A stamping type automatic stamping machine

An automatic stamping machine, stamping technology, applied in stamping, printing, etc., can solve the problems of ink pad tank polluting paper, unclear stamps, cumbersome work, etc., to achieve the effect of reducing rubbing, avoiding paper pollution, and running smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT OF THE INVENTION The specific embodiments of the present invention will be described in detail below, but it should be understood that the scope of the invention is not limited by the specific embodiments. Based on the embodiments in the present invention, all other embodiments obtained without making creative labor without making creative labor.

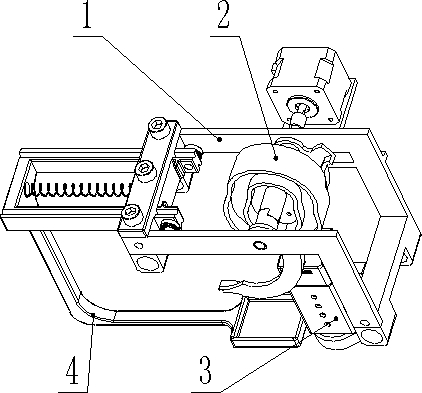

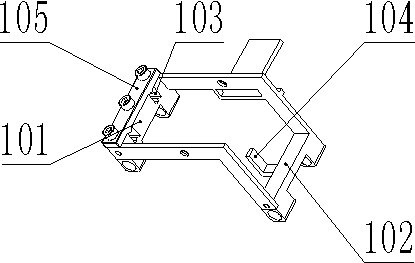

[0029] The present invention provides a stamping automatic stamp machine, such as Figure 1-7 include:

[0030] Bracket 1;

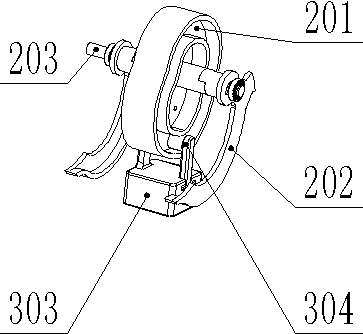

[0031] The stamp mechanism 2, including the double-sided geometric closed groove cam 201 and two curved members 202 provided on both sides of the groove cam 201, the groove cam 201 has two pushers, the groove cam 201 And the two curved members 202 are fixed to the rotating shaft 203, and one side opposite to the two curved members 202 is provided with an arcuate guide along its arc direction, the rotating shaft 203 is disposed on the stent 1, and the shaft 203...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com