A large particle oil physical pressing device

A kind of oil physics and large particle technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of affecting the oil yield, large oil residue, and the oil extraction of Chinese torreya is not thorough enough to achieve the effect of improving the oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

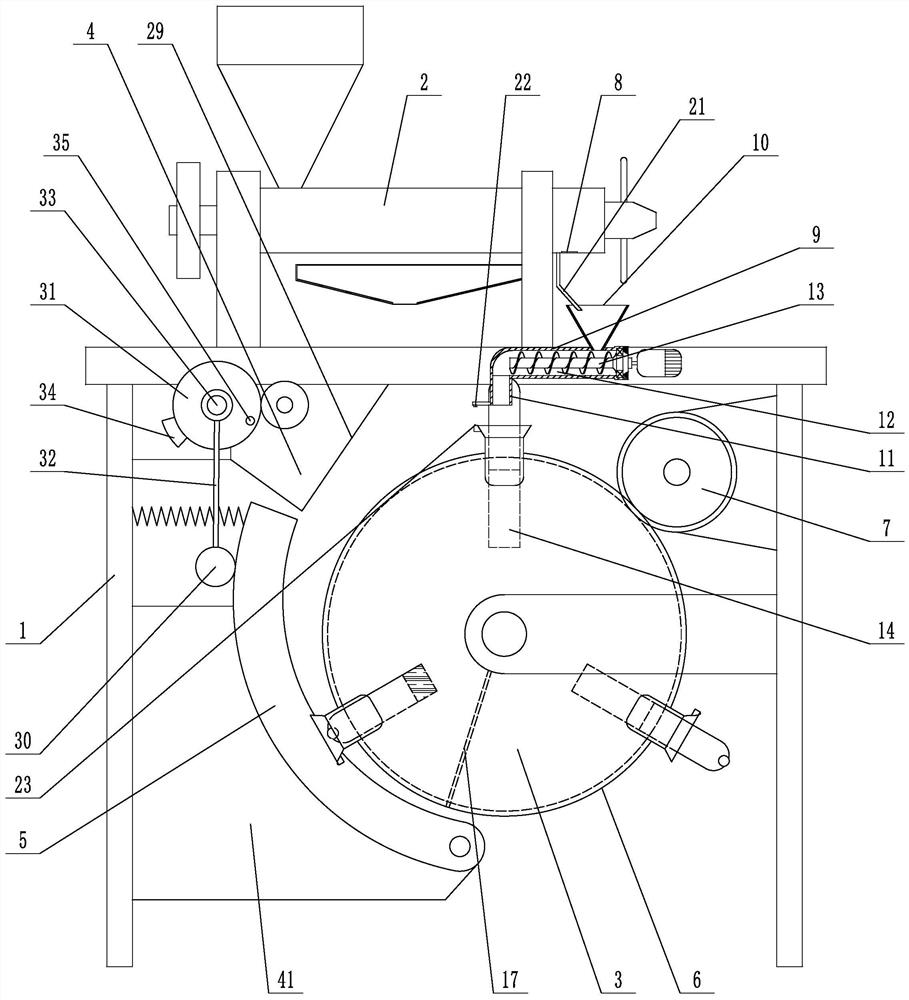

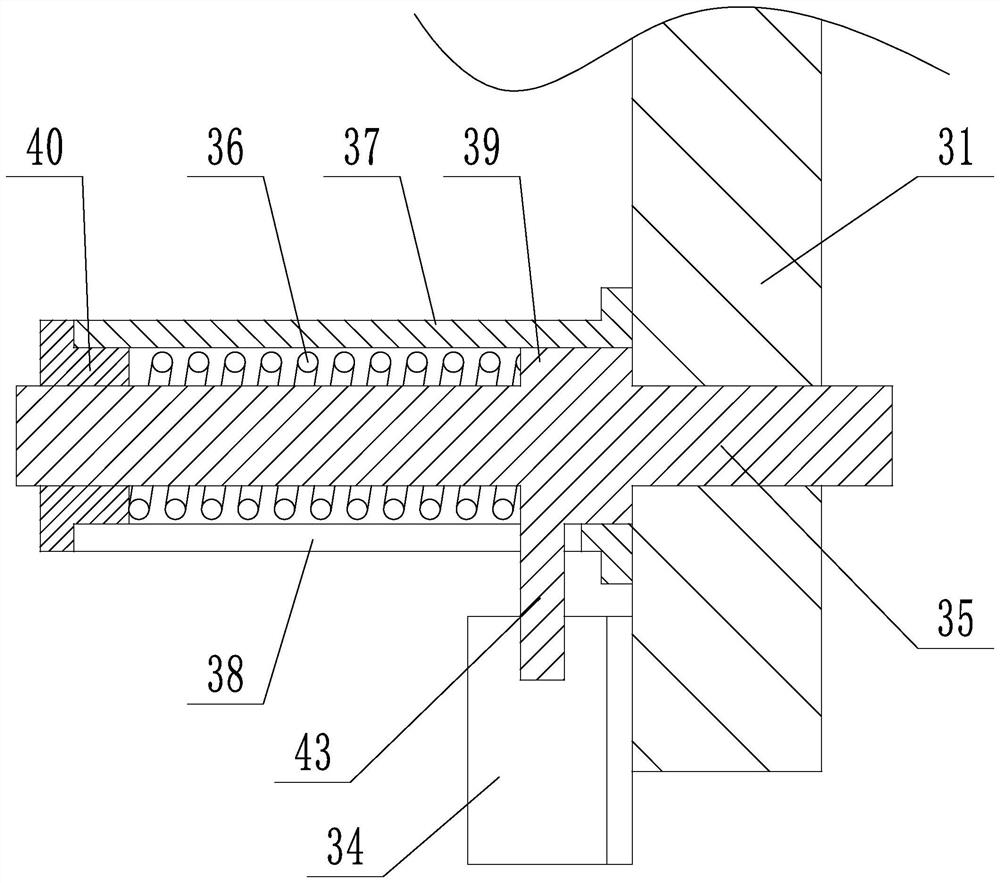

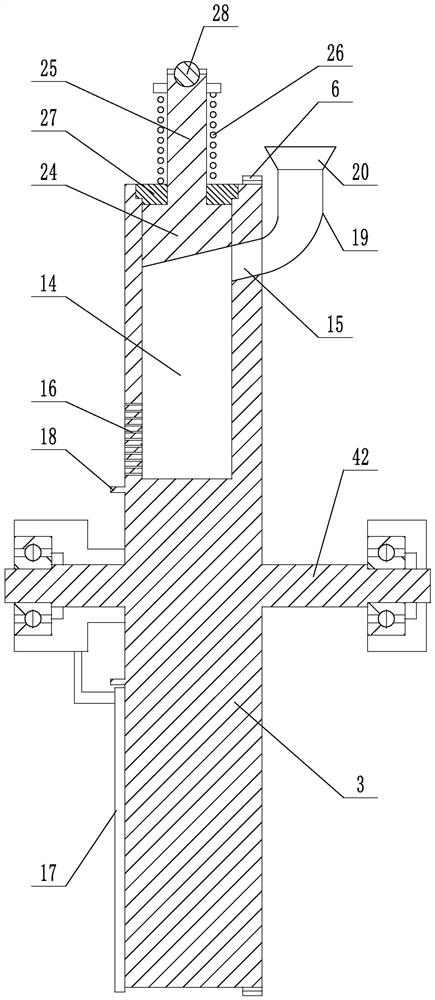

[0021] Embodiment: a kind of large particle oil plant physical pressing device (see attached figure 1 , attached figure 2 , attached image 3 ), comprising a frame 1, an oil press 2 installed on the frame, and the oil press adopts an existing screw oil press. The secondary oil extraction mechanism is installed on the frame, and the secondary oil extraction mechanism includes a turntable 3, a fixed guide block 4, a shaking guide block 5, a ring gear 6 is arranged on the edge of the turntable, and a transmission gear 7 driven by a motor is installed on the frame. The transmission gear is meshed with the ring gear for transmission. The oil press is provided with a slag outlet 8, and a screw feeder 9 is installed between the slag outlet and the turntable. A feeding channel 12 is arranged inside, and a screw rod 13 is installed in the feeding channel, and one end of the screw rod is connected to the motor output shaft. The receiving hopper is installed at one end of the feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com