Batten transfer processing device

A technology for processing devices and wood strips, which is applied in decorative arts and processes for producing decorative surface effects, can solve problems such as single function, immature technology, time-consuming and labor-intensive, etc., and achieve the effect of reducing labor force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A wood strip transfer printing processing device, such as figure 1 As shown, it includes a support frame 1, a support foot 2, a pull rod 3, a telescopic plate 4, a sliding device 5, a blanking mechanism 6, and an extrusion mechanism 7. The frame 1 is connected with a feeding mechanism 6, and the support frame 1 is slidably connected with a telescopic plate 4. There are square grooves in the middle of the top, front, and rear sides of the telescopic plate 4. The right side of the telescopic plate 4 is connected with a pull rod 3. The front and rear of the telescopic plate 4 Sliding devices 5 are connected to both sides, and an extruding mechanism 7 is connected to the lower left side of the support frame 1 .

[0054] When people need to transfer the wood water, first place the sticker in the square groove, then place the mold on the upper part of the sticker, then people move the parts of the unloading mechanism 6 upwards, and place the wooden strip on the parts of the u...

Embodiment 2

[0056] On the basis of Example 1, such as Figure 2-3 As shown, the sliding device 5 includes a first support shaft 51 and a pulley 52 , the front and rear sides of the telescopic plate 4 are evenly connected with the first support shaft 51 , and the first support shaft 51 is rotatably connected with a pulley 52 .

[0057] When the expansion plate 4 moved left and right, the pulley 52 was constantly rotating, and the auxiliary expansion plate 4 moved left and right, so that people could move the expansion plate 4 conveniently.

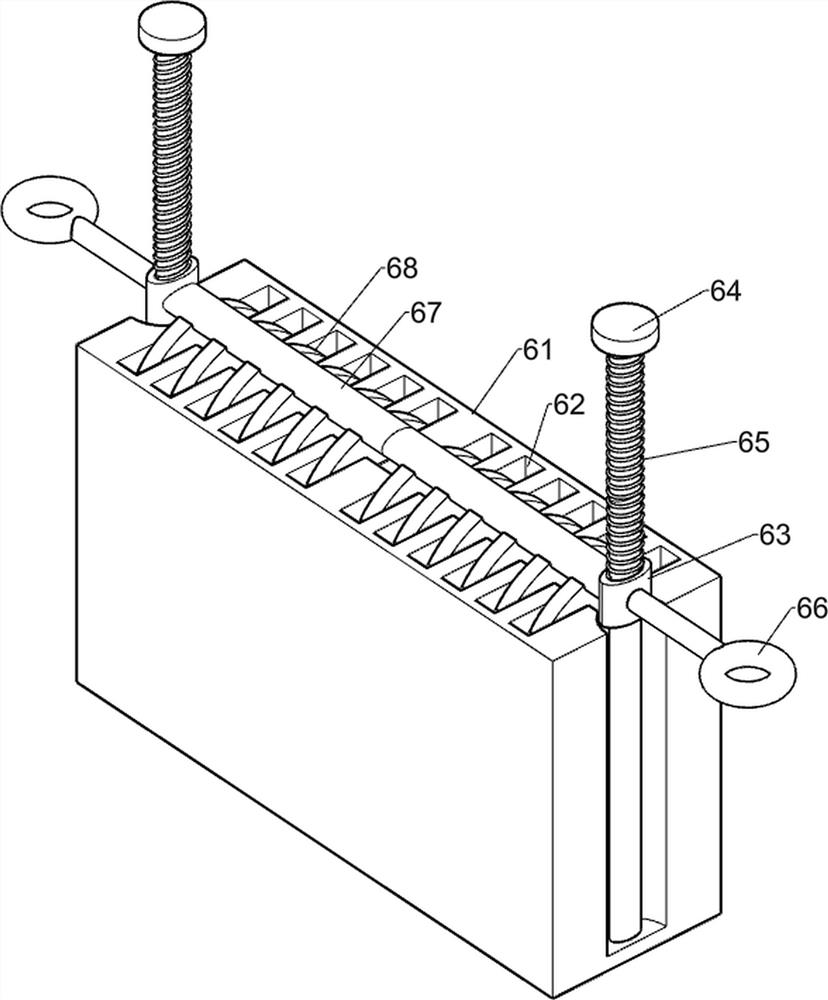

[0058] The blanking mechanism 6 includes a placement frame 61, a guide ring 63, a guide rod 64, a first spring 65, a handle 66, a connecting column 67 and a pressing block 68, and the support frame 1 top is connected with a placement frame 61 in the middle of the placement frame 61. Evenly have through groove 62, place frame 61 center and front and back both sides all are connected with guide rod 64, all slide type is connected with guide ring 63 on gu...

