Anti-solidification mechanical stirring device for commercial concrete

A technology of commercial concrete and mechanical mixing, applied in the field of concrete, can solve the problems of cement concrete solidification, low work efficiency, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

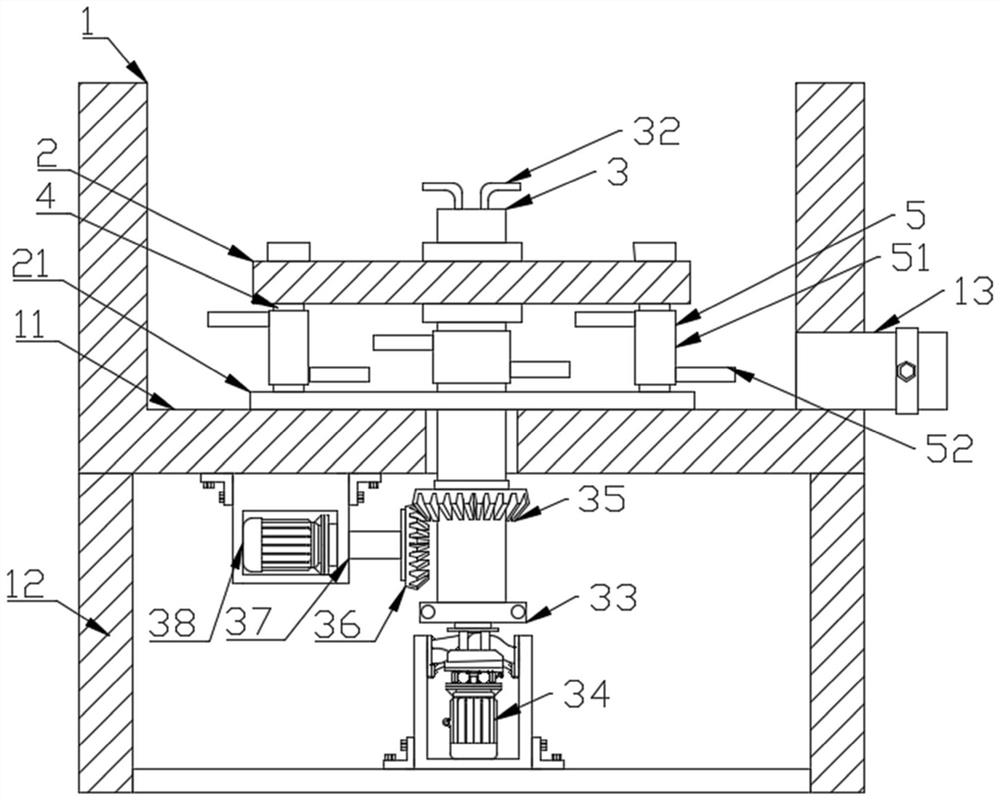

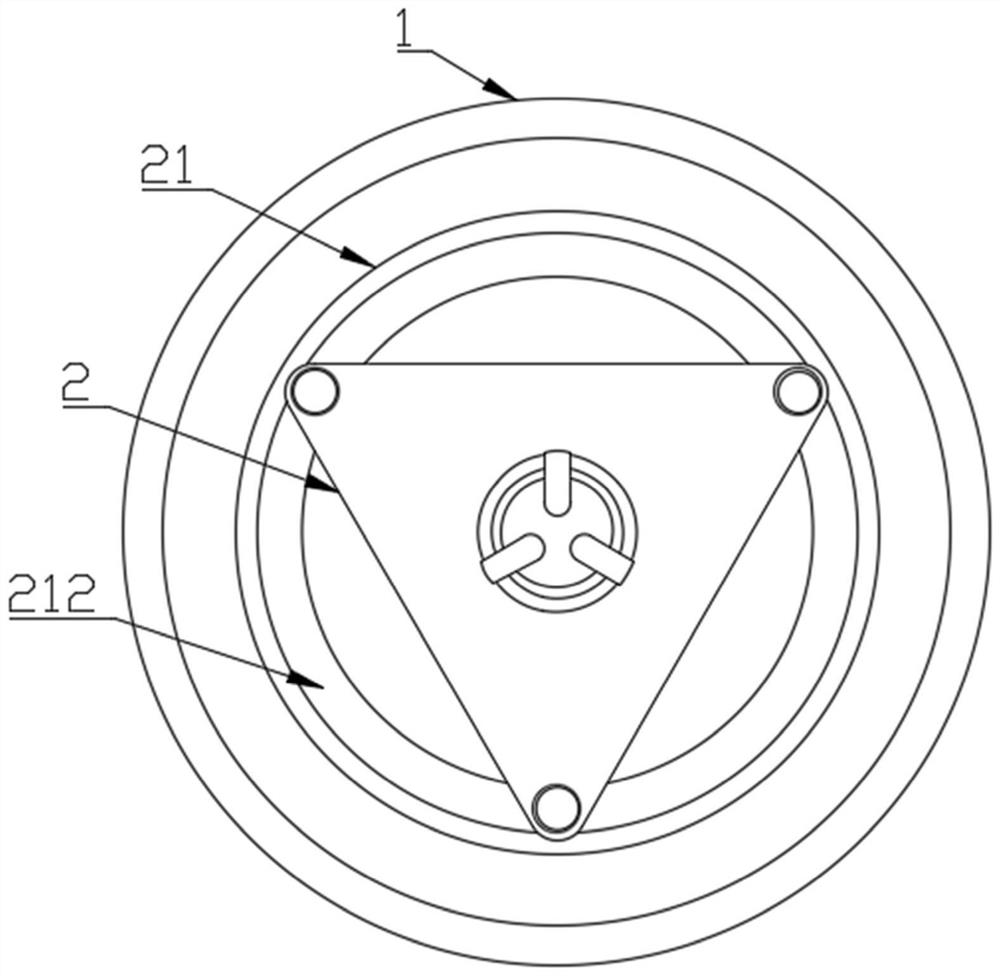

[0026] Embodiment 1, with reference to attached Figure 1-Figure 4 , a commercial concrete anti-freezing mechanical stirring device provided by the present invention includes a device body 1, a fixed plate 2, a stirring main rod 3, a stirring auxiliary rod 4 and an impeller 5;

[0027] Further, the limit plate 21 is welded inside the equipment body 1. The equipment body 1 includes a stirring area 11, a bracket 12 and a discharge valve 13. Specifically, the lower end of the stirring area 11 is welded with the bracket 12, and the right end of the stirring area 11 is provided with a discharge valve 13. , through the welding bracket 12 at the lower end of the stirring area 11, it plays a supporting role, and the effect that the equipment body will not move when stirring is achieved. The right end of the stirring area 11 is provided with a discharge valve 13, which plays the role of discharging and achieves the effect of stirring well. The effect of cement concrete discharge;

[0...

Embodiment 2

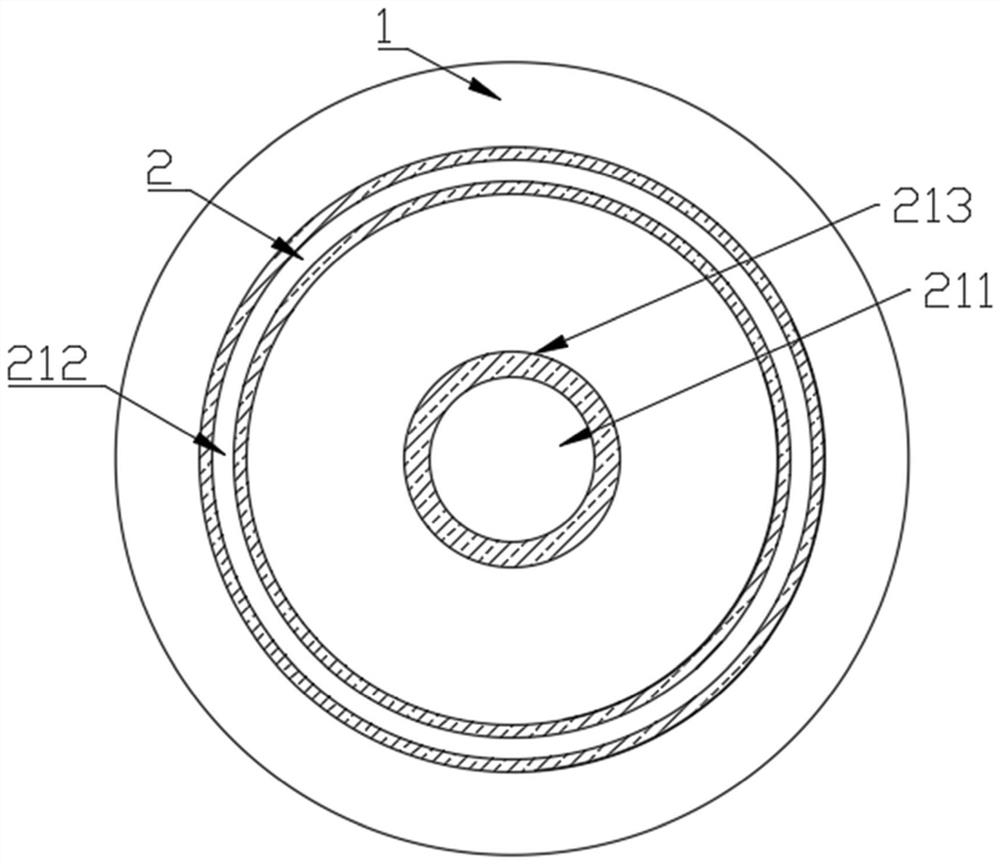

[0032] Embodiment 2, with reference to attached Figure 5 , a commercial concrete anti-solidification mechanical stirring device provided by the present invention, comprising an impeller 5;

[0033] Further, the impeller 5 is sleeved on the outer wall of the stirring main rod 3 and the stirring sub-rod 4, and the impeller 5 also includes a helical blade 53. Specifically, the helical blade 53 is welded to both ends of the sleeve body 51. Since the inner wall of the sleeve body 51 is sleeved on the stirring The outer wall of the main rod 3 and the stirring sub-rod 4, the helical blade 53 is welded to the two ends of the sleeve body 51, and the helical blade 53 is set in a shape of high left and right low, which plays a role in increasing the mixing efficiency, so as to make the mixing of cement concrete more efficient. Even, the effect of increasing work efficiency;

[0034] The use process of the present invention is as follows: those skilled in the art weld the support 12 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com