A crimping device for cables and wiring lugs

A crimping device and cable technology, which is applied in the direction of connection, connection, line/collector parts, etc. by deformation, which can solve the problems of affecting the work process and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

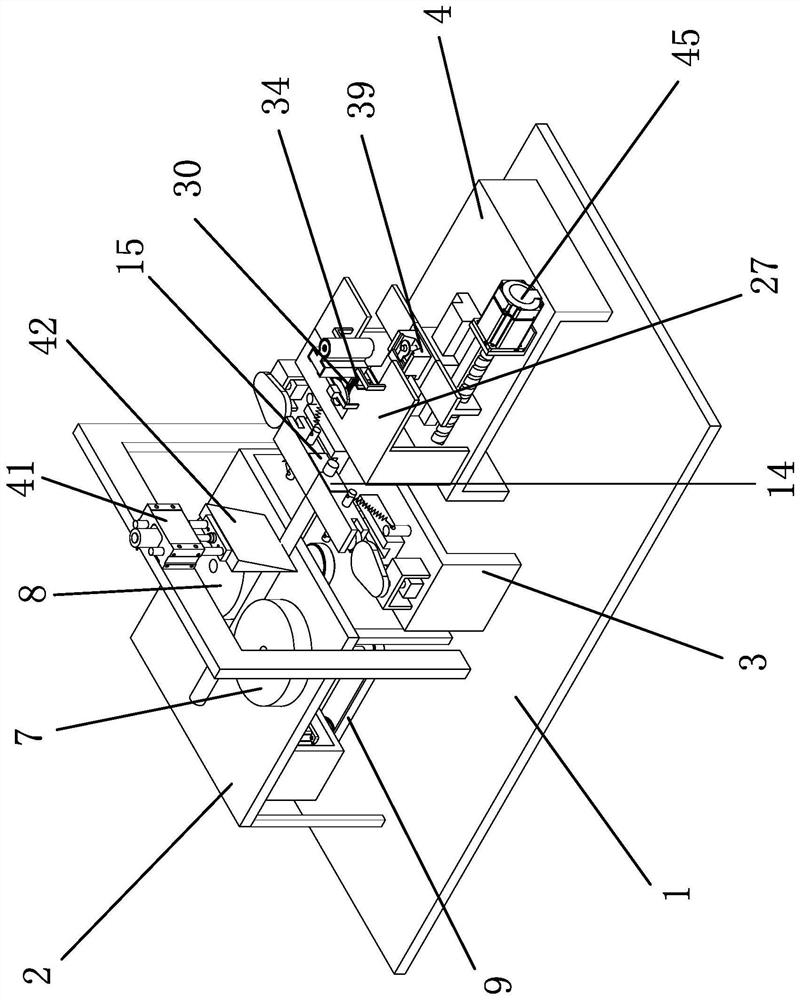

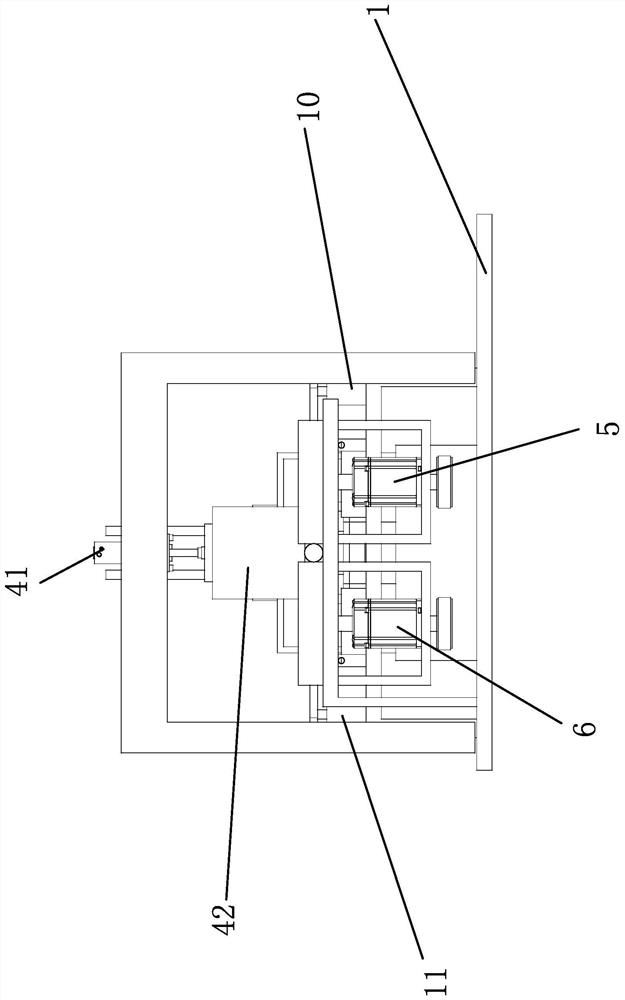

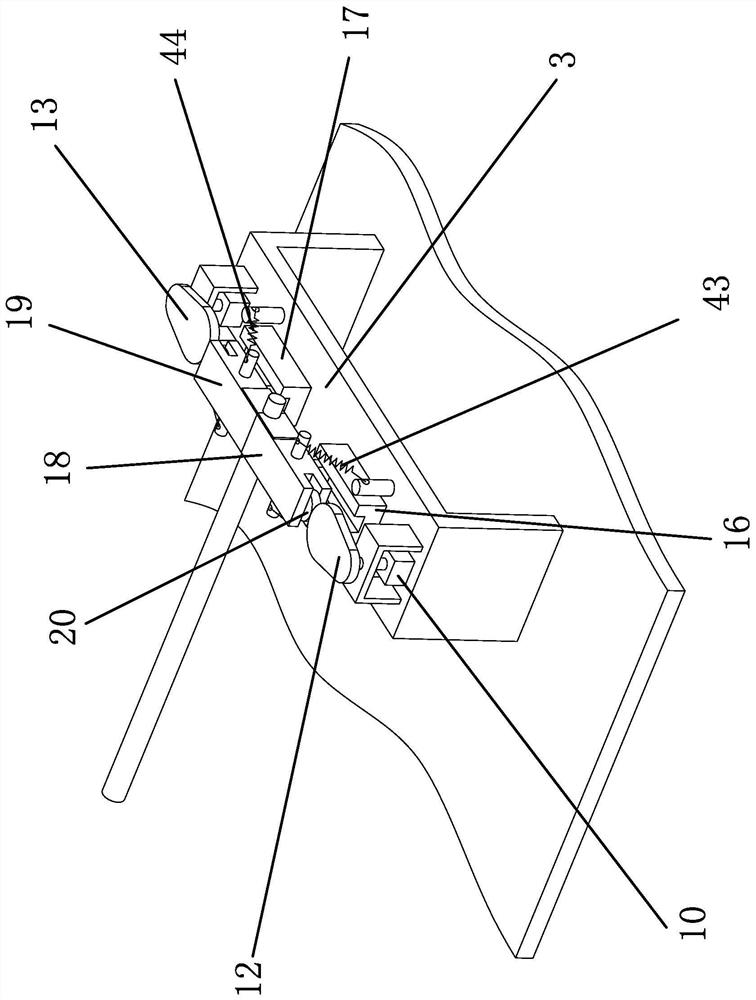

[0029] Such as figure 1 and figure 2 As shown, a crimping device for cables and wiring lugs, including base plate 1, workbench 1, workbench 2, workbench 3 and workbench 3 4, workbench 1 2, workbench 2 3 and workbench 3 4 They are all fixed on the bottom plate 1, and the conveying mechanism for cable transmission is set on the workbench 12. The conveying mechanism includes motor 15, motor 26, traction wheel 17, traction wheel 28; There is a cutting mechanism for breaking away from the cable shell. The cutting mechanism includes motor three 10, motor four 11, cam one 12, cam two 13, blade one 14 and blade two 15; The delivery mechanism for delivery includes a motor five 21, a storage box 24, a baffle plate 25, a baffle pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com