Detachable pipeline connector structure capable of adapting to geological sedimentation

A pipeline interface, detachable technology, applied in the direction of pipeline connection arrangement, hose connection device, pipe/pipe joint/pipe fitting, etc., can solve the problems of interface bursting, poor sealing performance of joints, and inability to disassemble, etc., to strengthen the shaft Improve the connection strength, improve the sealing performance, and avoid the effect of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

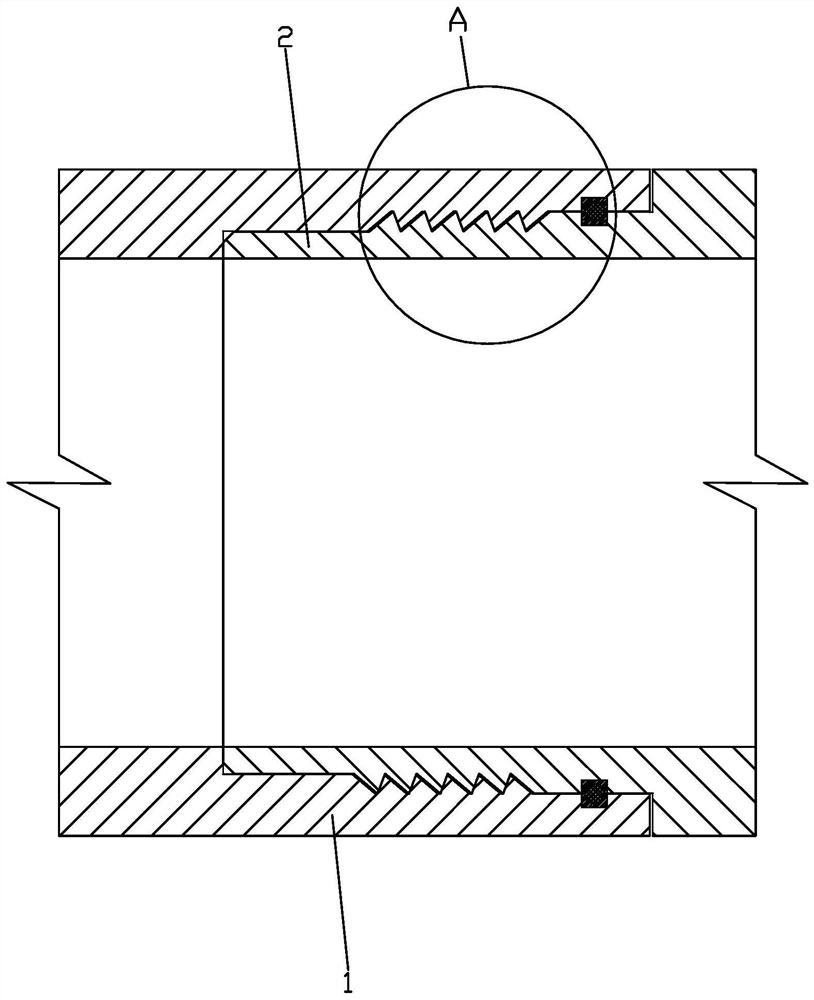

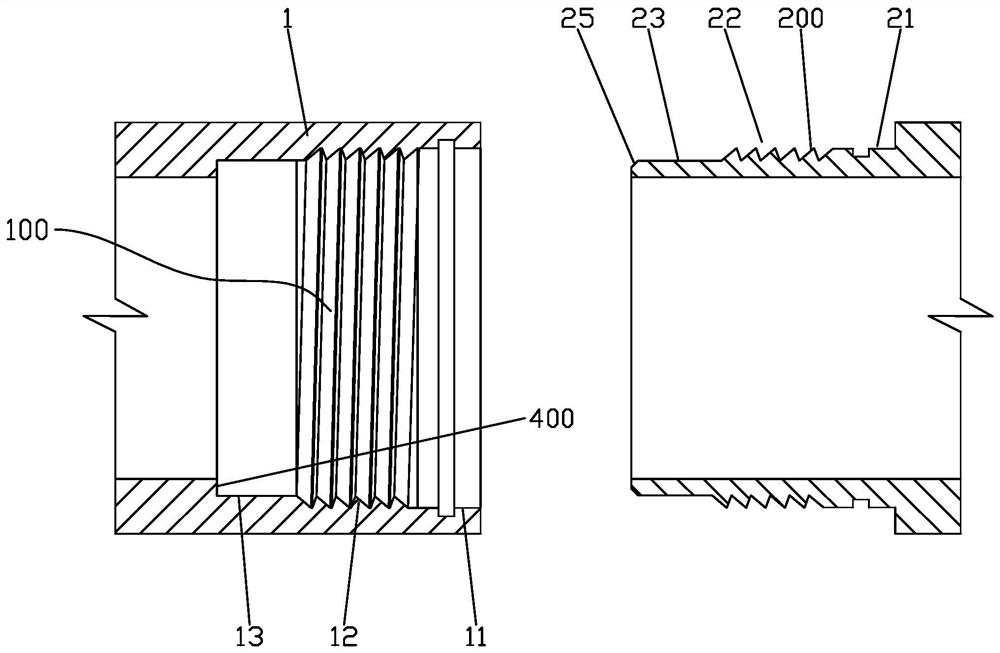

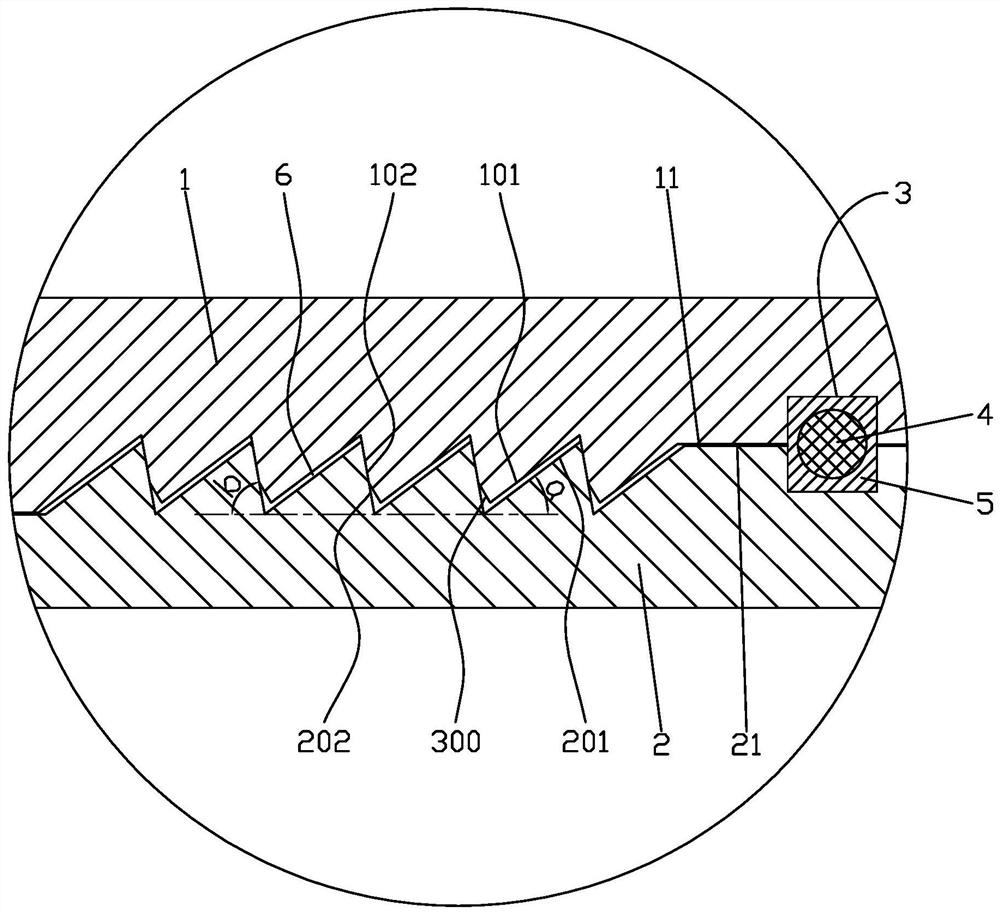

[0039] refer to Figure 1 to Figure 4, the present invention proposes a detachable pipeline interface structure that can adapt to geological subsidence, which includes a socket body, a socket body and a sealing ring 3; the right end of the socket body is provided with a socket section 1, and the socket section The inner wall of 1 is provided with a first flat wall section 11, a socket connection section 12, and a second flat wall section 13 arranged in sequence from right to left, and the socket connection section 12 is provided with an internal thread 100, and the thread of the internal thread 100 A first mating surface 101 is provided on the right side wall of the tooth, and a second mating surface 102 is provided on the left side wall of the thread of the internal thread 100; The socket section 2, the outer wall of the socket section 2 is provided with the third flat wall section 21 matching with the first flat wall section 11, the socket connecting section 22 matching with...

Embodiment 2

[0054] Figure 5 Embodiment 2 of the present invention is shown. This embodiment has a similar structure to Embodiment 1. The difference lies in: first, in this embodiment, the tooth shape of the external thread 200 is trapezoidal; second, in this embodiment , The socket connection section 22 is tapered, the diameter of the left end is smaller than the diameter of the right end, and the socket connection section 12 is tapered, and the diameter of the left end is smaller than the diameter of the right end. Adopting the tapered structure is more convenient for inserting the socket section 2 of one pipeline into the socket section 1 of the other pipeline to connect the two.

Embodiment 3

[0056] Figure 6 Embodiment 3 of the present invention is shown. This embodiment has a similar structure to Embodiment 1. The difference is that in this embodiment, the left side of the thread top of the internal thread 100 does not have the same structure as that in Embodiment 1. The first cutout 300 has a similar structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com