Suction disk loading device and core vibration abatement and core anti-vibration method

A loading device, inhalation technology, applied in the direction of poor vibration/sound insulation/absorption, recording information storage, instruments, etc., can solve problems such as large appearance size, high cost of grease shock pads, and disc loading device not working properly. , to achieve the effect of wide application space and good shock absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] (Embodiment 1, the core shock absorber assembly of the suction type disk loading device)

[0065] See Figure 13 to Figure 21 , the core shock absorber assembly of the suction disk loading device has a shock absorber 81, a shock absorber connecting seat 82 and two shock absorbing connectors 83; the shock absorbing connecting seat 82 has a mounting body 822, a connecting body 821 and a positioning body 823; The shock-absorbing connector 83 is a stepped cylinder with a fixed portion 831 and an embedding body 832; the embedding body 832 is composed of an embedding head portion 832-1 and an embedding neck portion 832-2; the diameter of the embedding head portion 832-1 is larger than The diameter of the embedding neck 832-2 is provided with a chamfer 832-3 at its axial outer end; the fixing part 831 has a stepped cylindrical head. The shock absorber 81 is an integral part made of elastic material, its basic shape is cylindrical or drum-shaped, and its inside is provided wit...

Embodiment 2

[0068] (Embodiment 2, the movement shock-absorbing device of suction type disc loading device)

