Opening defect detection device of weaving machine

A detection device and defective technology, which is applied in looms, textiles, textiles and papermaking, etc., can solve the problems of inability to correctly detect the defective opening of warp yarn groups and difficult image processing, and achieve the effect of easy image processing and high-precision detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

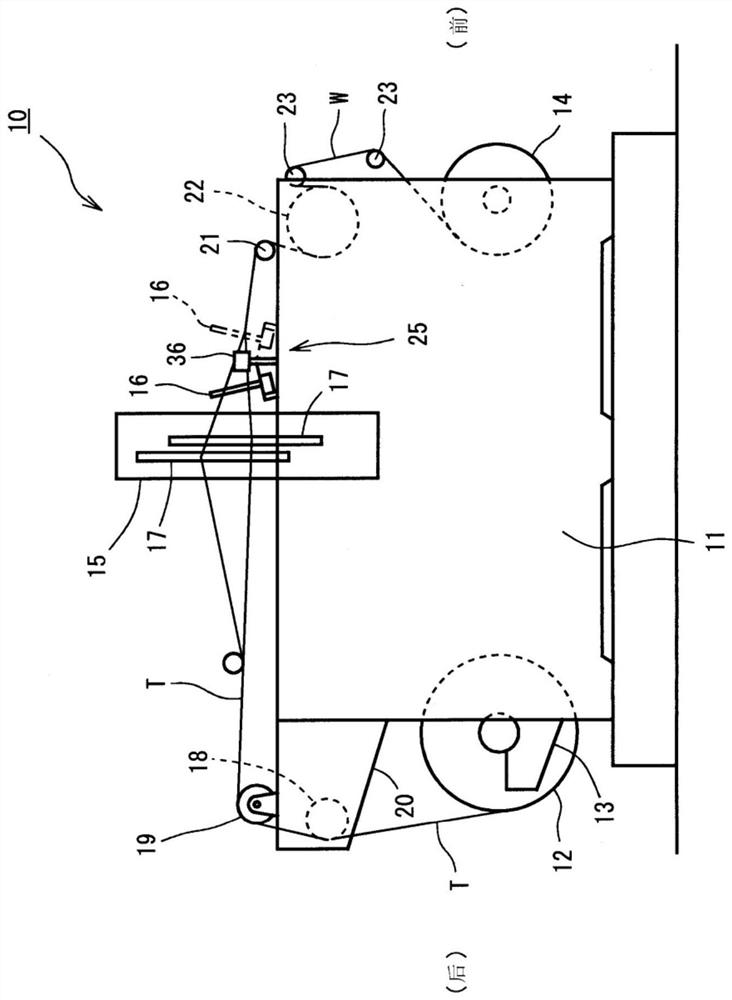

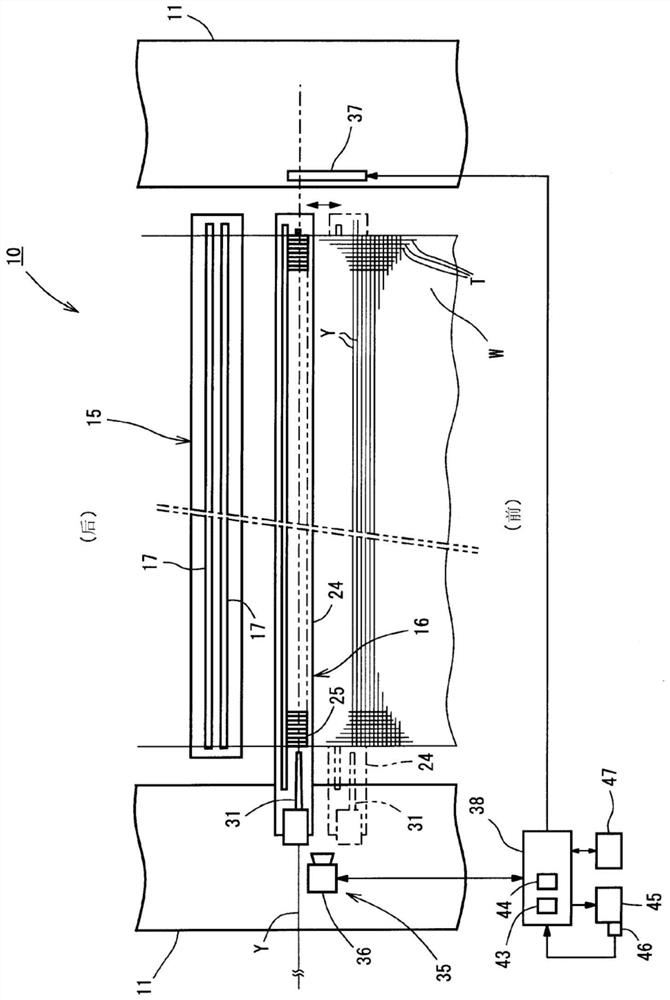

[0025] Hereinafter, a shedding failure detection device for a loom according to a first embodiment will be described with reference to the drawings. First, a loom provided with a shedding failure detection device will be described.

