Reading identification method for single-pointer instrument based on shale gas field production

A technology for instrument reading and recognition methods, applied in character and pattern recognition, instruments, computer parts, etc., can solve problems such as low instrument image, inability to accurately identify clarity, and low clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

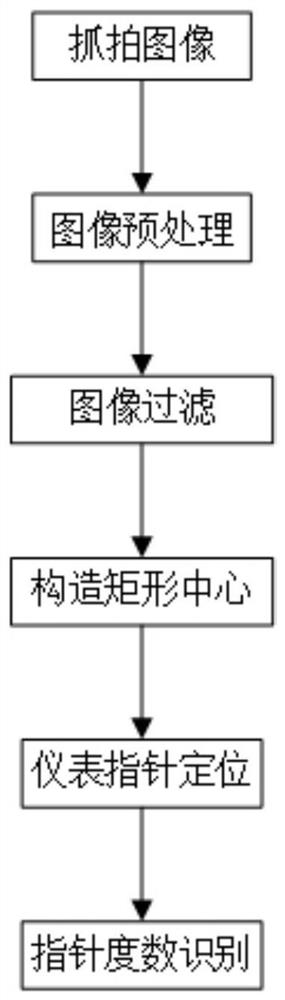

[0067] An identification method based on single-pointer instrument readings in shale gas field production, such as figure 1 , mainly including the following steps in sequence:

[0068] Step 1, capture the image: use the mechanical instrument model trained by deep learning to detect and locate the position of the mechanical instrument in the captured image, intercept the sub-image of the instrument, and perform computer vision analysis of the mechanical instrument;

[0069] Step 2, image preprocessing: perform image preprocessing on the intercepted sub-image of the mechanical instrument, and perform image resampling;

[0070] Step 3, image filtering: transfer the resampled image from RGB space to HSV space, loop through the V channel data of the image space, detect and find the boundary of the speckle under each V value;

[0071] Step 4, constructing the central rectangle: constructing the central rectangle of the sub-image of the mechanical meter, and filtering the border of ...

Embodiment 2

[0082] On the basis of the above-mentioned embodiment 1, the step 3 mainly includes the following steps carried out in sequence:

[0083] Step 3-1: Convert the resampled image from RGB space to HSV space;

[0084] Step 3-2: Loop through the V value of the HSV image space from 80 to 230, perform 150 boundary judgments and search for each image, and find the boundary of the map spot.

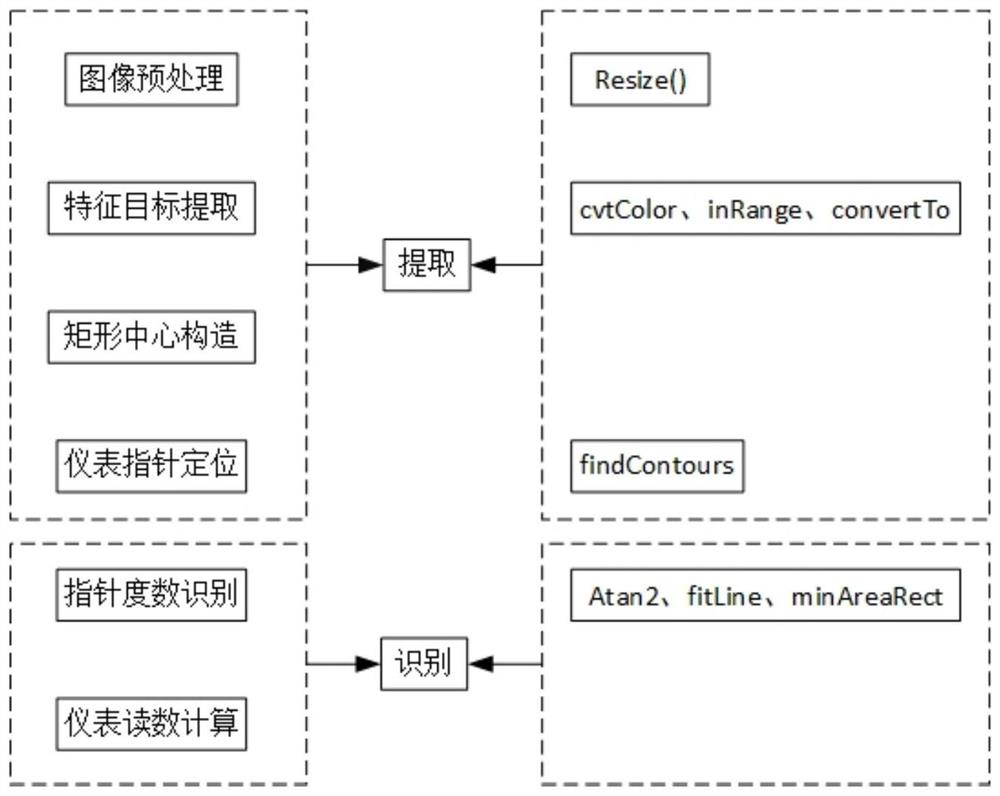

[0085] It should be noted that in different application scenarios, the value range of HSV is different, such as figure 2 , the present invention utilizes the cvSplit function in openCV to select the image type, the value range of H is 0-180, the value range of S is 0-255, the value range of V is 0-255, and when the V value is too large or too small The error range of the patch boundary is too large, so we choose a middle range of V value range to loop through, here we choose the V value range from 80 to 230.

[0086] Working principle: By analyzing the instrument images under different rotation...

Embodiment 3

[0088] On the basis of the above-mentioned embodiment 1 or 2, when loop traversing the V channel data of the image space in the step 3, the influencing factors of the loop termination mainly include the aspect ratio of the minimum circumscribed rectangle of the boundary line, the minimum side of the minimum circumscribed rectangle At least one of the length ratio of the side length ratio of the center rectangle of the construction instrument, the area of the boundary line to the area ratio of the center rectangle of the construction instrument, and the values of the impact factors are all within the predefined threshold, the loop terminates, otherwise continue to loop through the search Blob border.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com