A process parameter optimization method for multi-process industrial production process

A technology for process parameter optimization and industrial production, applied in the field of tobacco silk making, can solve the problems affecting the quality of finished cigarettes and the high rate of broken silk, and achieve the effects of reducing the number of input variables, improving efficiency and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

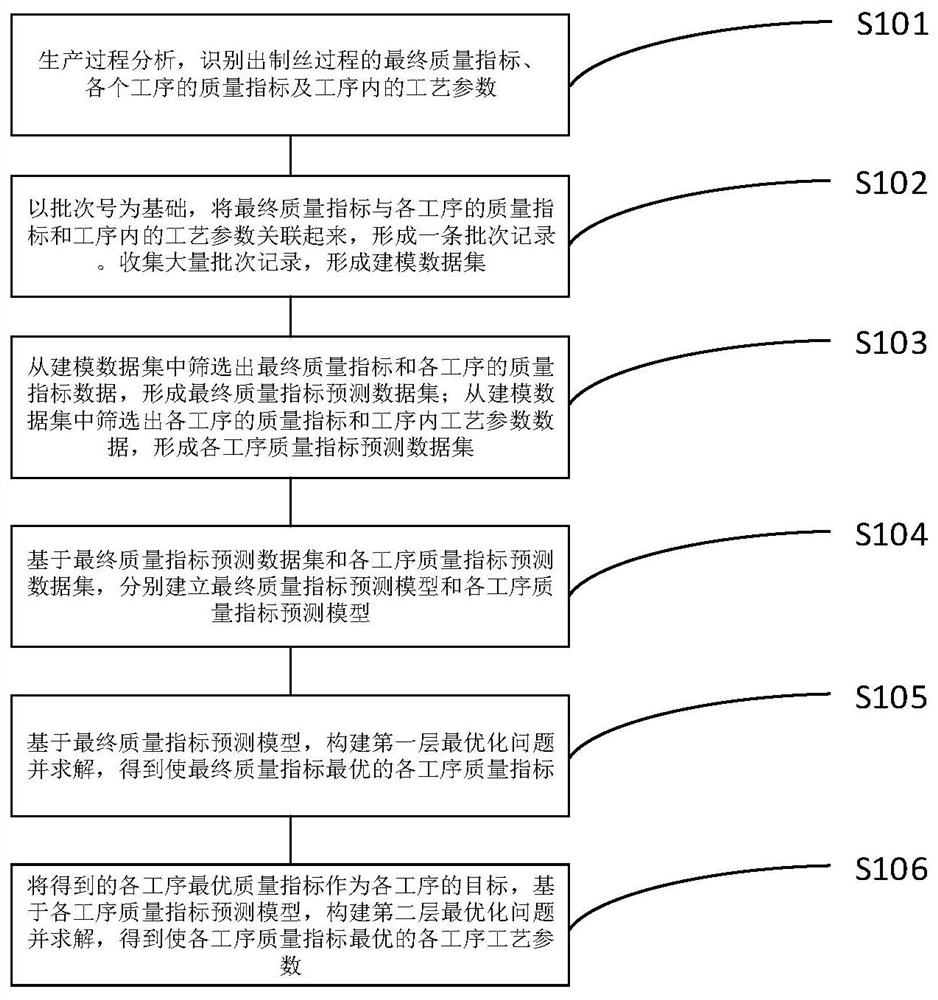

[0034] Embodiment one: a kind of process parameter optimization method for multi-process industrial production process, comprises the following steps:

[0035] Step S101: analyzing the production process, identifying the final quality index of the industrial production process, the quality index of each process and the process parameters in the process.

[0036] Step S102: Based on the batch number, associate the final quality index with the quality index of each process and the process parameters in the process to form a batch record, and collect multiple batch records to form a modeling data set.

[0037] Step S103: Screen out the final quality index and quality index data of each process from the modeling data set to form a final quality index prediction data set; screen out the quality index of each process and process parameter data in each process from the modeling data set to form each Process quality index prediction dataset.

[0038] Step S104: Based on the final qua...

Embodiment 2

[0050] Embodiment 2, a process parameter optimization method for a multi-process industrial production process, the multi-process industrial production process is a tobacco shred process, such as figure 1 shown, including the following steps:

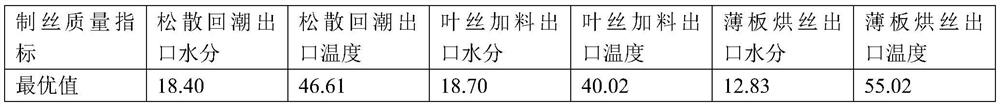

[0051] Step S101: Analyzing the production process, identifying the final quality index of the silk-making process, the quality index of each process and the process parameters in the process; the final quality index is the whole silk rate, and the process includes loosening and regaining moisture, adding shredded leaves and drying the thin plate, The quality indicators of the loosening and regaining process include outlet moisture content and outlet temperature, and the process parameters include inlet moisture content, inlet material flow rate, water flow rate and hot air temperature; the quality indicators of the shredded leaf feeding process include outlet moisture content and outlet temperature, and process parameters include inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com