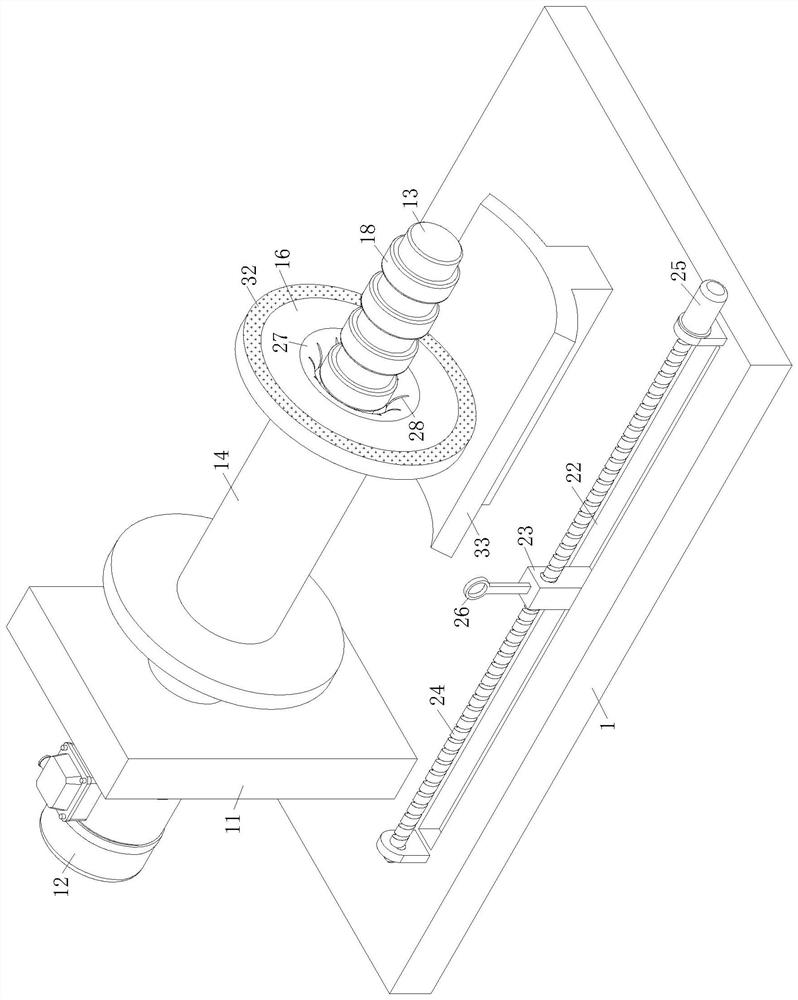

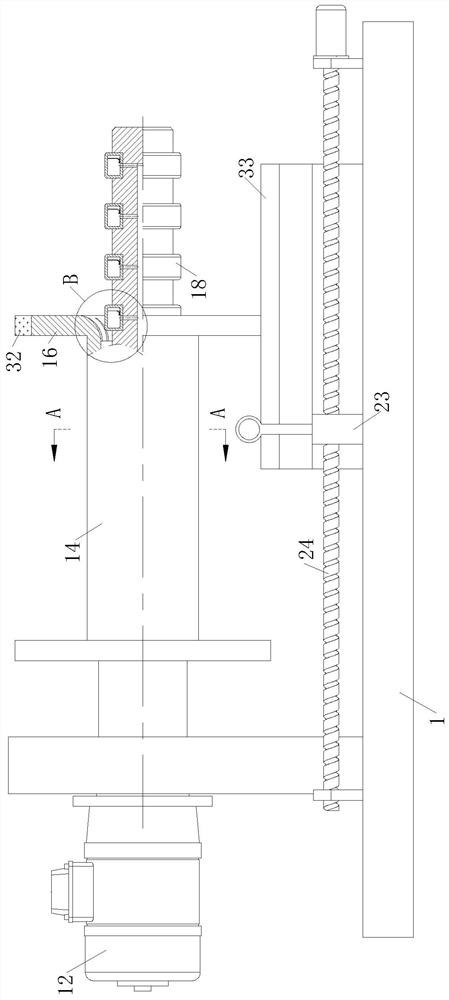

A textile yarn winding device

A winding device and textile yarn technology, which is applied in the directions of transportation and packaging, thin material handling, and delivery of filamentous materials, etc. It can solve the time-consuming and labor-consuming installation and removal of the winding roller and affect the winding efficiency of the winding device and other problems, to achieve the effect of increasing the fixed effect, reducing the circular jump, and increasing the transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