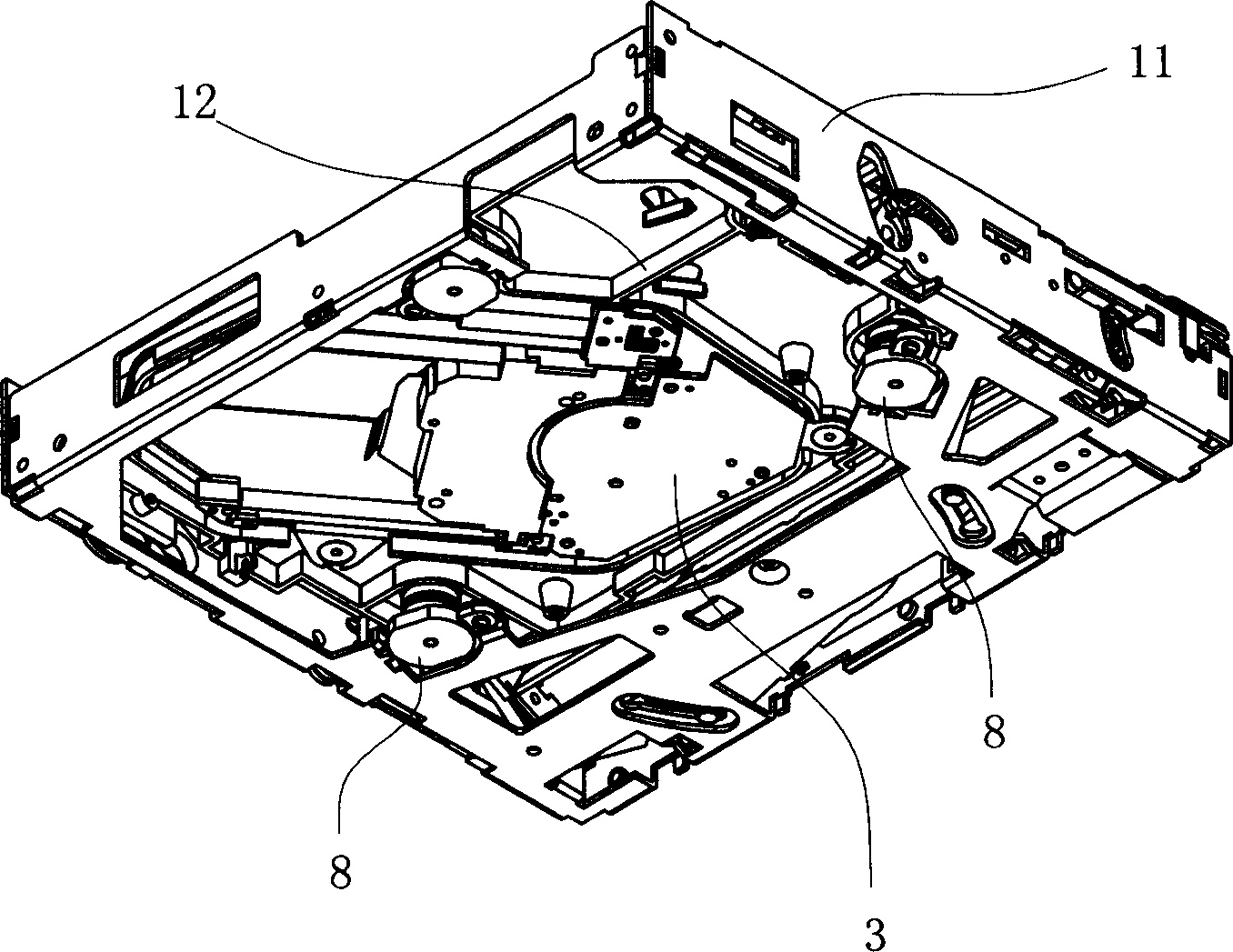

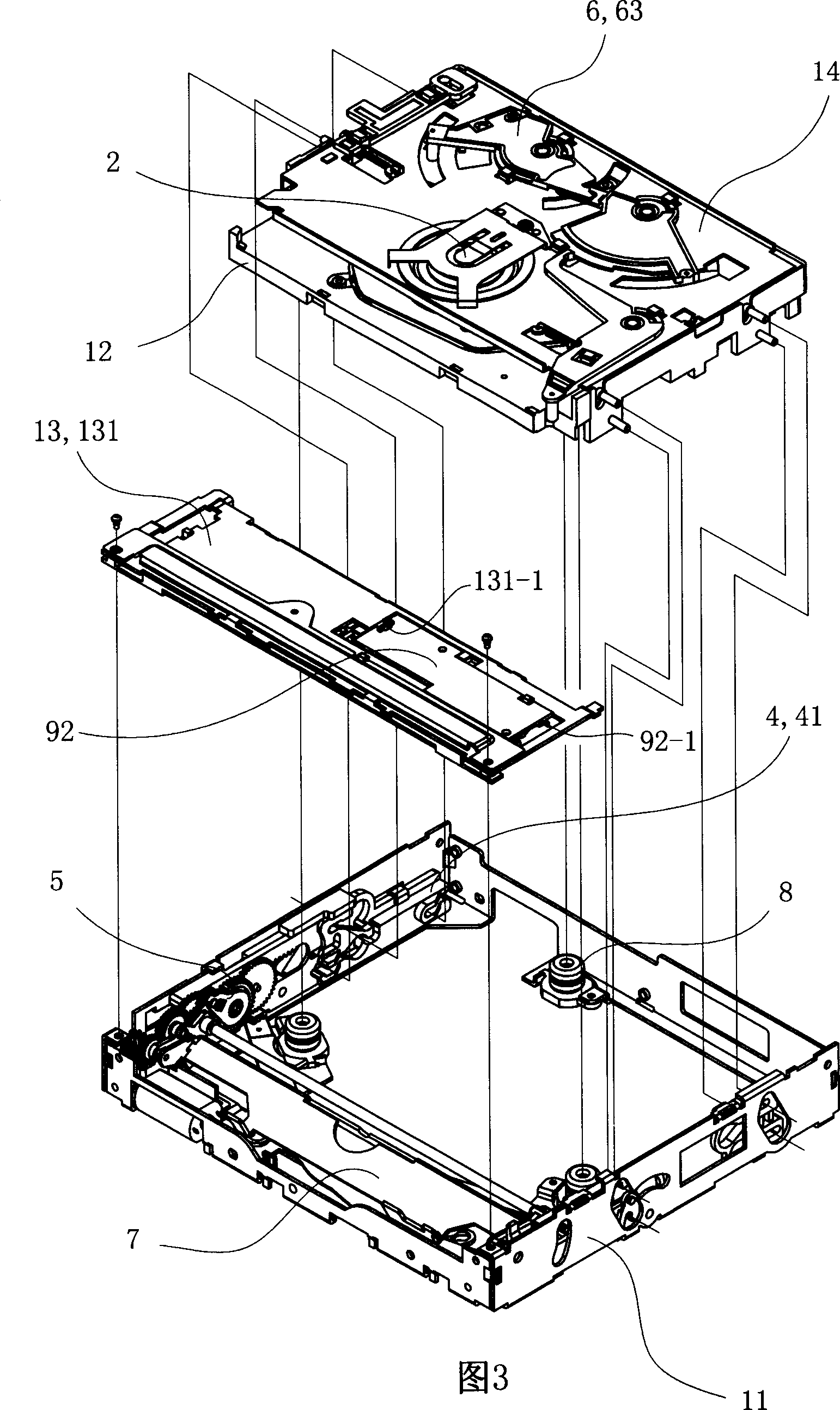

[0069] See Figures 10 to 21 and Figure 25 , Figure 26 , the movement shock-absorbing device of suction-type disk loading device has 3 to 4 groups of shock-absorbing assemblies 8, base 11 and optical pick-up drive part 3; Each group of shock-absorbing assemblies 8 has a shock-absorbing pad 81 respectively; The movement The shock absorber also has a mount 12; the base of the optical pickup driving part 3 is provided with 3 to 4 mounting feet 31, and each mounting foot 31 is provided with a mounting hole; the mount 12 is a plastic integral part, and the middle part is provided with The middle space that matches with the optical pickup driving part 3 through up and down; the installation base 12 is provided with the same mounting column 12-7 with the same number of mounting feet on the base of the optical pickup driving part 3 around the middle space; The mounting base 12 is also...

