Industrial environment-friendly dust removal equipment convenient for dust removal

A dust removal equipment and industrial technology, applied in the field of industrial environmental protection dust removal equipment, can solve the problems of inconvenient use, physical injury, inability to clean and discharge dust, etc., and achieve the effects of increasing cleaning effect, high reliability and novel design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

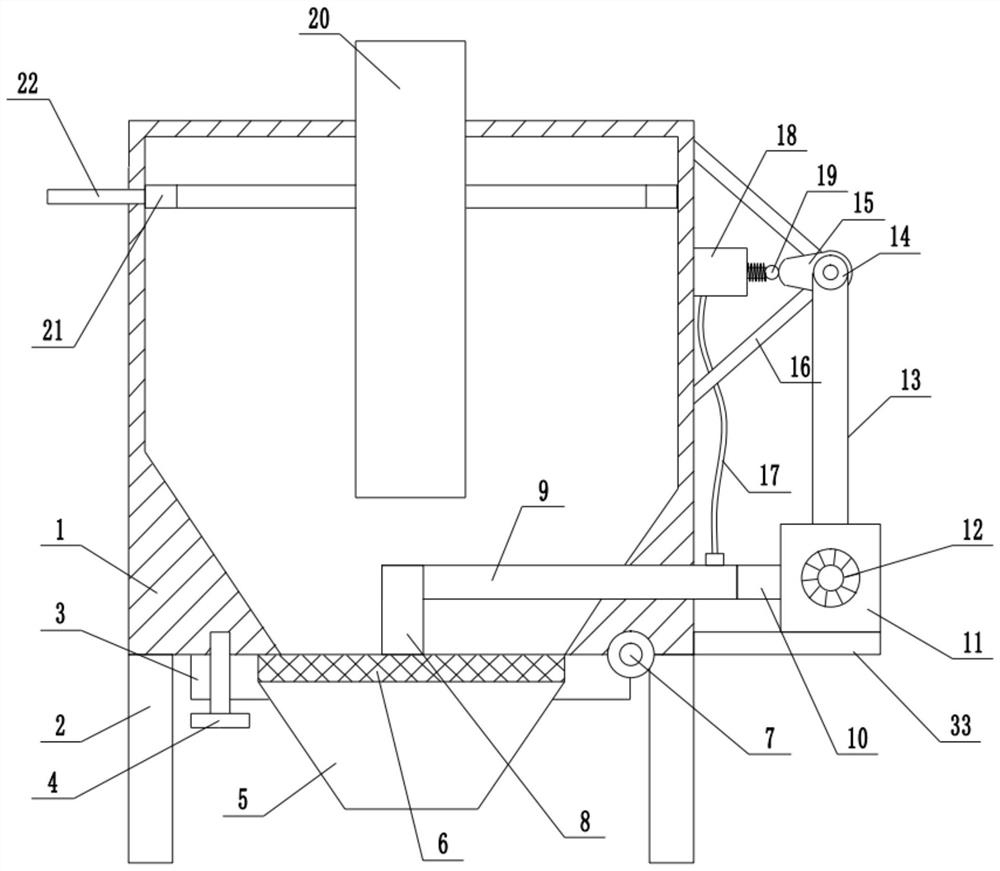

[0030] refer to Figure 1~5 , in an embodiment of the present invention, an industrial environment-friendly dedusting device for cleaning dust, including a dust removal box 1, and support legs 2 are installed on both sides of the lower end of the dust removal box 1, to ensure the support and fixation of the entire device, the dust removal box 1 An air injection ring 21 is installed on the upper end of the inner wall, and the air injection ring 21 is internally connected with an air intake pipe 22. The inner wall of the air injection ring 21 is provided with a number of obliquely arranged air injection holes 31, and the air injection holes 312 are obliquely arranged on the inner wall of the air injection ring 21, so that the air injection ring 21 The blown industrial flue gas is sprayed tangentially along the inner wall of the dust removal box 1, thereby increasing the effect of cyclone dust removal. An exhaust pipe 20 is installed vertically on the top of the dust removal box 1...

