Wear-resistant bearing

A wear-resistant bearing and bearing technology, applied in the field of wear-resistant bearings, can solve the problems of inconvenient addition of lubricating oil to wear-resistant bearings, inconvenient installation and use of wear-resistant bearings, inconvenient disassembly and replacement, etc., so as to avoid bearing wear and facilitate connection. Good stability and lubricating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

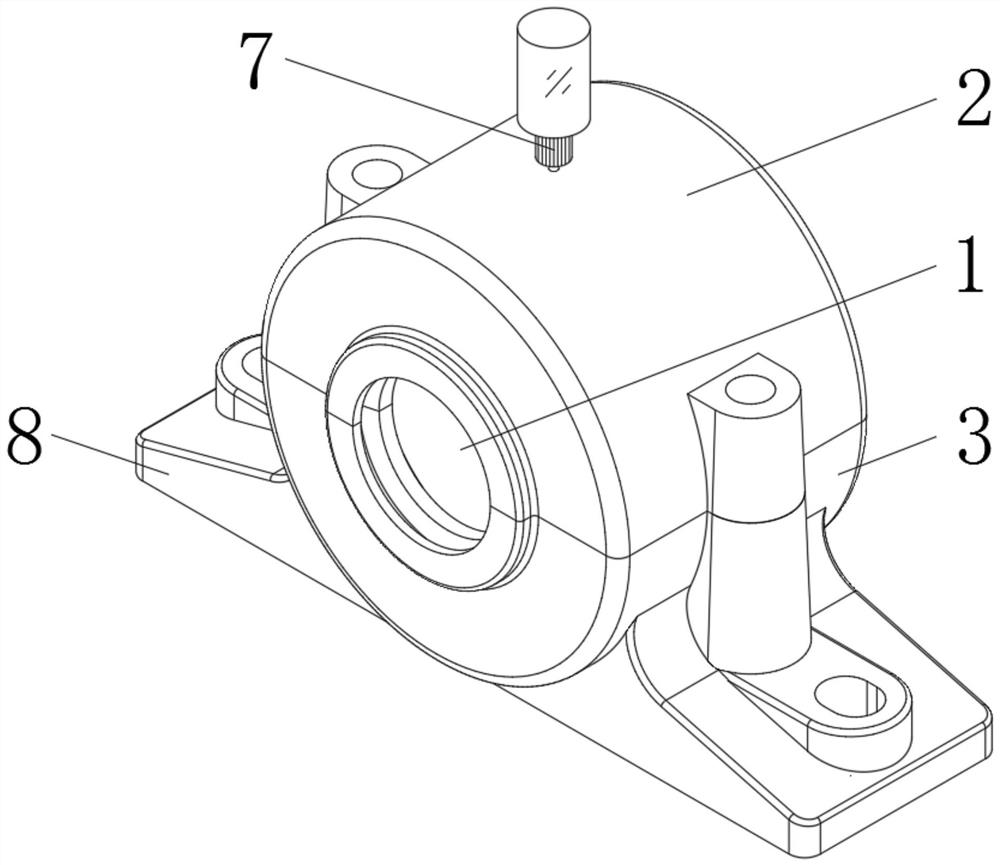

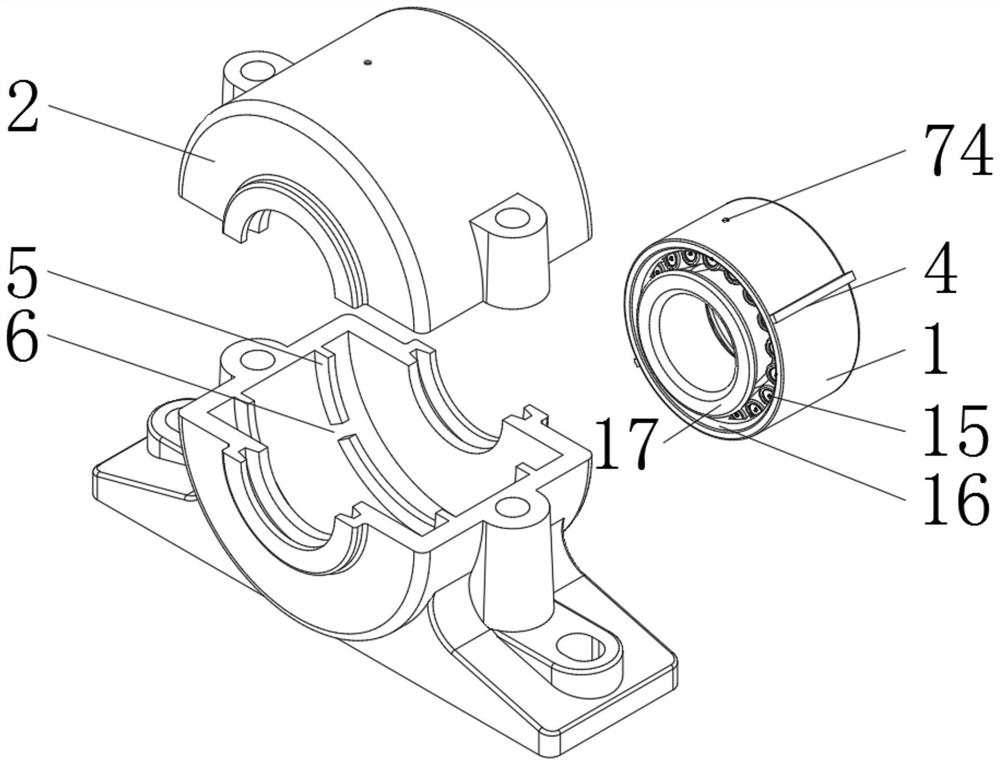

[0036] Such as figure 1 As shown, a wear-resistant bearing includes a bearing body 1, an upper connecting shell 2 is arranged on the upper end of the bearing body 1, a lower connecting shell 3 is arranged on the lower end of the upper connecting shell 2, and a connecting bar 4 is arranged on the outer surface of the bearing body 1. , the outer surface of the inner wall of the upper connecting shell 2 and the lower connecting shell 3 is provided with a connecting ring 5, the outer surface of the connecting ring 5 is provided with a connecting opening 6, and the upper end of the upper connecting shell 2 is provided with a refueling structure 7, which includes a storage tank Oil bottle 71, connection cover 72, oil guide pipe 73, No. 1 diversion hole 74 and No. 2 diversion hole 75, the lower end of lower connecting shell 3 is provided with base 8, and the upper end of base 8 is provided with connecting block 9, connecting block 9 The upper end of the connecting block 9 is provided...

