Vehicle damping device

A shock absorbing device and vehicle technology, which is applied to vehicle components, transportation and packaging, elastic suspension, etc., can solve the problems of poor shock absorbing effect and reduced passenger ride comfort, so as to improve shock absorbing performance, improve ride comfort, The effect of weakening the fluctuation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

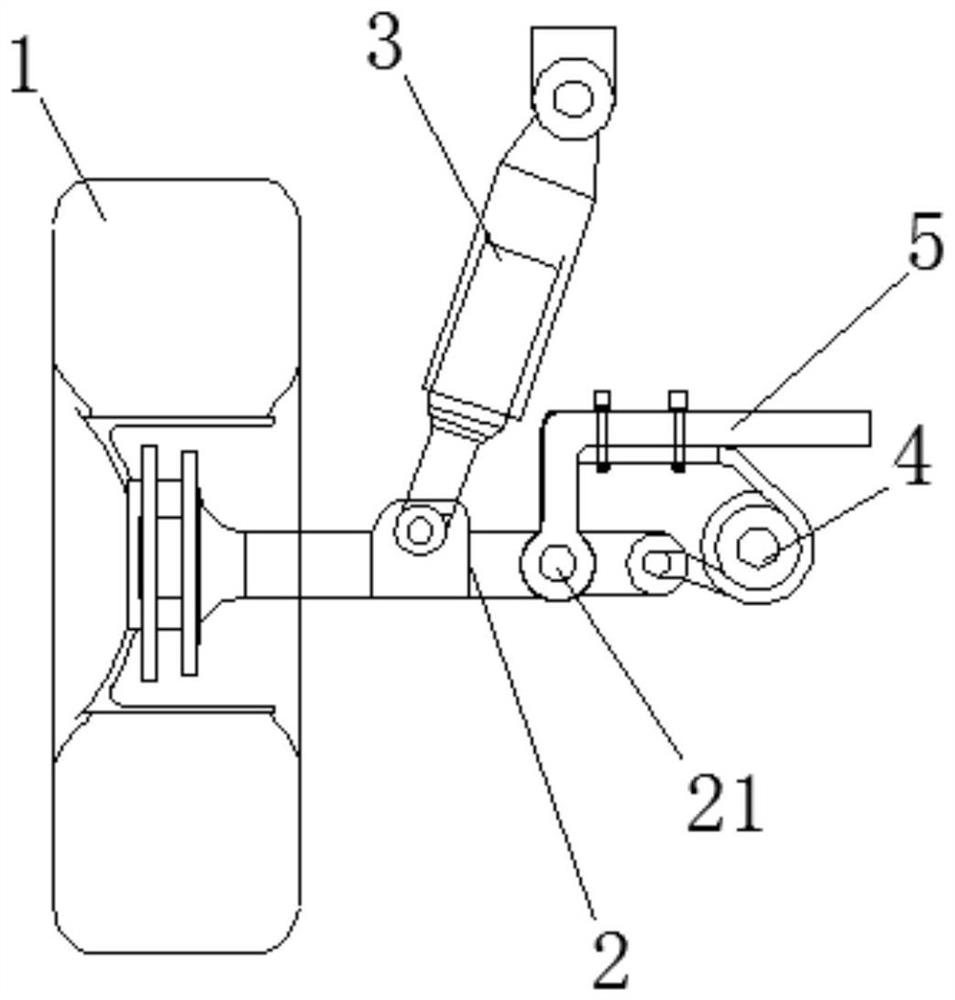

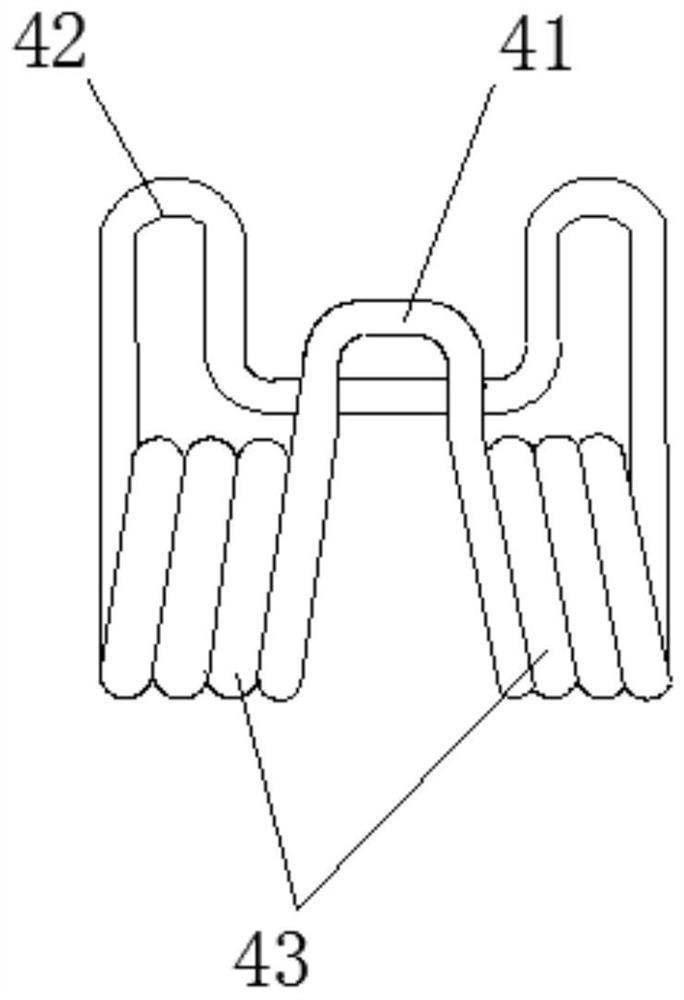

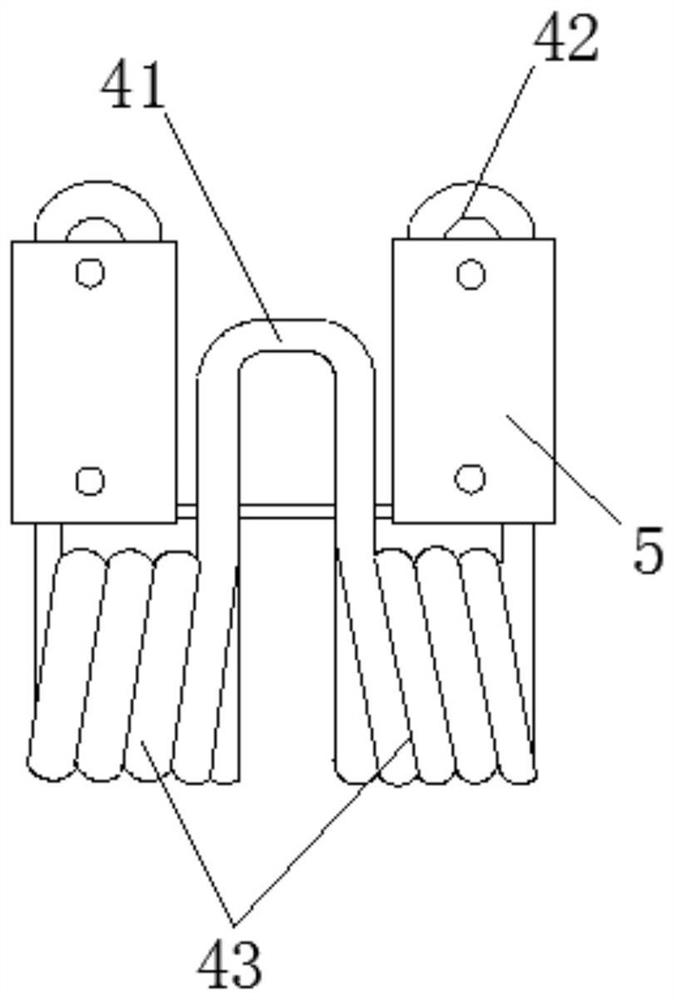

[0018] Such as figure 1 As shown, the axle housing 2 of the vehicle is coaxially sleeved on the axle of the tire 1, and the vehicle shock absorber is installed between the axle housing 2 and the chassis frame 5, thereby weakening and eliminating the vibration generated by the tire 1, thereby reducing the impact on the vehicle. The impact of the body, to ensure smooth operation. The axle end extending from the chassis frame 5 to the axle housing 2 is connected to the axle housing 2 through a pin, thereby forming a connecting fulcrum 21 . The connecting fulcrum 21 is the central axis of the shock absorbing device, and the axle housing 2 and the chassis frame 5 can swing at a certain angle with the connecting fulcrum 21 as the axis. The outer shock absorber 3 and the inner shock absorber 4 of the shock absorber are respectively arranged on both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com