[0026] figure 1 The shown loom 10 is an air-jet loom that flies weft yarns by compressed air and inserts weft yarns to openings of warp yarn T groups. Such as figure 2 As shown, the loom 10 includes a pair of left and right side frames 11 . exist figure 1 , only one side frame 11 is shown. A warp beam 12 is provided at the rear of the loom 10 . The warp beams 12 are supported by beam supports 13 fixed at the rear of the side frames 11 . A plurality of warp yarns T are wound around the warp beam 12 over the width direction. A beam 14 supported by a side frame 11 is provided at the front of the loom 10 . The beam 14 is used for winding the fabric W to be woven.

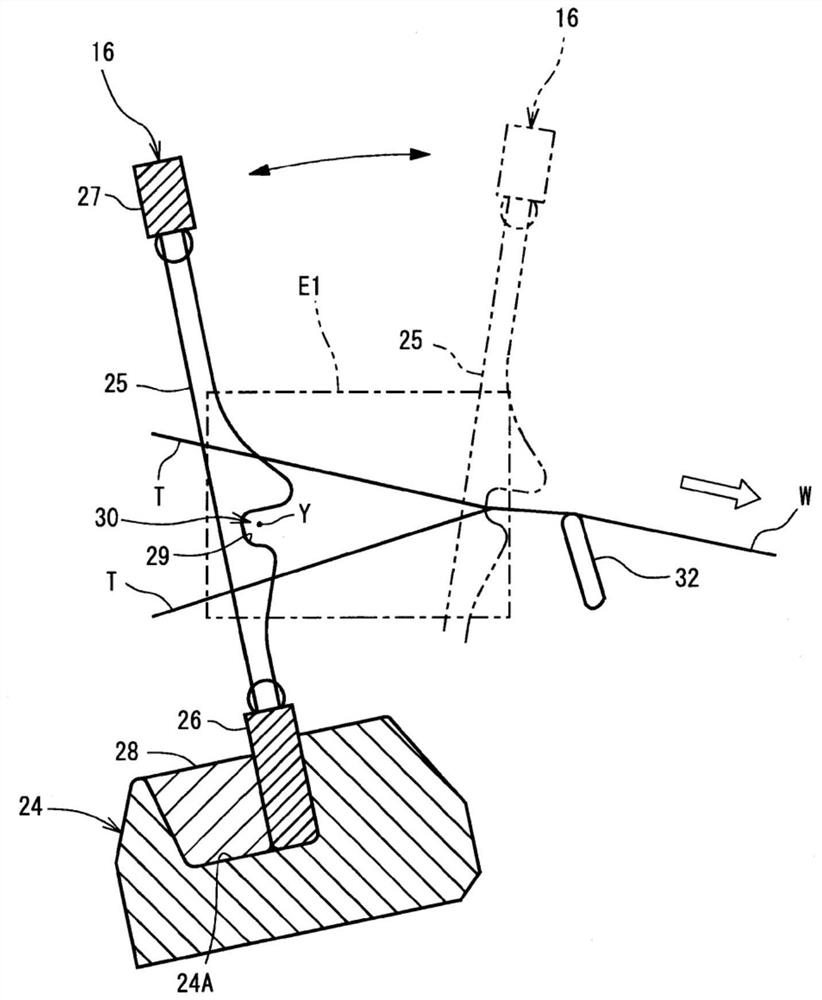

[0027] The loom 10 includes a warp yarn shedding device 15 for shedding a gro...

no. 2 Embodiment approach

[0054] Next, a shedding failure detection device for a loom according to a second embodiment will be described. This embodiment differs from the first embodiment in that the camera is disposed behind the heald frame in the front-rear direction of the warp yarn group. In this embodiment, the description of the first embodiment is applied to the same configuration as that of the first embodiment, and common reference numerals are used.

[0055] Such as Figure 7 As shown, the shedding defect detection device 50 of the loom 10 has a camera 51 for photographing the shedding of the warp yarn T group, a light irradiator 52 for observing the background of the warp yarn T group shedding from the camera 51, and a control for detecting the shedding defect of the warp yarn T group. Device 38.

[0056] The camera 51 has the same structure as the camera 36 of the first embodiment. In the front-rear direction of the warp yarn T group, the camera 51 is arranged on the delivery side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com