A method for determining the amount of asphalt in the gravel seal layer in the embedded ultra-thin wear layer

A technology of asphalt dosage and gravel sealing layer, applied in the direction of on-site coagulation pavement, roads, buildings, etc., can solve the problem of oil flooding, inability to accurately distinguish between connected and non-connected gaps in large-void wear layers, and oil flooding diseases and other problems to achieve the effect of accurate and efficient testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

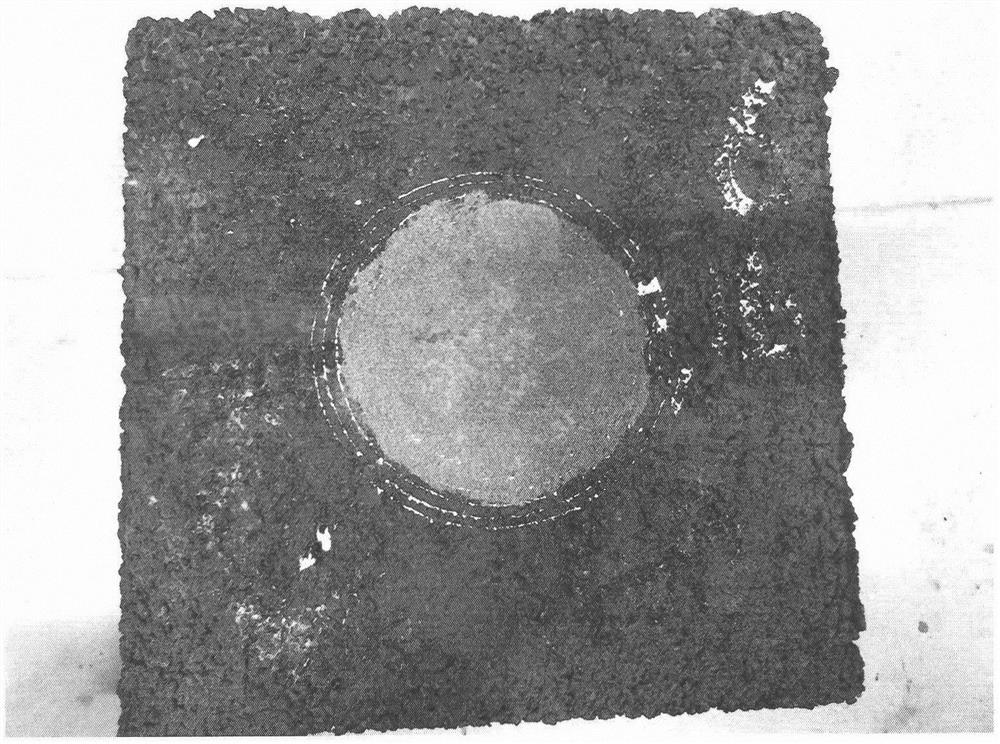

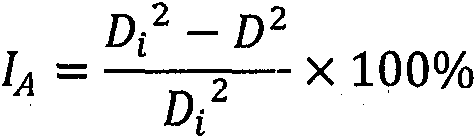

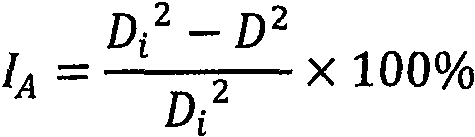

[0020] In order to overcome the problem that the existing theoretical calculation formulas cannot fully consider the differences of actual samples, resulting in the possible excessive amount of bitumen used in the embedded ultra-thin wear layer. It has been found in practice that when the amount of asphalt used in the gravel seal layer under the embedded ultra-thin wearing layer is too large, the asphalt will overflow to the surface of the asphalt concrete with large voids in the upper layer to fill the surface macroscopic texture, resulting in a decrease in the surface macroscopic texture. Based on this, The invention uses the testing principle of the asphalt pavement structure depth to characterize whether the amount of asphalt in the gravel seal layer in the embedded ultra-thin asphalt concrete is excessive through the change of the surface structure depth of the large-void asphalt concrete. Furthermore, due to the variability of the upper layer of large-void asphalt concret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com