Argon filling tool and method for argon arc welding butt joint of large-diameter pipelines

A large-diameter pipe and argon-filled technology, which is applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of increasing welding difficulty, argon filling volume, and slow welding speed, so as to facilitate argon flow and easy cleaning , the effect of reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment, and its content is explanation of the present invention rather than limitation:

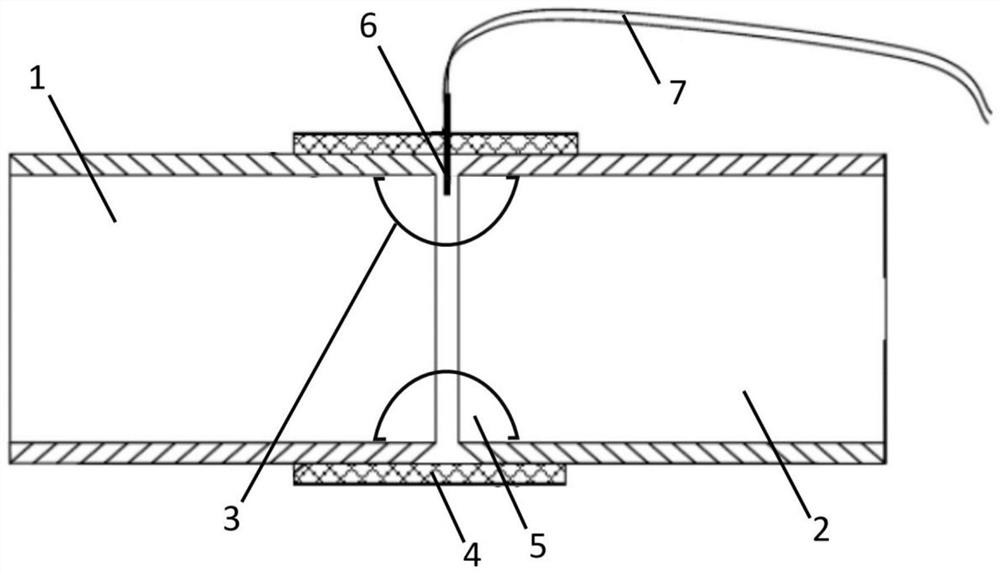

[0031] like figure 1 , the argon-filled frock for large-diameter pipeline argon arc welding butt joint of the present invention includes an arched shell 3, a flexible blocking plate 4 and an air filling nozzle 6; the two arched feet of the arched shell 3 are respectively connected to the two The inner walls of the two pipes are connected, and the vault of the arched shell 3 faces the inside of the two pipes to be welded; the flexible blocking plate 4 is wound on the outer walls of the two pipes to be welded, and the arched shell 3 and the flexible blocking plate 4 form a The closed air chamber 5 surrounded by the welding port; the flexible blocking plate 4 is provided with an inflation port and an exhaust port, and the inflation nozzle 6 is inserted in the infla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com