Sterilization equipment for beverage production

A sterilizing equipment and beverage technology, applied in the direction of milk preservation, other dairy products, dairy products, etc., can solve the problems of beverage turbidity, affect the taste, reduce the quality, etc., achieve pure beverages, better taste, and avoid beverage turbidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

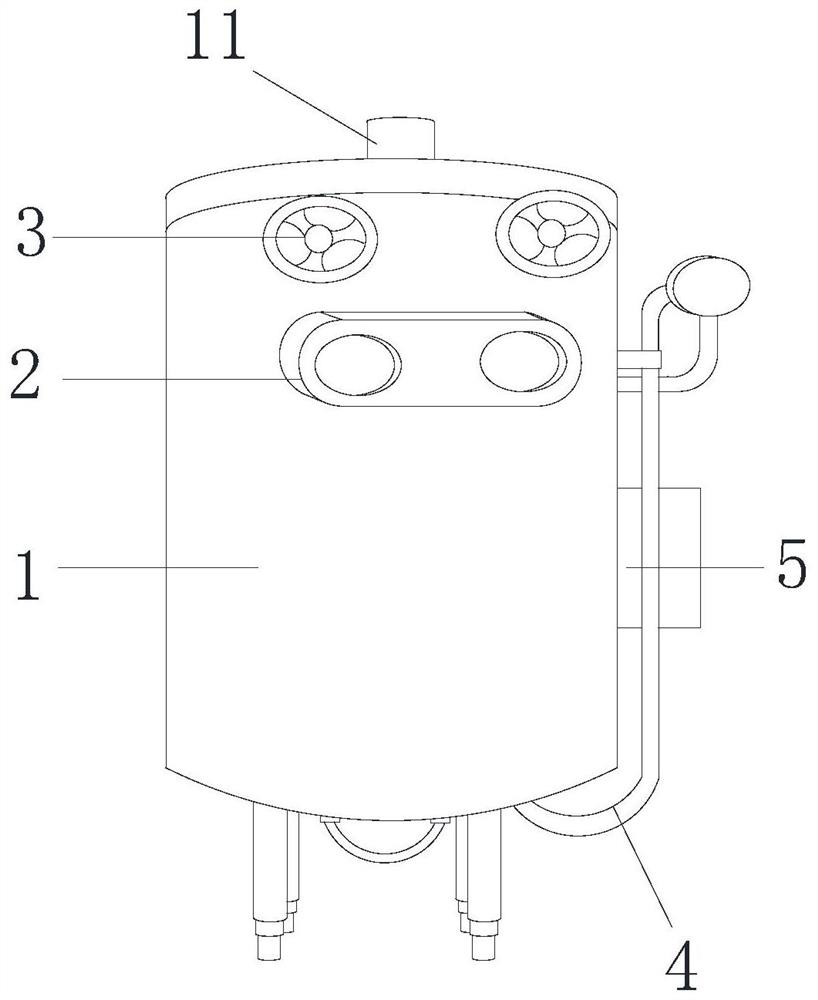

[0025] see Figure 1-Figure 4 , a sterilizing device for producing beverages, the invention provides a sterilizing device for producing beverages, the structure of which includes a sterilizing tank 1, a sterilizing instrument panel 2, a sterilizing control valve 3, a connecting pipe 4, and a control electric box 5. The sterilization instrument panel 2 is arranged on the front surface of the sterilization tank 1, the sterilization control valve 3 is arranged on the front side surface of the sterilization tank 1, and is arranged on the top of the sterilization instrument panel 2, and the connection is through The bottom of the tube 4 is connected to the interior of the sterilization tank 1, and the control electrical box 5 is arranged on the rear side of the sterilization tank 1, and the characteristics are as follows:

