Lifting appliance and lifting system

A spreader and hook technology, which is applied in the field of spreaders and lifting systems, can solve the problems of complex and harsh working environments, the inability to effectively observe the hooking status of the spreader, and equipment damage, and achieve the effect of simple hooking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

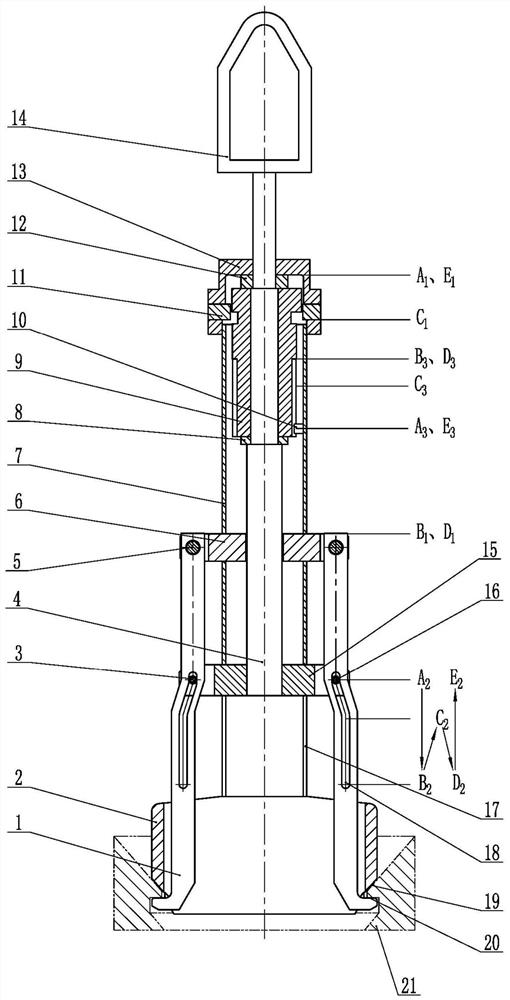

[0031] This embodiment discloses a hanger, including a hook assembly, a mandrel assembly 4, an intermediate block 6 and a housing 7,

[0032] The hook assembly includes a plurality of hooks 1 evenly arranged outside the housing 7 along the circumferential direction, and each hook 1 includes successively extending vertically in the vertical direction (that is, the direction of gravity) from top to bottom. Part 1 (from position B 1 、D 1 to position A 2 ,E 2 part), the second part bent outwards (from position A 2 ,E 2 to position B 2 、D 2 part), and the hook part (position B 2 、D 2 The following part), the second part is provided with a curved slideway 18 conformal to the second part, and the slideway is provided with a roller 3,

[0033] The middle block 6 is fixed on the casing 7 and has a plurality of overhanging structures extending to the outside of the casing 7, the outer end of each of the plurality of overhanging structures passes through the upper end of the fir...

Embodiment 2

[0036] refer to figure 1 , this embodiment provides a hoist, including a hook assembly, a mandrel assembly 4, an intermediate block 6 and a housing 7.

[0037] The hook assembly includes a plurality of hooks 1 uniformly arranged outside the housing 7 along the circumferential direction, and each hook 1 includes successively connected vertical The first part of the extension (from position B 1 、D 1 to position A 2 ,E 2 part), the second part bent outwards (from position A 2 ,E 2 to position B 2 、D 2 part), and the hook part (position B 2 、D 2 The following part), the second part is provided with a curved slideway 18 conformal to the second part, and the slideway 18 is provided with a roller 3. When the number of hooks 1 is two, it may not be possible to stably hook the equipment 21 to be lifted. Therefore, in this embodiment, the number of hooks 1 and rollers 3 may be three, but it is not limited thereto. For example, the number of hooks 1 and rollers 3 can be four ...

Embodiment 3

[0054] This embodiment provides a hoisting system, including a crane (not shown) and a spreader, the spreader adopts the spreader described in Embodiment 1 or 2, and the crane includes a crane hook (not shown), The sling includes a lifting ring 14 which is hooked on the hook of the crane.

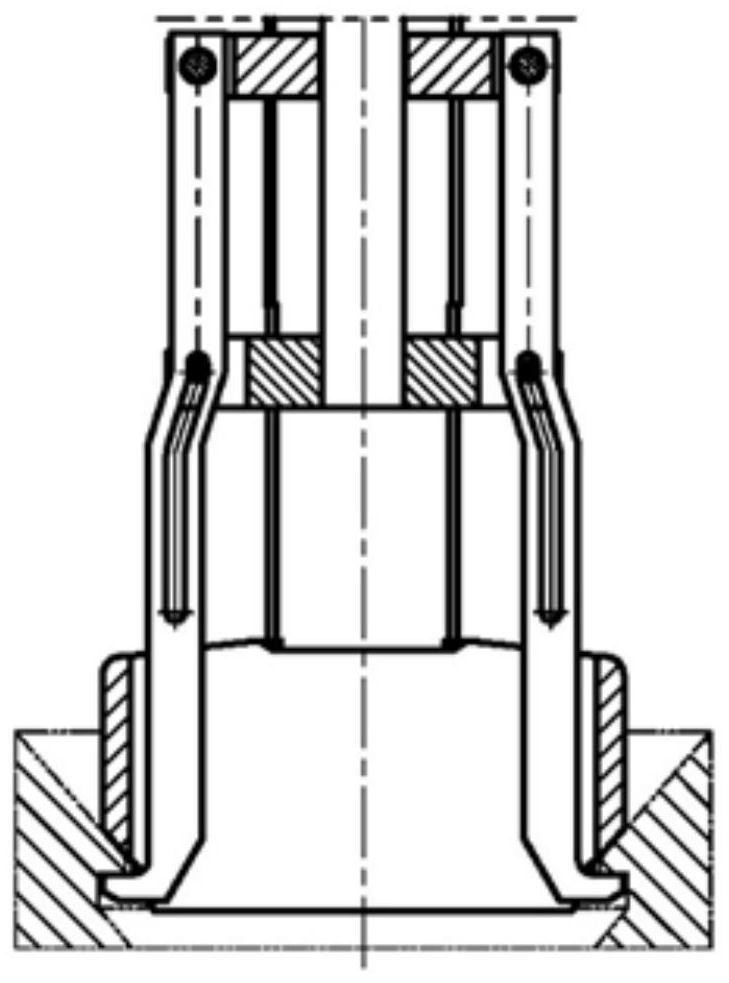

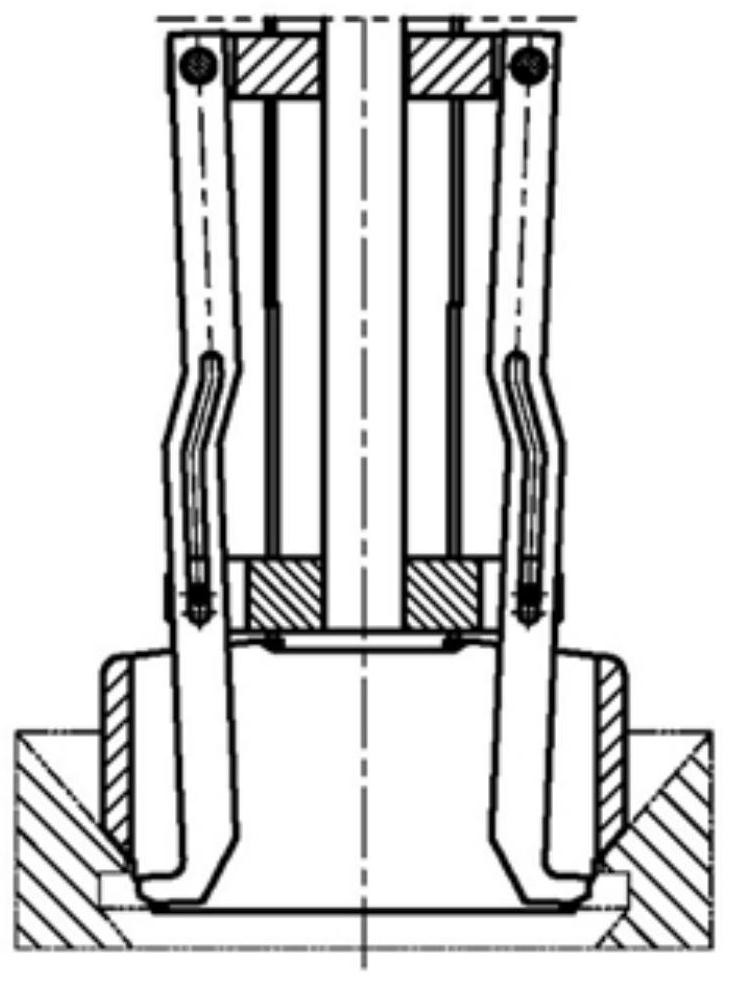

[0055] will now refer to Figure 1 to Figure 7 to describe examples of hoisting / hooking, unhooking and releasing conditions of a spreader.

[0056] refer to figure 2 , the hoisting working condition is: the lifting ring 14 is hooked on the crane hook, the mandrel assembly 4 and the cam 9 are located at the upper station of the sling, and at this time, the axial fixing member 12 is in contact with the top cover 13 (see figure 1 A in 1 ), the slider 10 is located at the lower part of the chute on the cam 9 (see Figure 5 A in 3 ), the roller 3 is located on the upper part of the slideway 18 of the hook 1 (the figure 1 A in 2 ), the second keyway 9a and the second key piece 9b of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com