Embodiment 2

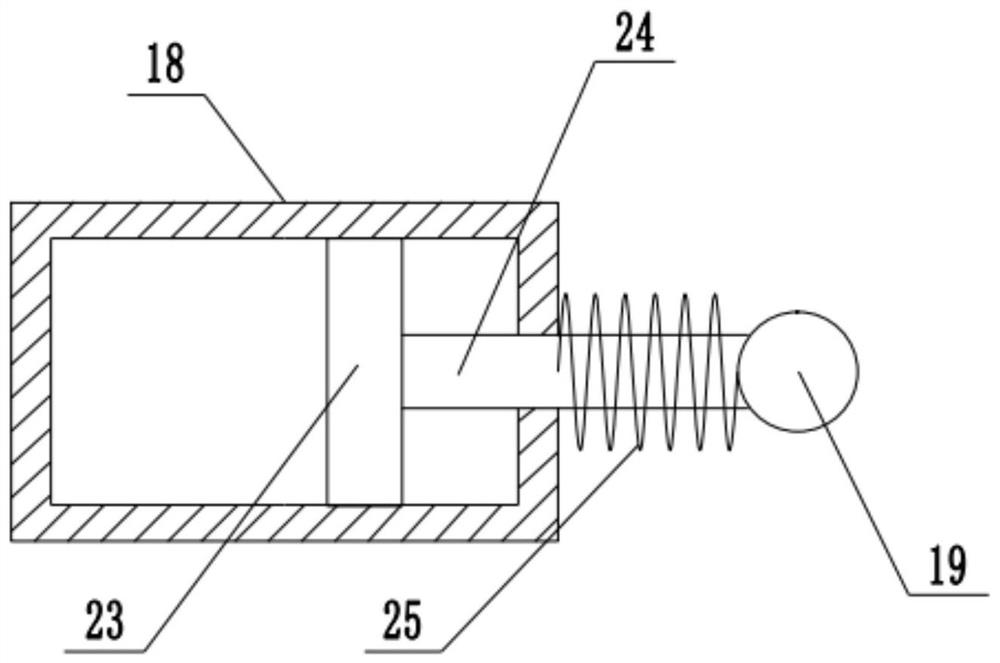

[0032] In another embodiment of the present invention, the difference between this embodiment and the above-mentioned embodiment is that the rear end of the cam 15 is rotatably connected to the limit frame 16, and the limit frame 16 is fixed on the outer wall of the dust removal box 1, and then the The limiting function of the driven pulley 14 and the cam 15 during rotation.

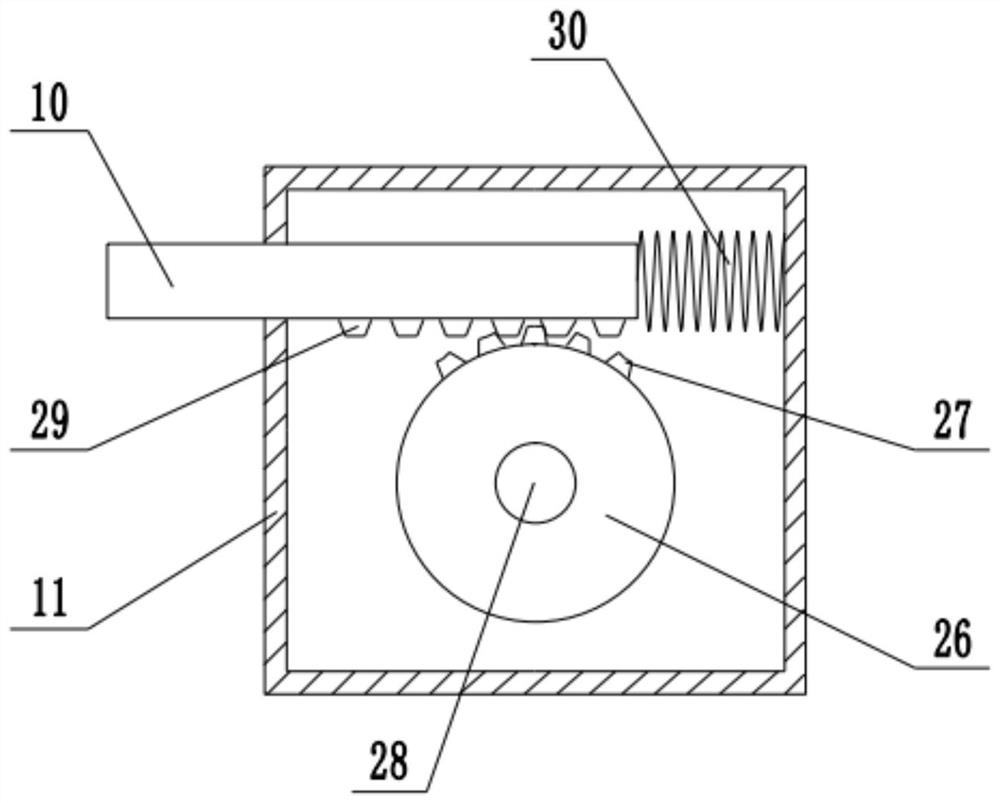

[0033]In the present invention, when working, the intake pipe 22 introduces industrial smoke, and the industrial smoke is sprayed out from the air injection hole 31. Under the setting effect of the outlet tube 20, the cyclone dust removal is realized, and the dust falls into the upper end of the filter screen 6 along the bottom end of the outlet tube 20 At the same time, the drive motor 12 is started, and the drive motor 12 drives the drive wheel 26 to rotate, so that the ring teeth 27 and the rack 29 are periodically engaged, and under the action of the moving spring 30, the swing scraper 8 is scraped al...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap