Torreya grandis oil pressing device

An oil pressing device and the technology of Torreya, applied in the field of oil pressing equipment, can solve the problems of reducing oil yield and incomplete oil pressing of Torreya, and achieve the effect of improving oil yield and ensuring reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

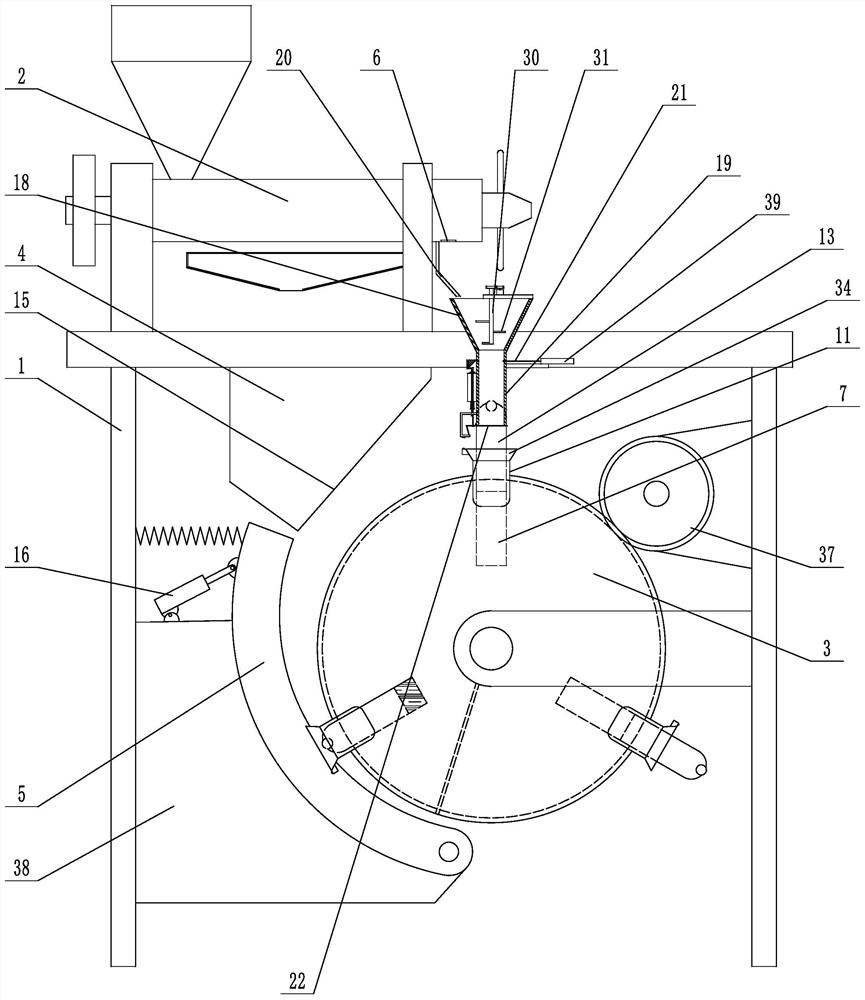

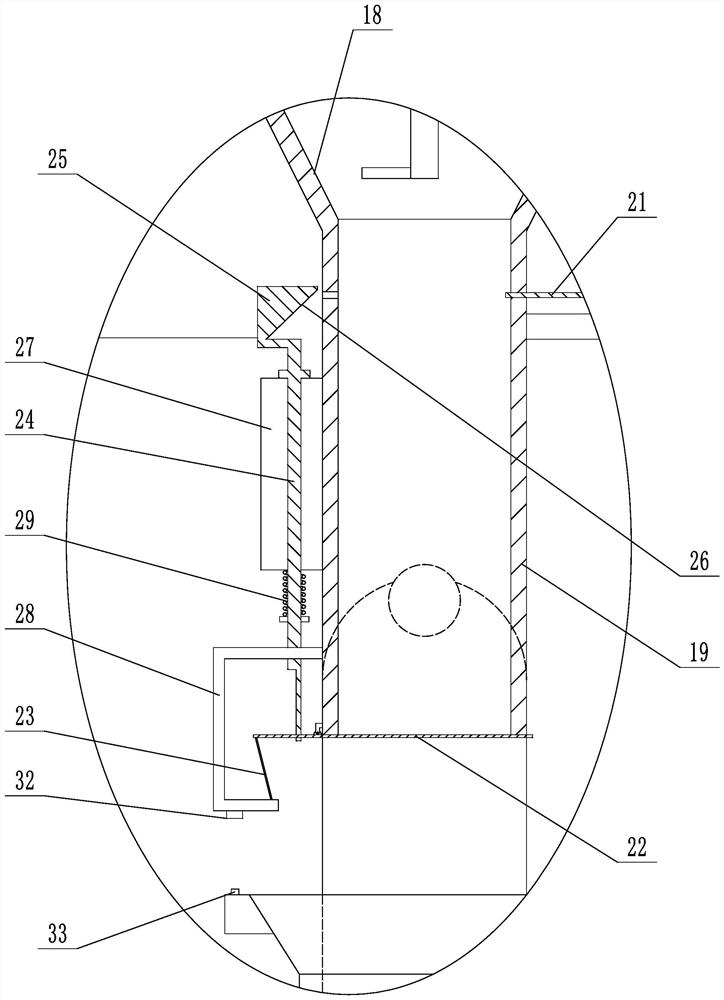

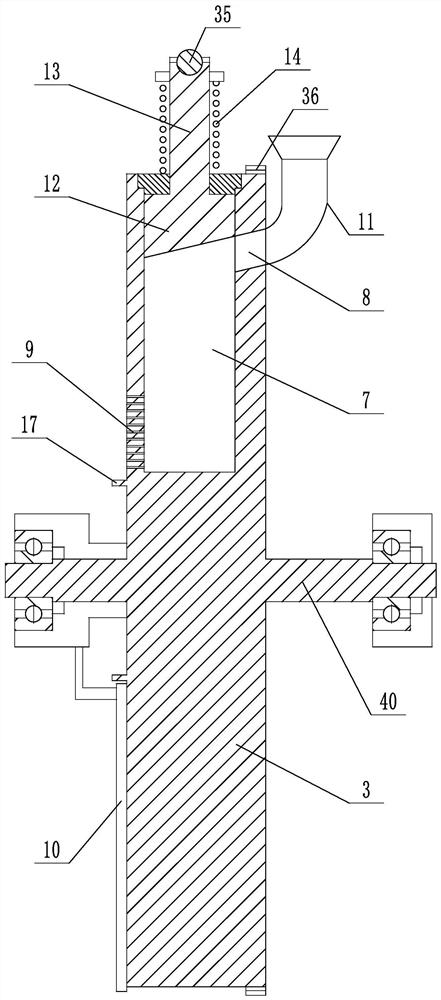

[0021] Embodiment: a kind of Chinese torreya oil press device (referring to attached figure 1 , attached figure 2 , attached image 3 ), comprising a frame 1, an oil press 2 installed on the frame, and the oil press adopts an existing screw oil press. The secondary oil pressing mechanism is installed on the frame. The secondary oil pressing mechanism includes a turntable 3, a fixed guide block 4, and a shaking guide block 5. The oil press is equipped with a slag outlet 6, and a slag delivery component is installed between the slag outlet and the turntable. The turntable is evenly distributed with three radially arranged oil extraction chambers 7, one side of the turntable is provided with slag inlet holes 8 connected with the oil extraction chambers, and the other side of the turntable is provided with several oil discharge chambers connected with the oil extraction chambers. Hole 9, the slag inlet hole is set near the top of the oil press chamber, the oil outlet hole is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com