Universal module bottom shell structure with multiple intervals and multiple installation modes

An installation method and shell structure technology, which is applied in the direction of identification devices, casings/cabinets/drawer parts, electrical equipment casings/cabinets/drawers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

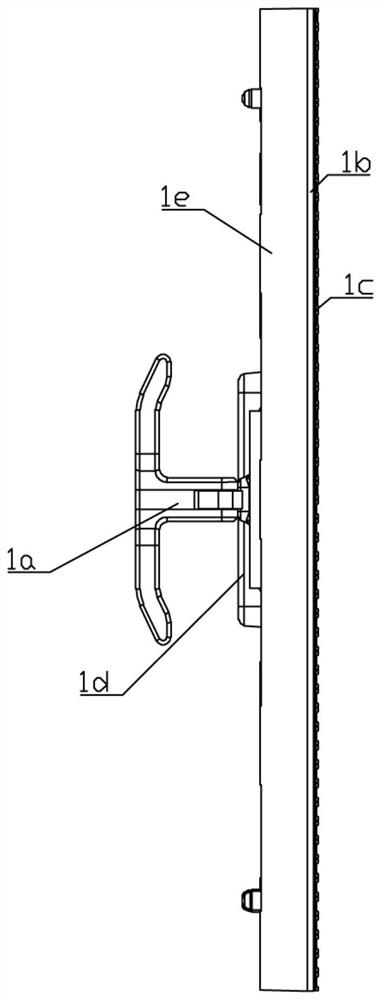

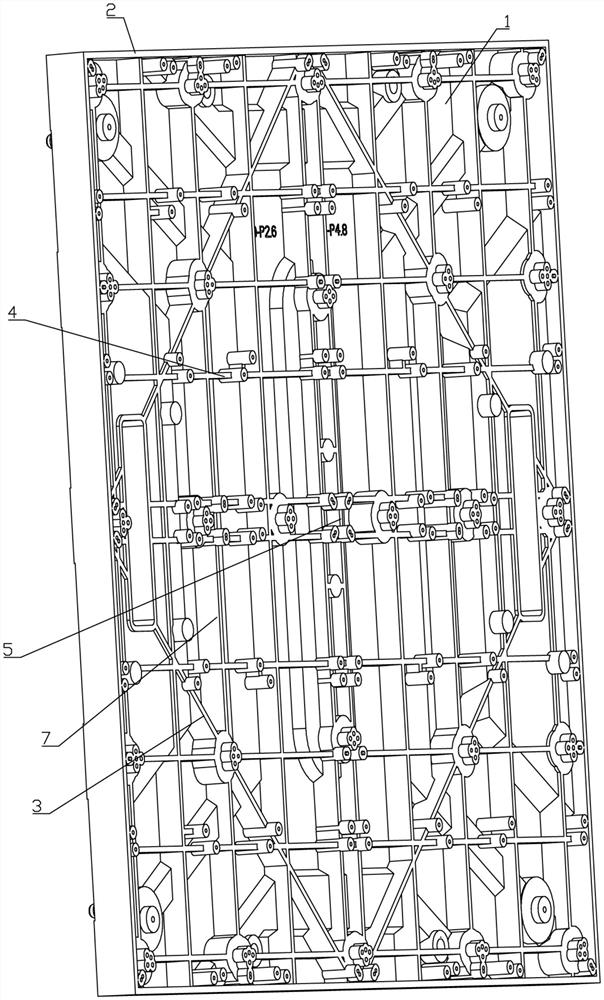

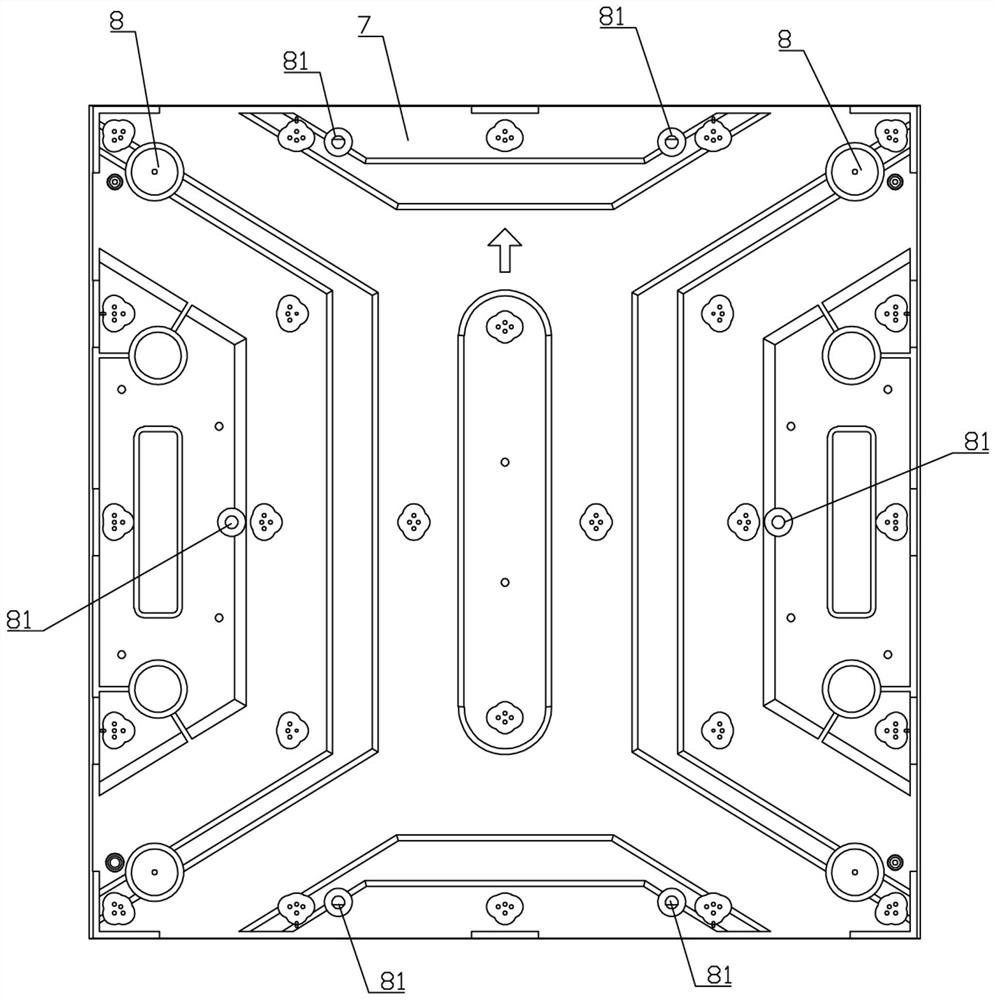

[0031] like Figure 2 to Figure 8 As shown, a modular bottom shell structure of the present invention with multiple spacings and multiple installation methods includes a bottom shell body 1 and a square frame 2, the bottom shell body 1 is provided with a square structure support frame 3, and the support frame 3 The four corners of the support frame 3 are provided with two symmetrical first mounting posts 31, the first mounting posts 31 are provided with two first mounting post holes 32, and the positions of the four corners of the support frame 3 are provided with first mounting seats 33 , the first mounting seat 33 is provided with four first mounting seat holes 34, the four sides of the support frame 3 are provided with two second mounting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com