Embodiment 3

[0072] (Embodiment 3, Suction Type Disk Loading Device)

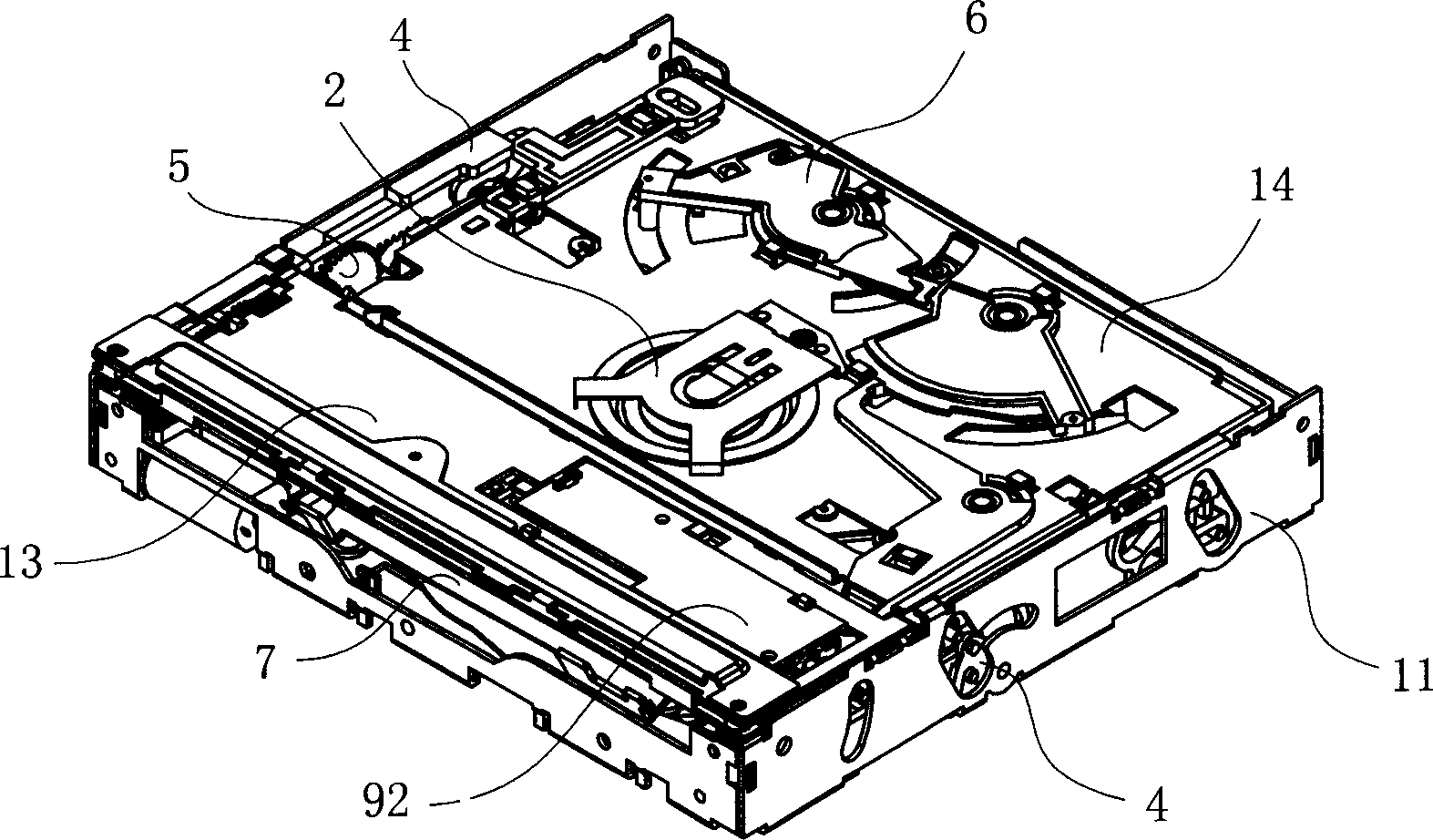

[0073] See Figure 1 to Figure 2 , The suction disk loading device has a base 11, a platen assembly 13, a control assembly 4, a transmission assembly 5, a guide roller assembly 7, a platen assembly 2, an optical pickup driving part 3 and 3 to 4 groups of shock absorbing assemblies 8.

[0074] See Figure 12 , The optical pickup driving part 3 is provided with a base, and the base is provided with 3 to 4 mounting feet 31, and each mounting foot 31 is provided with a mounting hole.

[0075] See Figure 25 and Figure 26, the base 11 has a front side plate 111, a rear side plate 112, a left side plate 113, a right side plate 114 and a bottom plate 115; the front part of the base 11 is provided with a guide roller assembly mounting part 116 with an upward installation direction, and the guide roller assembly The installation part 116 has the left guide roller shaft groove 116-1 with the opening upwards arranged on the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com