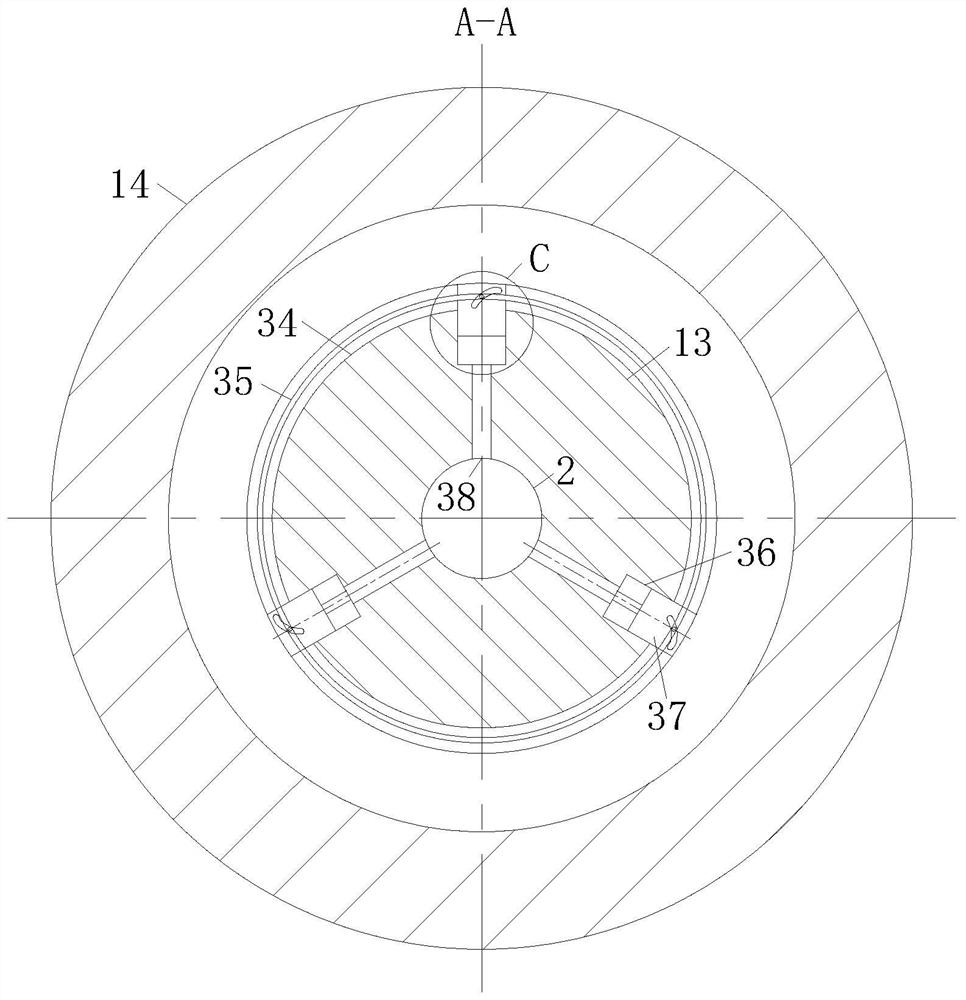

[0024] As an embodiment of the present invention, the end of the No. 1 hole 15 close to the elastic ring 18 is provided with an arc-shaped chamfer 27, and a set of friction grooves 28 are evenly distributed on the inner circumference of the chamfer 27, and the chamfer 27 cooperates with friction The groove 28 reduces the wear of the elastic ring 18 and prolongs the service life of the elastic ring 18; through the arc-shaped chamfer 27, the extrusion of the edge of the first hole 15 on the elastic ring 18 is reduced, thereby further reducing the excessive bending of the elastic ring 18 Deformation increases the service life of the elastic ring 18, and the chamfer 27 cooperates with the friction groove 28, so that the elastic ring 18 expands and embeds in the friction groove 28, thereby increasing the friction between the elastic ring 18 and the winding roller 14, and reducing the elastic ring 18 The wear caused by relative sliding with the winding roller 14 increases the rotatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com