Embodiment 3

[0061] On the basis of Example 2, such as Figure 4-7 As shown, the extrusion mechanism 7 includes a roller 71, a cylinder 72, a gear 73 and a rack 74. The front and rear sides of the top of the expansion plate 4 are connected to the rack 74, and the support frame 1 rotates between the left side of the middle and the front and rear sides. Type is connected with roller 71, and roller 71 middle part is connected with cylinder 72, and cylinder 72 front and rear sides are all connected with gear 73, and gear 73 and rack 74 mesh.

[0062] When the telescopic plate 4 moves to the left to drive the rack 74 to move to the left, and when the gear 73 meshes with the rack 74, the roller 71 and the cylinder 72 are driven to rotate clockwise, so that the transferred wooden strip is pressed by the cylinder 72, so that The sticker and the wooden strip are fully attached, and then people can remove the wooden strip.

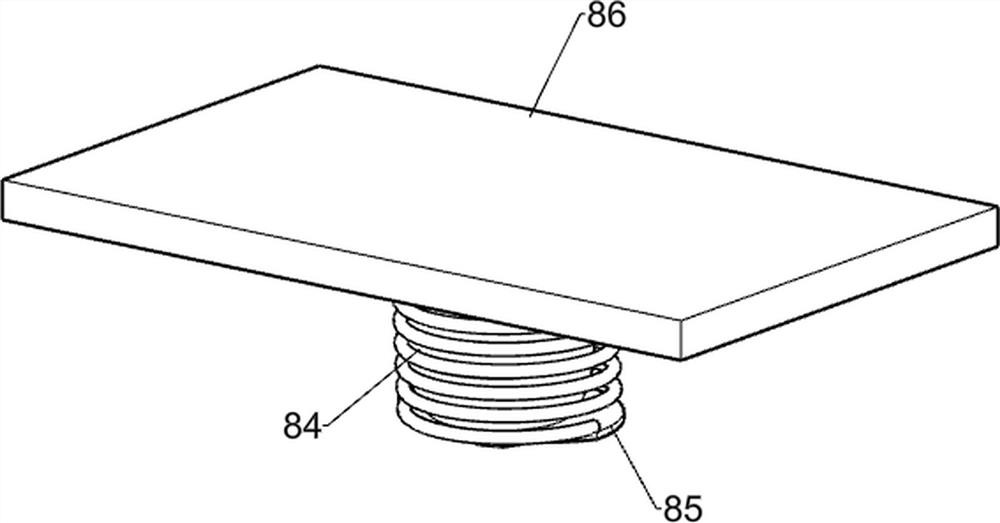

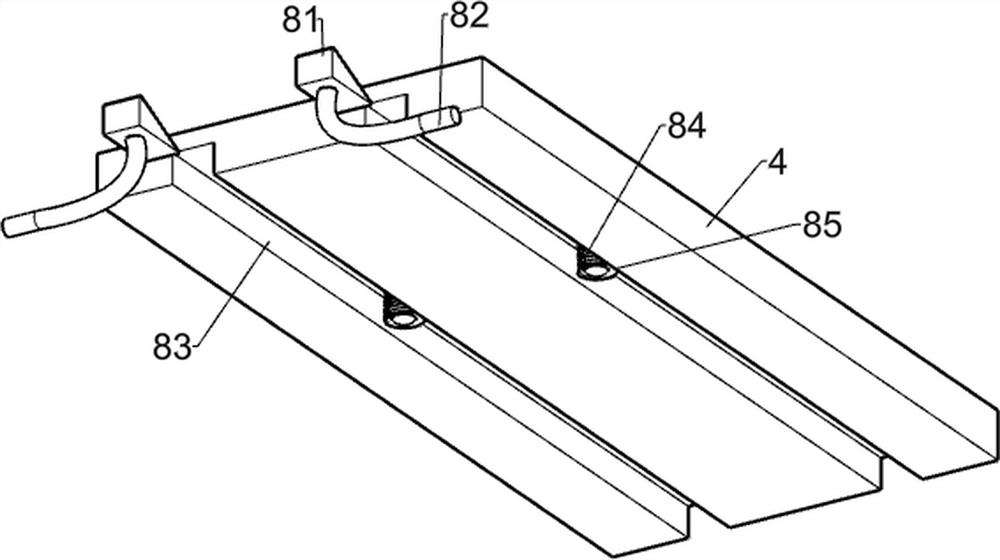

[0063] Also include push-out mechanism 8, push-out mechanism 8 includes we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com