Storage supporting system for logistics robots

A logistics robot and robot technology, applied in the field of logistics warehousing, can solve the problems of large robot operation site space, high operating cost and maintenance cost, and inconvenient safe delivery of goods, so as to reduce collision and grabbing, speed up the picking speed, The effect of improving shipping efficiency and delivery speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

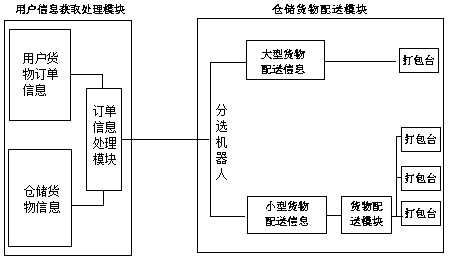

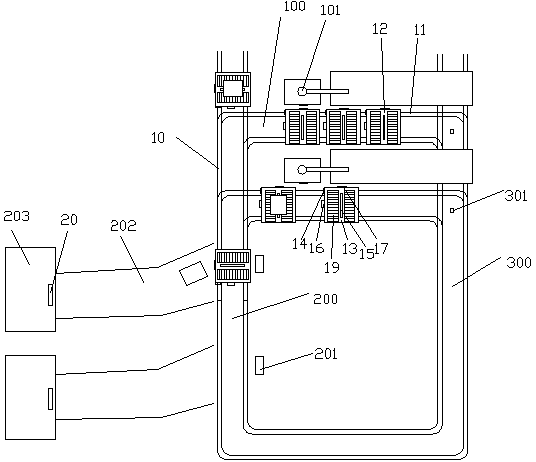

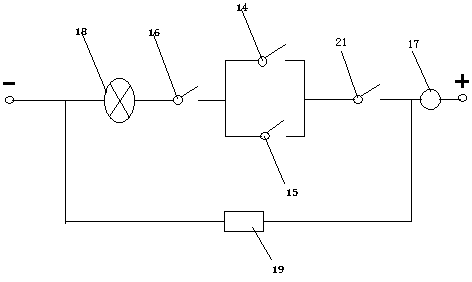

[0022] The technical scheme of this patent is further elaborated now in conjunction with accompanying drawing, figure 1It is an embodiment of the warehousing supporting system for logistics robots of the present invention, including a user information acquisition processing module and a warehouse goods distribution module, the user information acquisition processing module and the warehouse goods delivery module are connected by electrical signals; the user information acquisition processing module The module includes the user's goods order information, warehouse goods information and order information processing module. The order information processing module compares the user's goods order information with the warehouse goods information, and through the order information processing module, the goods on the order are classified, packaged and delivered, and sent to the warehouse The goods distribution module, through the modular information processing structure, converts the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com