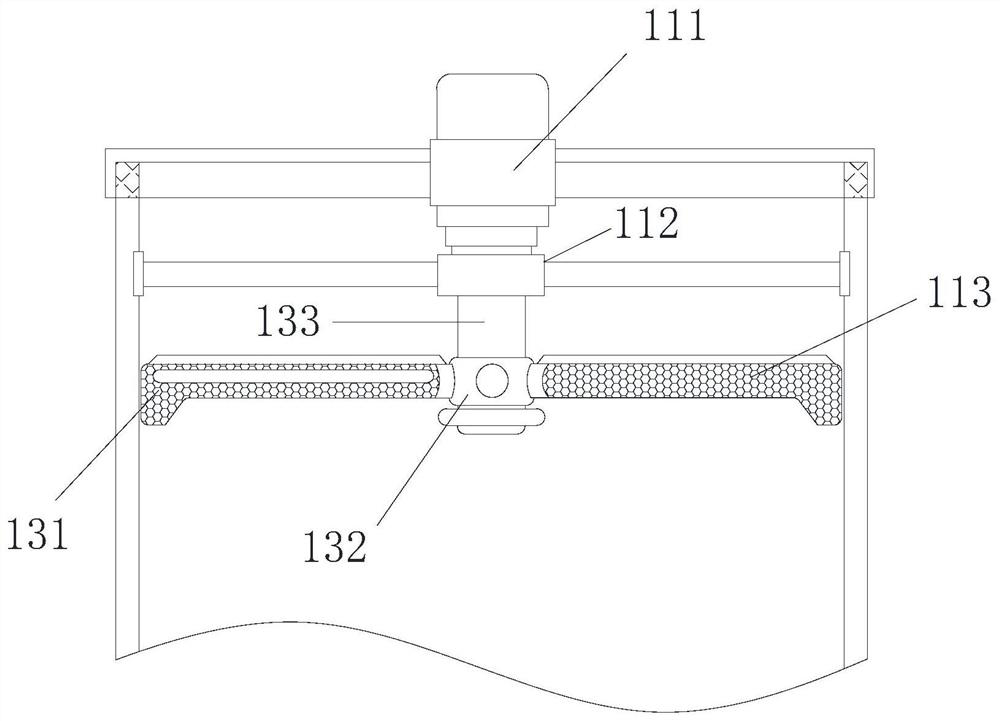

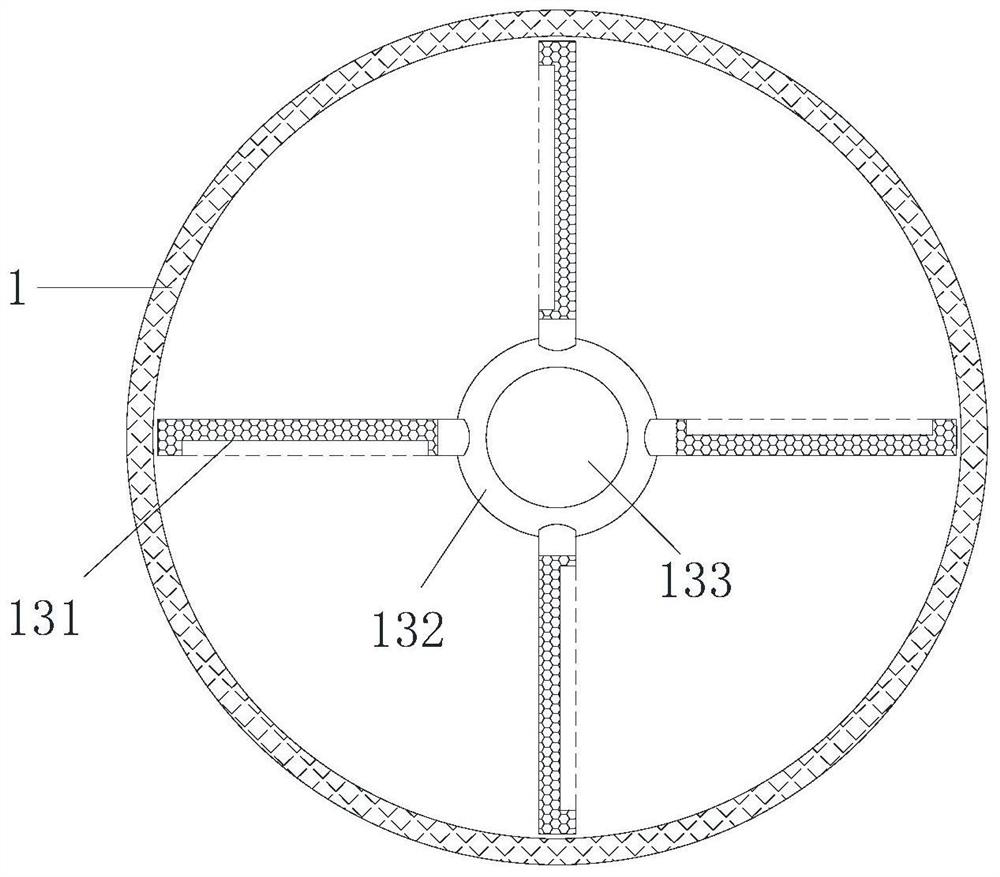

[0026] The sterilizing tank 1 is provided with a coagulation film removal device 11, and the coagulation film removal device 11 is arranged at the inner upper e...

Embodiment 2

[0035] see Figure 5 , a sterilizing device for producing beverages, the present invention provides a sterilizing device for producing beverages, the structure of which includes a collecting and sealing assembly 1314, and the collecting and sealing assembly 1314 is arranged at one end inside the condensation film inlet 1313.

[0036] The collection and sealing assembly 1314 is composed of a fixed long pin 4a, a sealing plate 4b, and a sealing spring 4c. The left and right ends of the fixed long pin 4a are fixed on the inner two ends of the condensation film storage chamber 1311, and the top of the sealing plate 4b There is a collar nested with the fixed long pin 4a, and it is movably connected. One end of the sealing spring 4c is fixedly connected to the inner rear surface of the condensed film storage chamber 1311, and the other end is connected to the bottom of the sealing plate 4b to form the bottom of the sealing plate 4b. The state of leaning outward.

[0037] On the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com