Embodiment 2

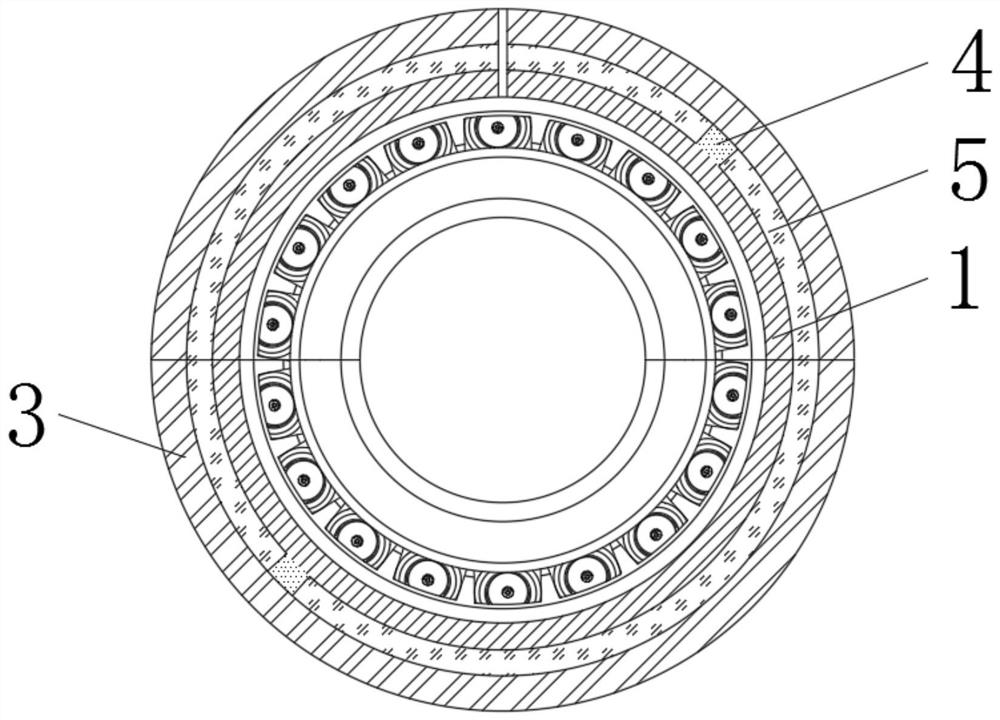

[0042] On the basis of Example 1, as figure 2 , 3 As shown, the connecting strip 4 is strip-shaped and is fixedly connected with the bearing body 1. The number of connecting rings 5 is several groups. The connecting rings 5 are made of alloy materials. The connecting rings 5 are connected to the upper connecting shell 2 and the lower connecting shell 3 are all fixedly connected, and the opening size of the connecting opening 6 matches the connecting strip 4, which is beneficial to the matching effect between the connecting opening 6 and the connecting strip 4.

Embodiment 3

[0044] On the basis of embodiment one and embodiment two, such as Figure 4 As shown, the No. 1 connecting column 11 is columnar and is fixedly connected with the lower connecting shell 3, the No. 2 connecting column 13 is fixedly connected with the upper connecting shell 2, and the No. 2 through hole 14 is connected through the No. 2 connecting column 13. The diameter of the second through hole 14 matches the diameter of the connecting hole 12, and the upper connecting shell 2 and the lower connecting shell 3 match, which is conducive to the stable connection between the first connecting column 11 and the lower connecting shell 3. Effect.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap