Easy-to-demold injection mold with buffering effect

An injection mold and buffering technology, applied in the field of easy-release injection molds, can solve problems such as damage to injection products, and achieve the effect of avoiding damage and facilitating separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

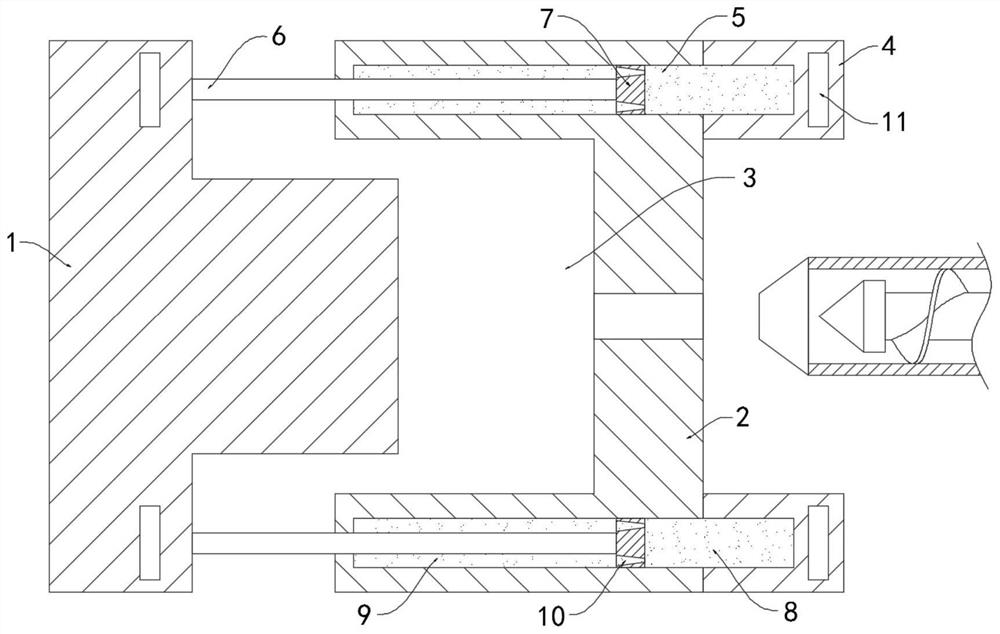

[0022] Such as Figure 1-2 As shown, a kind of easy-release injection mold with cushioning effect includes a movable mold 1 and a fixed mold 2, an injection cavity 3 is formed between the movable mold 1 and the fixed mold 2, and the plastic solution is injected into the injection cavity through the injection hole during injection molding 3, the above is the prior art, and will not be repeated here.

[0023] The upper and lower ends of the outer wall of the fixed mold 2 are fixedly connected with a fixed block 4, and the fixed mold 2 is provided with a buffer cavity 5 corresponding to the fixed block 4. The buffer cavity 5 extends to the fixed block 4 and is set. Filled with electrorheological fluid, the viscosity of the electrorheological fluid will change with the strength of the electric field it is in. When the electric field strength becomes larger, the viscosity increases, and when the electric field strength becomes smaller, the viscosity decreases.

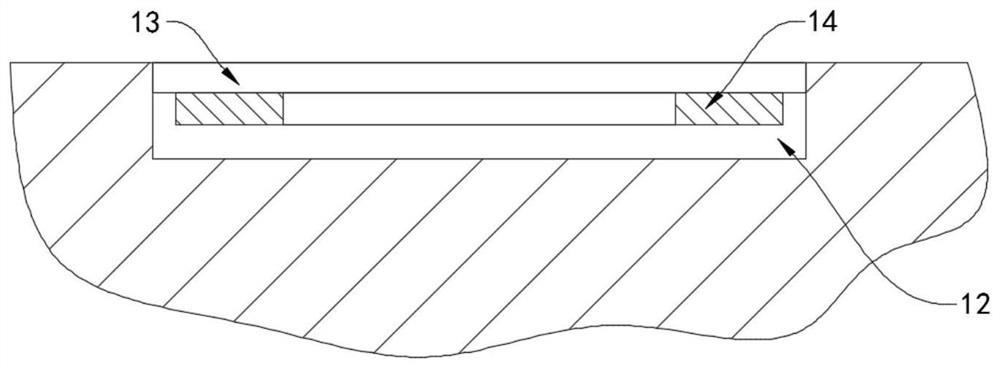

[0024] The upper a...

Embodiment 2

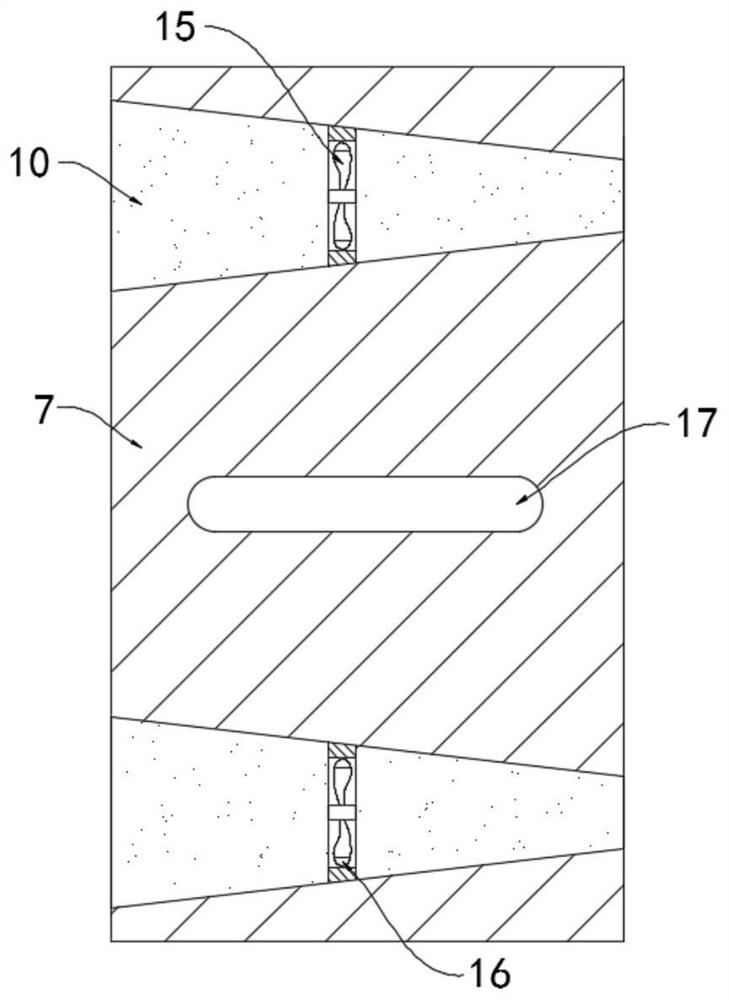

[0035] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that each communication hole 10 is fixedly connected with a rotating fan 15 perpendicular to the axis of the communication hole 10, and the end of each blade of the rotating fan 15 is fixed. A magnetic block 16 is connected, and a magnetic plate 17 is fixedly embedded in the sliding block 7 .

[0036]In this embodiment, after the injection molded product is solidified, while the movable mold 1 is moving away from the fixed mold 3, the electrorheological fluid in the buffer cavity 5 will flow, driving the rotating fan 15 to rotate, and the rotating fan 15 on the blades The magnetic block 16 cuts the magnetic induction line of the magnetic plate 17 to generate a current, so that the electrode plate 11, the piezoelectric plate 14 and the vibrating plate 13 conduct current, and no additional power supply is needed, which saves energy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com