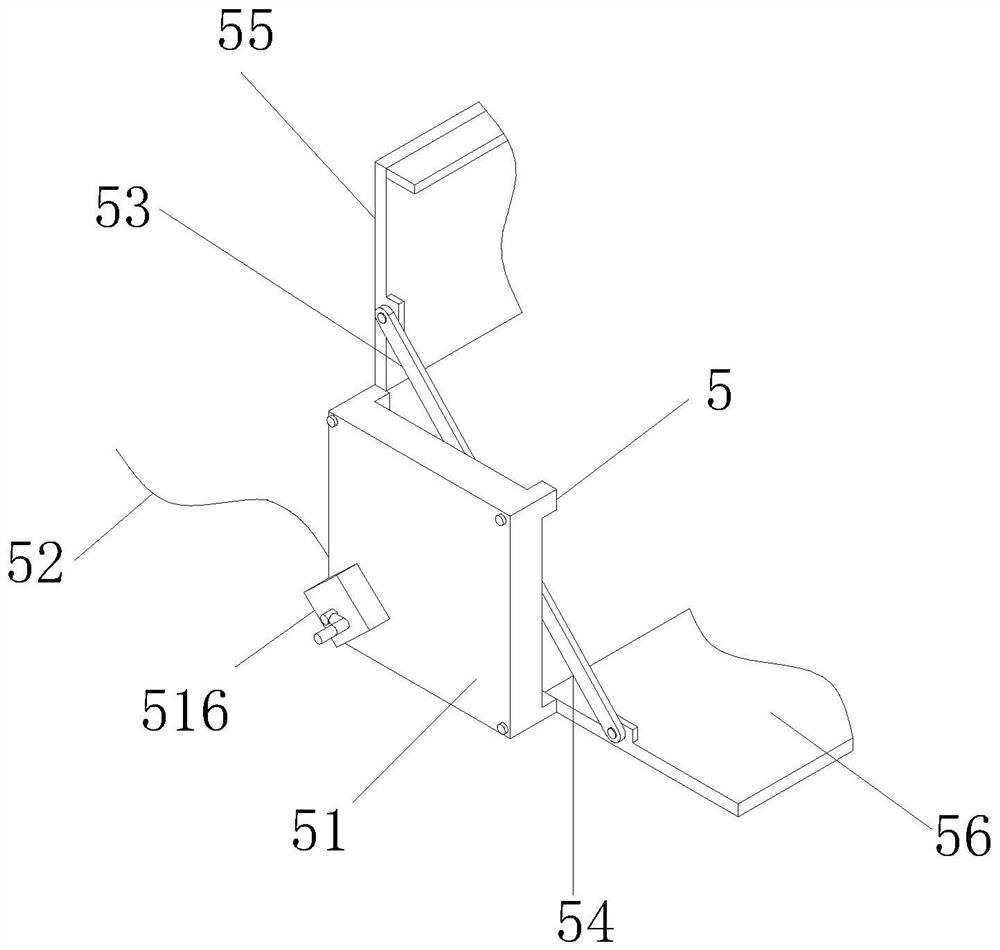

[0029] see image 3 , the present invention provides a fire hose placement device for a fire truck through improvement. The opening and closing device 5 includes a control mechanism 51, a power cord 52, a first connecting rod 53, a second connecting rod 54, an upper cover 55 and a The cover plate 56, the rear end of the control mechanism 5...

Embodiment 2

[0033] The present invention provides a fire hose placement device for a fire truck through improvement. The second connecting rod 54 is arranged obliquely, and the second connecting rod 54 is inclined downward from back to front, so that the movable shaft 514 passes through when moving downward. The second connecting rod 54 pulls the front cover 56 to rotate downwards, the left and right sides of the upper cover 55 and the front cover 56 are smooth, and the inner wall of the housing 1 is bonded to the upper cover 55 and the front cover 56. The upper cover 55 and the front cover 56 close the top end and the front side of the casing 1 .

[0034]The present invention provides a fire hose placement device for a fire truck through improvement, and its working principle is as follows;

[0035] First, before use, first install the shell 1 of the device on the required fire truck, and connect the power line 52 with an external control device with a power supply, and control the motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com