Optical anti-shake assembly

A technology of optical anti-shake and components, which is applied in the direction of optical components, optics, printing equipment, etc., can solve the problems of complex lens module structure and increased production cost, and achieve the effect of reducing production cost, reducing quantity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

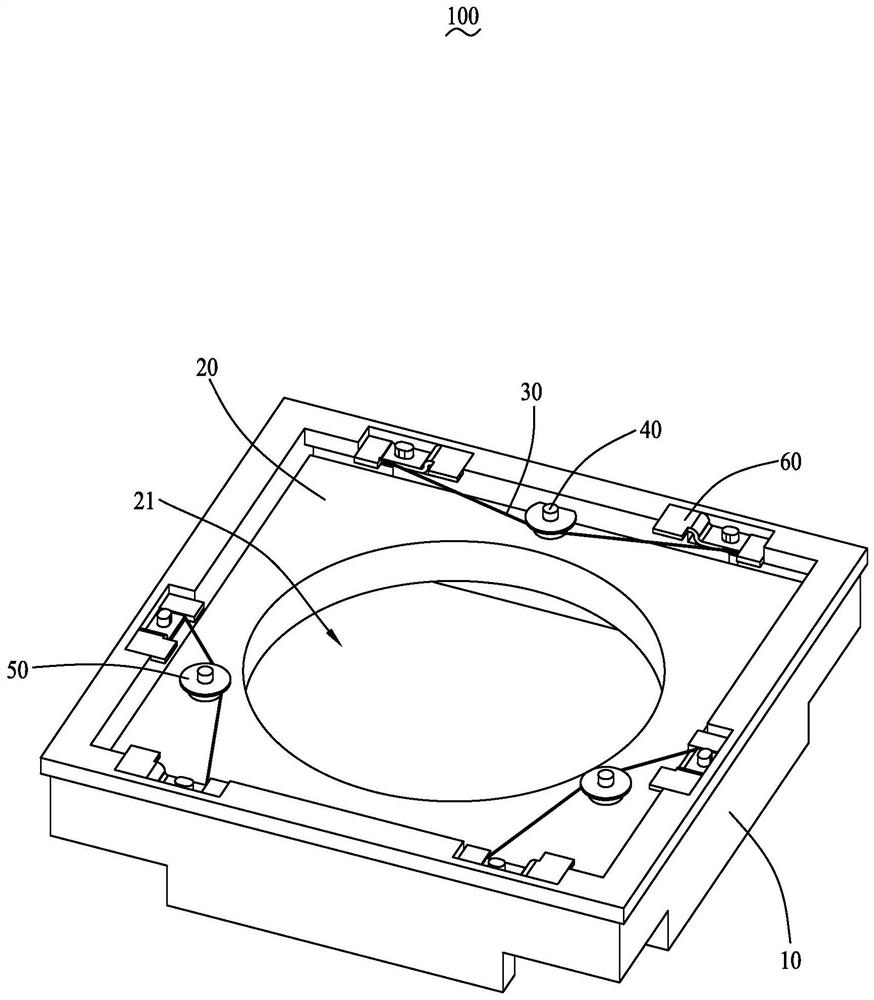

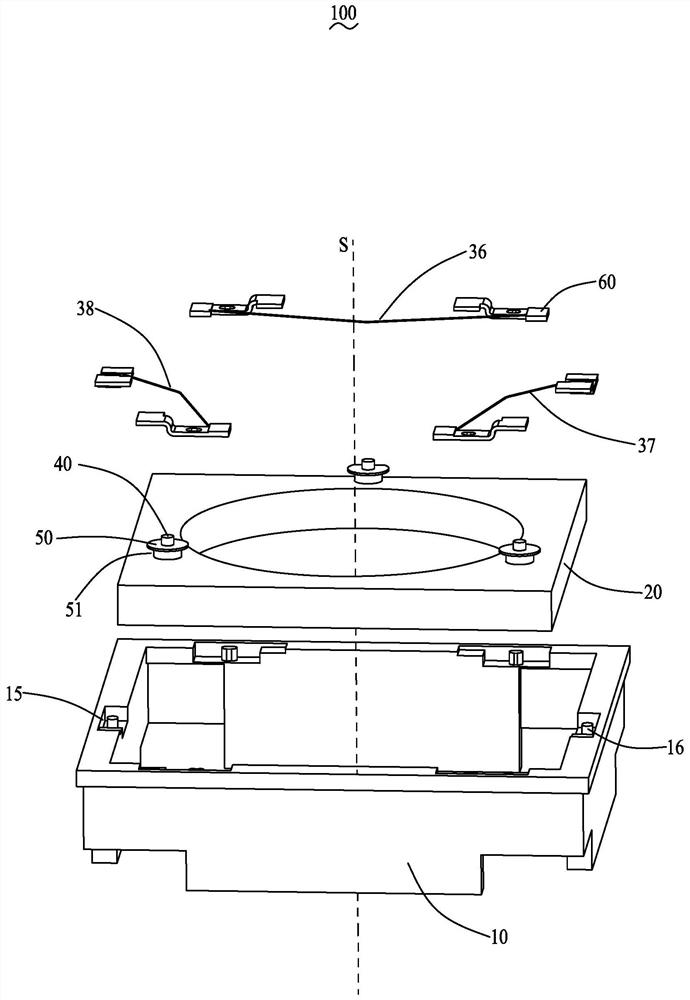

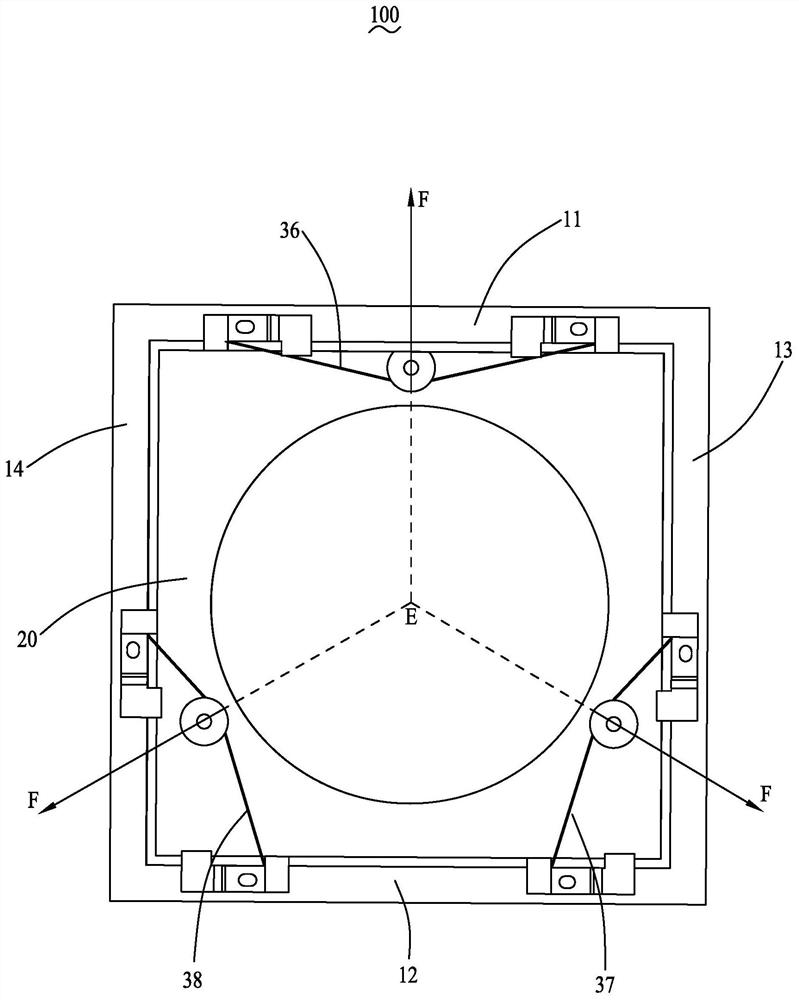

[0031] see Figure 1-4 , Embodiment 1 of the present invention provides an optical anti-shake assembly 100, including a first base 10, a second base 20, and three shape memory alloy wires 30, the first base 10 is ring-shaped, and the second base 20 Spaced on the inside of the first base 10, the second base 20 is provided with mounting holes 21 for lens mounting. Each shape memory alloy wire 30 includes a first fixed end 31 fixed on the first base 10, a first extension section 32 extending from the first fixed end 31 toward the second base 20, and fixed on the second base. The second fixed end 33 of 20, the second extension section 34 extending from the second fixed end 33 toward the direction of the first base 10, and the third fixed end 34 connected with the second extension section 34 and fixed on the first base 10 end 35, the first fixed end 31 and the third fixed end 35 are spaced apart, and the end of the first extension section 32 away from the first fixed end 31 is fix...

Embodiment 2

[0046] see Figure 8 The main difference between the optical anti-shake assembly 200 provided in this embodiment and the optical anti-shake assembly 100 provided in Embodiment 1 is that the arrangement of the three shape memory alloy wires is different, which is specifically reflected in: in this embodiment, the second side plate 201 is provided with only one connection terminal 202, and the fourth side plate 203 is provided with two connection terminals 202, the first fixed end and the third fixed end of the third shape memory alloy wire 204 are fixed to the fourth side plate 203 The two terminals 202.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com